CNC Machining & Milling: The Ultimate Guide to Precision Manufacturing Technology

CNC machining and milling have transformed manufacturing from an art form dependent on skilled craftspeople to a precise science leveraging

CNC machining and milling have transformed manufacturing from an art form dependent on skilled craftspeople to a precise science leveraging

Mill and turn, however, are key engineering methods that have evolved to suit different production calls. Different motions are applied

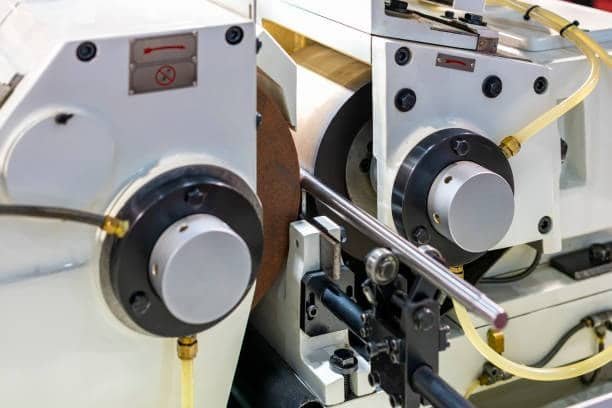

Put in other words, the centerless grinding process allows the manufacture of precisely a-shaped parts without the use of default

In simple terms, CNC screw machining offers a quick and highly accurate way to produce screws and threaded components, thanks

As a whole, CNC fixturing plays a significant role in fixating workpieces prior to machining hence sustaining consistent positioning during

In conclusion, low volume machining can help manufacturing precise high quality parts, in small quantities. Appearing in a wide range

As overall, Delrin as a material stands out as a valuable one because of its excellent properties, including, high mechanical

In short, small parts manufacturing utilizes a wide range of approaches such as computer numerical controlled machine cutting, injection molding,

Metal materials are vital in modern manufacturing and technology in short. The wide range of their properties, the strength, malleability,

In recap, High-Density Polyethylene (HDPE) has a melting temperature lying in between 130°C and 137°C, creating the conditions for a

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

واتساب لنا