The term hybrid manufacturing is coined as the methodology that combines the flexibility and speed of 3D printing as well as the ability to big batch of materials. It presents an innovative approach that is more accessible and cheaper than usual mold making techniques for injection molded parts . Injection molding and CNC machining have long held the upper hand in the mold manufacturing space, particularly when using an injection molding machine, but 3D printing completely turns the production times, reduces material waste and enables to accomplish rapid customization. It speeds up the prototyping phase, particularly in producing complex geometry and at the same time aids low volume injection molding, for example, with consumer goods to aerospace.

How 3D Printing Enhances Mold Creation

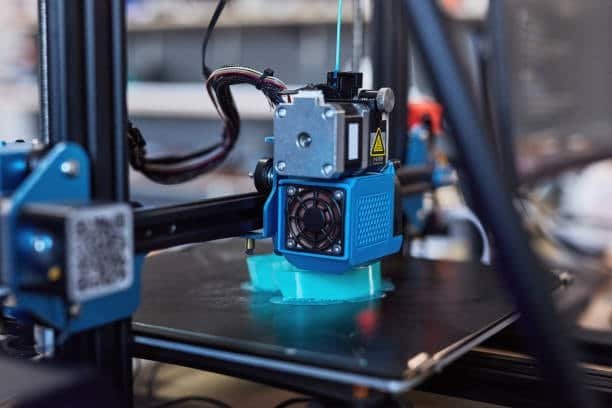

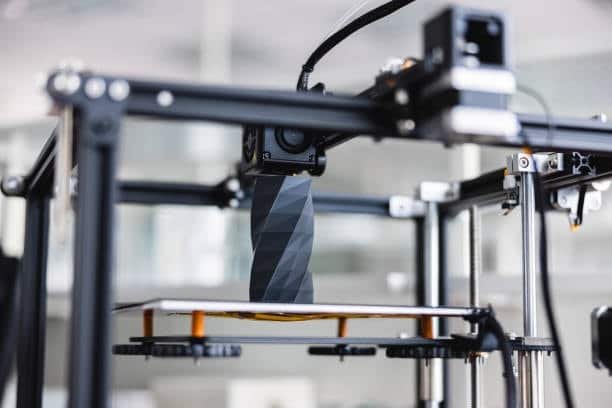

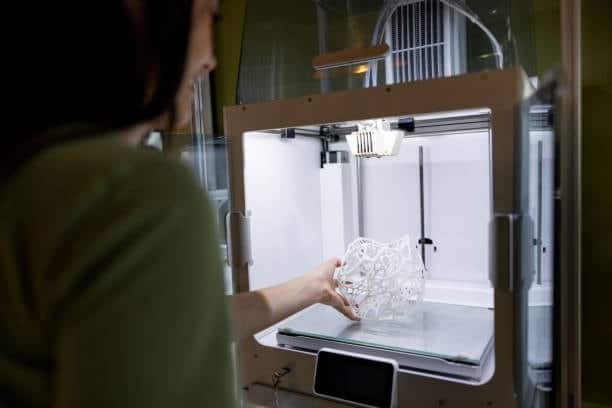

3D printing fills the role of its ability to convert digital designs into the physical forms with high accuracy as quickly as possible. Instead of doing this by subtractively carving a metal mold, these designers can now “print” a mold layer upon layer with thermoplastics or resin-based materials in the injection molding process . It greatly shortens the delay from computer to production. Additionally, it allows the production of internal geometries and surface textures that are difficult or impossible to make by traditional methods. Using 3D printer molding even the most complex and detailed mold designs can be realized with no expensive tooling and no laboring.

3D printing is the first kind of revolution applied to the digital designs that are transformed into physical forms with unparalleled speed and precision. In contrast to subtractively carving metal mold, designers can now print a mold layer by layer utilizing thermoplastics or resin based materials. It significantly cuts down on time spent between design and production, and thus speeds up the process. Additionally, 3D printing enables the making of complex internal shapes, complex parts, or intricate surface textures that cannot be carried out always via traditional techniques. Through 3D printer molding, literally the most fine and complicated mold designs are obtainable without expensive tooling or exhausting work, offering a low cost and flexible option for various utilizes.

Materials Used in 3D Printer Molding

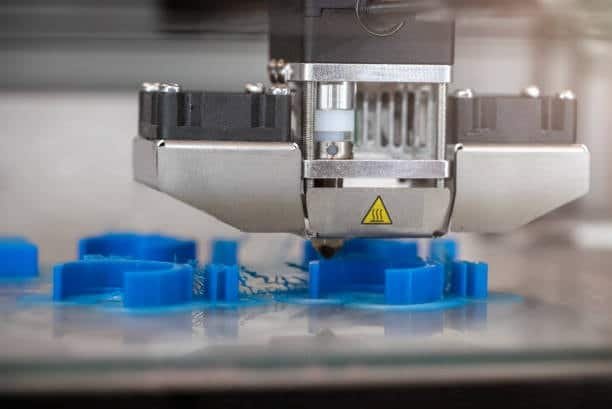

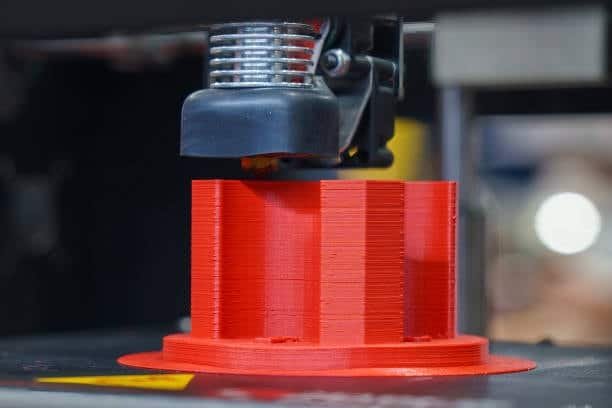

Greatly determining the success of 3D printer molding is the choice of materials. FDM (Fused Deposition Modeling) printers like any other printer uses thermoplastics like PLA, ABS, Nylon that are quite durable and convenient to use compared to traditional metal molds . For low temperature and low pressure molding applications, including the use of mold inserts, these materials will prove to be suitable. However, high stiffness materials such as Stereolithography (SLA) and Digital Light Processing (DLP) printers based on photopolymer resins that provide much better detail and surface finish. Reinforced composite filaments or even heat resistant polymers can be used by engineers for more advanced applications so the mold can survive repeated use as well as harsher processing conditions, providing enhanced wear resistance .

A material choice decides the success of 3D printer molding operations. FDM printers work with durable thermoplastics consisting of PLA, ABS and Nylon which operators find straightforward to handle compared to traditional metal tooling . Low-temperature and low-pressure molding, including low run injection molding, works best with these materials as they prove ideal for these conditions. Because SLA (Stereolithography) printers and DLP (Digital Light Processing) printers work with photopolymer resins customers gain access to superior detail and better surface finish suitable for dental molding as well as jewelry and industrial part production. The mold needs stronger materials like reinforced composite filaments or heat-resistant polymers when operating under demanding situations because these materials support multiple uses and tolerate challenging processing requirements. The continuous research of specialized materials unlocks new possibilities to develop molds that fulfill diverse design considerations, performance needs, and durability specifications.

Benefits of Using 3D Printed Molds

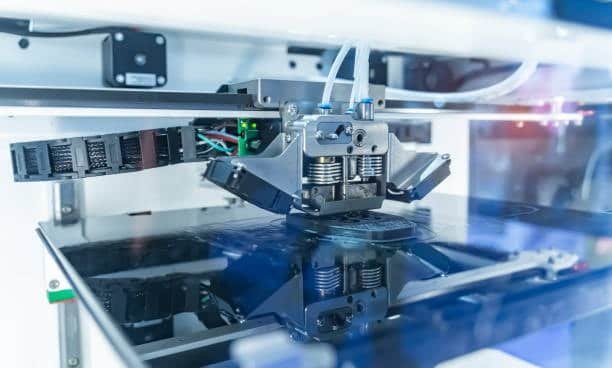

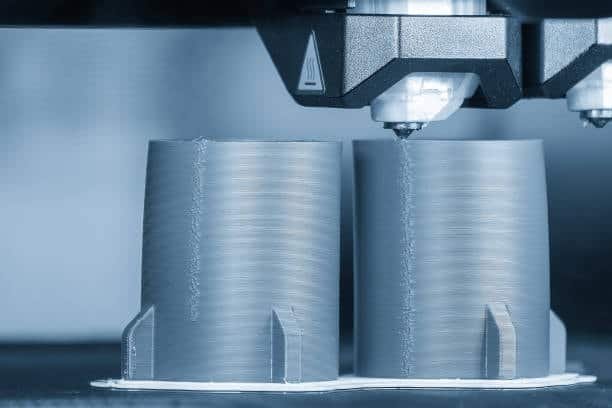

The main benefit of using 3D printed molds is the drastic reducing in lead time. The building of a mold traditionally takes weeks or even months, relying on the complexity of the design and the specifications of the injection molding machine . On the contrary, a 3D printed mold can be made in a matter of hours or days. A fast product development timeline allows for rapid pace in development and helps to market faster. Also, it minimizes the waste of the raw materials involved, and 3D printing also reduces their quantities. It also lets you experiment more, creating, testing, and destroying several versions of a mold very quickly with low costs. Due to this, it is especially beneficial in the prototyping, custom components manufacturing, and low run injection molding markets.

3D printing of molds allows design flexibility so manufacturers together with designers can develop original and non-standard designs beyond the limitations of traditional tooling processes. Additive manufacturing simplifies the creation of difficult complex parts and intricate undercuts and internal channels, unlike traditional injection molding which usually encounter obstacles in the manufacturing process. The versatility of additive manufacturing enables producers to achieve greater dimensional accuracy and product functionality together with improved visual results at a high development speed level. Business success through 3D printed molds happens because they enable rapid design feedback processing and market change adaptation giving organizations an edge which in turn establishes these molds as essential components of modern agile production processes.

Applications Across Industries

3D printer molding has been adopted into many different industries that all use the technology in a personalized way to solve a certain problem. It is used by the engineers of the automotive sector to create prototype parts and components, before the commitment of expensive tooling. Custom prosthetics, surgical models and dental appliances in the healthcare industry have been manufactured from 3D printed molds that are molded to that of a patients anatomy. 3D printer molding is exploited by the fashion and design world for affluent weaving, shoe molds, and intricate textile patterns, significantly reducing tooling costs . The technology is applied in aerospace, where lightness and precision are key; the technological method allows creating structural components of lightweight with precision. Even in the food industry, chefs and product developers are now utilizing molds printed by 3D printer to create artistic and uniform presentations.

Educational institutions together with research facilities have incorporated 3D printer molding as an interactive educational and experimental technology. Through 3D printer molding educational institutions enable students to develop prototypes from theoretical concepts during their studies of design engineering and material science. Individual researchers obtain laboratory tools while also getting testing apparatuses and experimental components fabricated rapidly to speed up their research cycle. The entertainment sector particularly film and games sector utilizes 3D printed molds for creating precise and detailed props and costumes along with stage designs, often for small batch production . 3D printer molding demonstrates its far-reaching versatility which significantly improves mold making and leads to major industrial advancement by producing customized industrial solutions to complicated production issues.

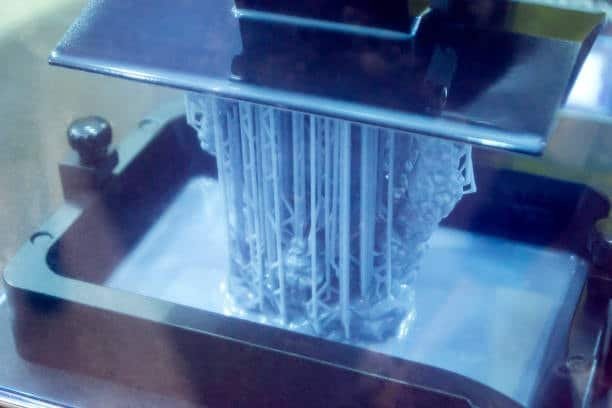

Creating Functional Prototypes with 3D Printed Molds

The development of functional prototypes stands as one of the main powerful applications enabled by 3D printer molding. Using 3D printer molding manufacturers achieve product testing of form and functionality prior to building expensive production tools. The production of functional product simulations proceeds through 3D printed molds that allow quick casting of silicone, urethane casting or low-melting-point metals. The method enables designers to complete real-time changes in which they enhance their product repeatedly using user input and test results, ensuring an excellent surface finish . Money savings and better end results happen simultaneously because design flaws become obvious before production begins.

As a result of this prototyping method users from different professional roles together with designers and engineers along with project stakeholders get to engage with tangible models during early development phases which supports a continuous cycle of product development. This hands on feedback will speed up making decisions, cut down on avoidable re revisions and improve final design confidence. Manufacturers solve problems in solving the functional product design, resolution of complications regarding product performance, wall thickness tight tolerances durability, and user experience through the utilization of real world use scenarios. Therefore, 3D printer molding not only reduces the time, cost and path between the idea and the launching of molded parts, but also increases the overall product quality and increases market readiness of new products in a time and cost effective manner.

Post-Processing and Mold Preparation

3D printed molds provide great versatility but users need to do additional finishing steps to reach their desired result. Surface processing techniques including sanding alongside polishing and coating help increase the lifespan together with surface quality and dimensional accuracy of 3D printed molds particularly useful for molding both detailed objects and transparent parts. Support structures together with casting the mold in heat-resistant materials extend the lifespan and functional capabilities of the mold to create the desired part . Molds function as middle forms to create engineering patterns and silicone molds thus establishing subtractive and additive techniques into a manufacturing sequence, often coming in two halves .

The incorporation of 3D printed molds with conventional molding processes enables users to produce parts and achieve best results from a combination of artistic freedom and production efficiency. The productive use of 3D printed molds includes their function as master patterns for producing urethane casts and their ability to create precise silicone molds, particularly in injection molding . The production timeline gets shorter because of rapid prototyping capability and versatile design modifications and because the method produces custom parts efficiently, reducing tooling costs . A 3D printed mold’s scope is widened by users as they use finishing methods and are more comfortable with material compatibility, driving this tool further as an indispensable lever between digital design and physical production.

Limitations and Considerations

The technological strength of 3D printer molding faces several constraints in its operation. Standard desktop printers generate mold materials whose mechanical properties fall slightly shorter than machined metal molds in terms of strength and heat resistance. The limitations of 3D printed molds include their inability to withstand high pressure injection molding, which can be a challenge for mass production, as well as acting under extremely high temperatures. Molded part quality will suffer because of visible layer lines and micro-gaps at the mold surface which necessitates subsequent finishing operations. The printer bed size imposes design limitations which create difficulties for creating expansive mold structures unless the user possesses specialized printing tools. The decision to use 3D printer molding requires evaluation of these factors for any particular application.

Continuous innovation work to minimize performance differences in 3D printed molds. Manufacturers use enhancements in both high-performance thermoplastics and resin formulation and composite materials to strengthen 3D printed molds while extending their thermal resistance as well as durability. Techniques related to post-processing such as resin coating and surface polishing and thermal treatments now experience optimized operations to boost mold integrity and surface finish quality. Industrial 3D printers with expanded printing capabilities and multiple material functions now exist in the market which allows more complex and bigger mold designs to be developed. 3D printer molding transforms from a specialized technology into a cost effective commercial solution for challenging manufacturing needs because these technologies will keep advancing.

Future Trends and Innovations

The future of 3D printer molding is assured as it is propelled forward with continuous improvements on the basis of enhancing its functionality as well as removing drawbacks in its present form. There is now more emerging advances from multi material printing and hybrid manufacturing that make it possible to make more complicated, functional molds with greater precision. However, the strength and durability of 3D printed molds have also increased, following new design guidelines, due to the creation of advanced printable materials such as heat tolerant polymers and metal polymeric composite.

At an increasing pace, software tools for generative design and simulation are allowing engineers to work on mold structures for ideal performance in parallel, before they have even been printed. Also, all these digital enhancements help reduce the design cycles and the production time. With 3D printing becoming more and more accessible and cheaper, especially with the advancements in the injection molding machine technologies 3D printer molding is destined to be a core technology of global digital manufacturing from rapid prototyping to the full scale production.

Sustainability and Eco-Friendly Impact

Manufacturing is going in Sustainable direction and 3D printer molding suits perfectly with the goal of being environmentally friendly. It helps reduce the amount of material waste by facilitating local production, which in turn helps minimize carbon footprint of traditional manufacturing, including conventional mold making, and shipping. On top of that, it allows using printing materials that are biodegradable or recyclable, like PLA or reclaimed thermoplastics, which supports a circular production model for producing plastic parts . 3D printer molding is adopted by companies who can test designs with fewer resources and more sustainable production products, effectively streamlining part removal and being able to deliver earlier to market needs.

The digital characteristics of 3D printer molding minimize inventory needs because makers can produce items upon demand thus erasing the requirement for large stockpiles and the dangers of producing beyond necessity. The lean manufacturing system used in 3D printer molding supports green policies by optimizing the mold cavity design ecause it decreases warehouse energy use and environmental impact. Future reductions in both energy-efficient printer and sustainable printing material development by industry stakeholders will lead to a continued decrease in additive manufacturing carbon footprint, making it the best solution for environmentally conscious production . The environmental improvements made in 3D printer molding provide businesses with operational advantages because the market demands both sustainable procedures and new production techniques.

الخاتمة

The Multiprinter Modelling will become an important part of the modern production workflows as 3D printer molding is advancing. It enables development, sustenance of both innovation and sustainability through its streamlining of development, reduction of waste and its ability to adapt to diverse design needs for mass production . As this technology gains wider industry adoption, it will be critical in shaping the future of manufacturing as a technology better suited to the faster, more flexible ways of manufacturing to meet a global market’s dynamic demands.

The integration of multiprinter modeling with traditional production lines enables exceptional product customization together with quick prototyping which shortens new product time-to-market durations. This functionality enables manufacturers to rapid prototyping as well as functional prototype testing with live adjustments that do not cause heavy tooling expenses or extensive production delays. The ongoing evolution of 3D printer molding leads toward dispersed manufacturing through local hubs, where the integration of ejector pins is crucial in both cutting manufacturing emissions and supporting immediate product manufacturing. The combination of multiple printers in modeling applications improves operational efficiency because it supports sustainability initiatives along with global production capabilities in modern manufacturing.