Types of Metal Cutting Machines: The Complete Guide to Modern Manufacturing Powerhouses

Metal cutting machines encompass a vast array of technologies designed to transform raw metal into precisely engineered components. Traditional machines

Metal cutting machines encompass a vast array of technologies designed to transform raw metal into precisely engineered components. Traditional machines

Cutting tools form the backbone of lathe machining operations, directly influencing the quality, efficiency, and economics of the manufacturing process.

Cutting fluids are specialized liquids that provide cooling, lubrication, chip removal, and corrosion protection in metalworking processes. They come in

Fixture design in these tools helps to guarantee that machining is performed accurately and securely. The main achievers here, thanks

CNC machining and milling have transformed manufacturing from an art form dependent on skilled craftspeople to a precise science leveraging

Essentially, the carbon fiber machining is a specialized method appropriate for its difficult material characteristics. Classic to the success is

In summary, both feed rate and cutting speed are important components that need to have an exact fine tuning in

Mill and turn, however, are key engineering methods that have evolved to suit different production calls. Different motions are applied

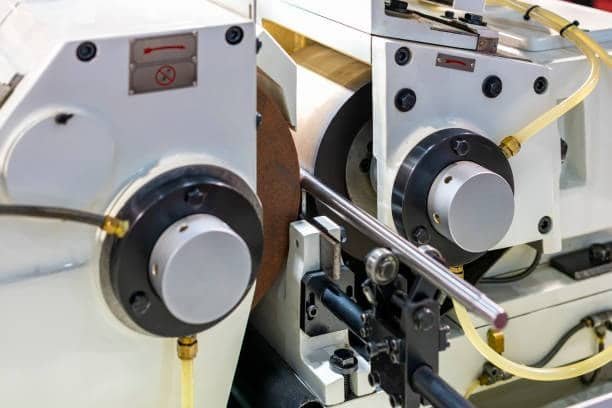

Put in other words, the centerless grinding process allows the manufacture of precisely a-shaped parts without the use of default

In simple terms, CNC screw machining offers a quick and highly accurate way to produce screws and threaded components, thanks

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us