The Complete Guide to Injection Mould Tooling: From Fundamentals to Advanced Manufacturing

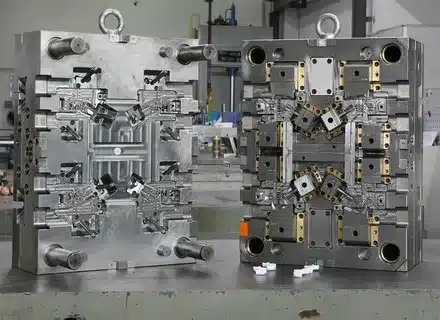

This basic guideline has discussed the fundamentals of injection mold tooling including the essential principle to advanced production business. Some

This basic guideline has discussed the fundamentals of injection mold tooling including the essential principle to advanced production business. Some

Future trends in rapid injection mold tooling are positive providing the further development of materials, process, and integration technologies paving

The process of rotational molding is one of the technologies as regards manufacturing that has stood the test of time

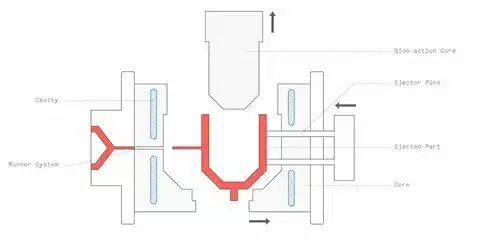

Side action injection molding is a strategic application that needs critical attention on the design needs, cost implication, and quality

Insert molding is an advanced process, which combines various materials into one part resulting in great strength and lower assembly

The key to the successful arc welding process in sheet metal welding is the ability to control the heat by

LSR injection molding combines the exceptional properties of liquid silicone rubber with the precision of injection molding to produce high-quality,

This elaborate guide discussed the most serious forms of welding defect such as porosity, cracking welds, lack of fusion, inclusion,

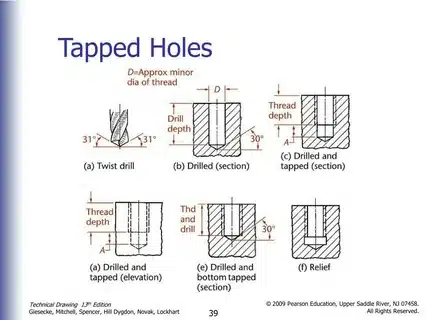

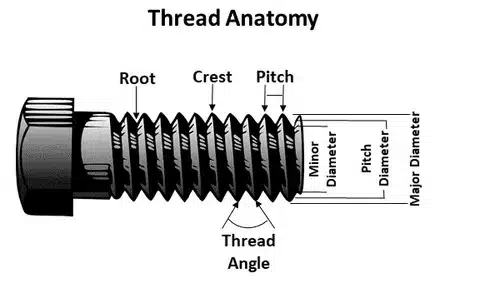

This complete book serves all the necessary details that revolve around tapped holes starting with their simple threading characteristics all

Thread machining Closely related to manufacturing processes which make up the backbone of any manufacturing establishment, thread machining is the

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

واتساب لنا