Meta Description: Discover the depth of cut axial in the CNC machining by implementing this profound guide, focusing on the end mill used in the process . Get to know about its importance, the factors that affect it such as cutting speed , calculate it and finally obtain the best ways of minimising the machining process.

Introduction to Axial Depth of Cut

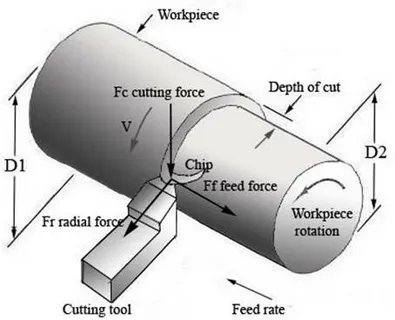

Axial depth of cut This is a very important parameter in CNC (Computer Numerical Control) machining as it is the distance a cutting tool, defined by its tooth configuration, cuts into the material along the axis of the tool. This is a critical measure towards establishing the machining process efficiency and effective, especially when combined with the cutting speed . Knowledge of an axial cutting depth may result in high production rate, better surface finishes, as well as a prolonged life span of the tool.

Understanding CNC Machining

CNC machining involves subtractive manufacturing process through the use of programmed commands to regulate machine tools in a milling operation . The technology creates high precisions and repeatability in the manufacture of complex parts. CNC machines have been useful in accomplishing a number of tasks, such as milling, turning, drilling and grinding hence its versatility in contemporary manufacturing.

Importance of Axial Depth of Cut

The longitudinal cut depth is important in more than one way of machining: one point being its effect on productivity.

- Material Removal Rate (MRR): Higher material removal rate (MRR) can be achieved by making deeper cut thus resulting in faster production time.

- Tool Wear: Depth of cut influences the rate of wear of the cutting tool. Finer cuts may result in more wear and chances of breakdown of the tools.

- Surface Finish: The surface finish quality is determined by the depth of the cut, deeper cuts will produce a poorer finish.

These factors need to be understood in order to get the best in terms of machining processes and desired outcomes.

Factors Influencing Axial Depth of Cut

The optimal axial depth of cut may be dependent upon several factors such as radial adjustments to the cutting tool, and it should not exceed the max depth recommended for the maximum chip thickness. .

1. Material Type

The materials cut differently, particularly when considering the type of metal being processed . The harder materials (steel or titanium), in turn, cannot generally take a deeper cut than the soft ones (aluminum). Knowing the material properties is important in the selection of the proper depth of cut, particularly regarding particularly regarding the amount of metal removal rate and the depth of cut. .

2. Tool Geometry

The maximum depth of cut is affected greatly by design and geometry of the cutting tool, especially the sharpness of the cutting edge . The more sharp are the edges of the tools and the right rake angles they possess, the deeper cuts the tools will accept.

3. Machine Capability

Stiffness and strength of the CNC machine plays an important role in deciding the ultimate depth of cut, as it can help minimize deflection during the process. Rigid machines are able to resist stronger cutting powers leading to deeper cuts without losing its precision.

4. Cooling and Lubrication

Effective machining can be improved when done properly through cooling and lubrication so as to minimize the heat and friction, while carefully managing chip thickness . This will be able to achieve further reductions and still preserve the integrity of the tools and good surfaces.

Calculating Axial Depth of Cut

In order to determine the axial depth of cut, you may utilize formula below, or alternatively, a cut calculator can be employed.

t=D−d/2

Where:

- t = depth of cut

- D = size of the workpiece diameter

- d = the diameter of a tool

This formula is one which is useful in finding the correct depth of cut depending on the size of tool and work piece size.

Recommended Axial Depths for Different Materials

The best axial depth of cut is also dependant on the material machined, and should align with the recommended cutting speed and cutting diameter for optimal results spindle speed. . Following is some general advice:

- Aluminum: 2-3 mm

- Steel: 1 2 mm

- Titanium: 0.51 mm

- Plastic: 3-5 mm

These values can be taken as working points, and they might have to be modified depending on certain machining conditions and needs tool diameter.

Effects of Axial Depth of Cut on Tool Life

Tool life has direct influence over the axial depth of cut. A more severe incision may cause:

- Increased Tool Wear: Greater cutting forces will take place with deeper cuts which can hasten the wear of the tool.

- Shorter Tool Life: Deeper cuts used incorrectly may cause the tool to expiry ahead of schedule.

Intuitive evaluation of the depth of cut with other machining parameters including feed rate and cutting speed is critical to the tool life and in ensuring machining productivity tool engages.

Optimizing Axial Depth of Cut

In order to obtain the best machining outcomes, the following are some ways of optimizing the axial depth of cut and enhancing productivity :

1. Experimentation

It is also important to carry out tests to determine the right depth in which certain materials and tools are handled. Machining prescriptions may be changed depending on knowledge-based data on the depth of cut, resulting in better results in machining climb milling.

2. Adjusting Feed Rate

Feed rate can also be increased to offset the shallower cuts as this helps retain the material removal rate without having to increase tool wear. The most important aspect in efficient machining is the right balance between depth and feed rate.

3. Monitoring Tool Condition

To ensure machining quality, it may be recommended to regularly check tools to wear and replace them when this happens. Such a process can be simplified by a tool management system.

Axial Depth of Cut in Different Machining Operations

axial depth of cut and maximum chip thickness in different machining operations:

1. Turning

The axial depth of cut is significant in the question of attaining desired diameters as well as surface finishes in turning operations, particularly in relation to the cutter diameter used, and correct adjustment of the cutting diameter can increase efficiency of the turning process.

2. Milling

The axial depth of cut has an impact on the engagement of cutter to the work in the milling process, which is influenced by the chip load . The depth and cut width can be adjusted to maximize the cutting action and give a good surface.

3. Drilling

The depth of cut in drilling work constitutes the depth of a hole and quality, similar to a slot cut in milling . The right axial depth is important to get accurate holes dimensions.

Common Mistakes in Setting Axial Depth of Cut

There are some errors which ever can happen in establishing the axial depth of cut, particularly related to radial adjustments :

1. Overestimating Depth

An excessive cut depth may cause tool breakage as well as poor part quality. But it is also important to remain within the limits that have been recommended to the material and tool.

2. Ignoring Material Properties

Ignoring the hardness of a material and its features may lead to a bad machining process. It is always advisable to gauge the material to realize the depth of cut.

3. Neglecting Machine Limits

it is possible to cause inaccuracy and failure by exceeding the capacity of the machine. It is essential to know the specifications of the machine so that proper cutting parameters could be established.

The Role of Technology in Managing Axial Depth of Cut

Technological breakthroughs have also made axial depth of cut management far much better by incorporating techniques like chip thinning.

1. CNC Software

Contemporary CNC programs are capable of optimizing the parameters of cutting depending on the specifications of material and tools. This minimizes adjustments done manually and increases efficiency on machining.

2. Sensors and Feedback Systems

Real-time monitoring systems are able to make dynamic depth of cut adjustments where the response of the material and the tool wear are measured. This technology aids to keep and maintain the best cutting conditions in the entire process of machining.

Case Studies: Successful Applications of Axial Depth of Cut

1. Aerospace Industry

In aerospace industry, the deepest depth of cut (axial) should be optimized, especially when working with large doc, in order to machine complex parts at high precision. Fine-tuning of this parameter has been reported to lead to substantial gains in production efficiency and the quality of the parts the manufacturers are producing.

2. Automotive Manufacturing

Organizations within different sectors usually undertake a trade off between depth and speed, often requiring tools with more flutes to enhance efficiency. They have realized quicker cycle timing and cost reduction through use of best practices in any aspect of axial depth of cut.

Best Practices for Setting Axial Depth of Cut

To guarantee high quality machining, put to consideration the following best practices:

1. Start with Manufacturer Recommendations

Recommended cuts should always be referred to the guidelines given in the tool manufactures. The given recommendations are highly tested and may be taken as a solid ground.

2. Use Simulation Software

The simulation software will assist in visualizing the process of machining and thus determining some possible problems prior to actual machining. This is cost effective since errors will be avoided.

3. Continuous Learning

Ensure you are always at the edge of what is going on in the industry and in the knowledge of machining technology. You can develop your techniques and increase the effectiveness of machining by continuous education.

الخاتمة

In CNC machining, axial depth of cut is an important parameter which greatly determines production rate, life of tools and surface finish, alongside radial depth of cut . With the help of knowing the factors that affect this parameter and following the best practices, manufacturers can then optimise their machining operations to achieve improved outcomes.