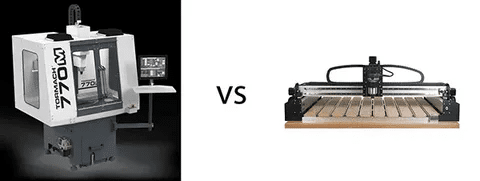

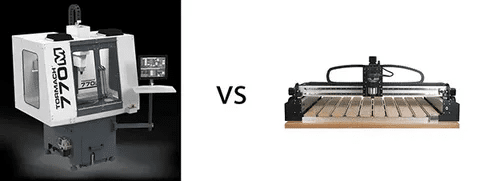

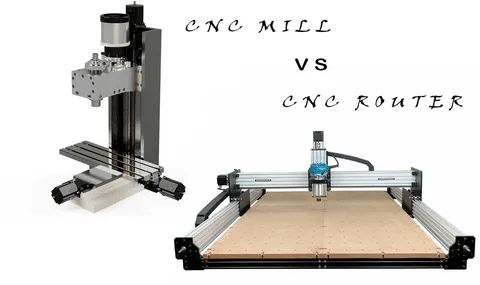

It is very important to learn major distinctions between CNC routers and milling machines as soon as manufacturers want their production to be the most precise and efficient. This guide covers two technologies to enable you to make exemplary choices concerning your manufacturing requirements.

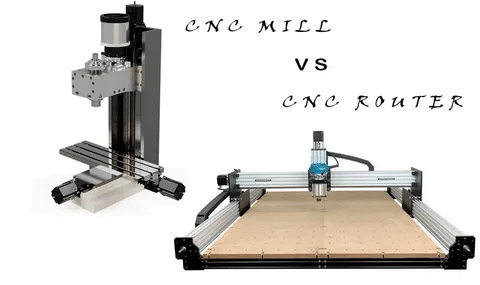

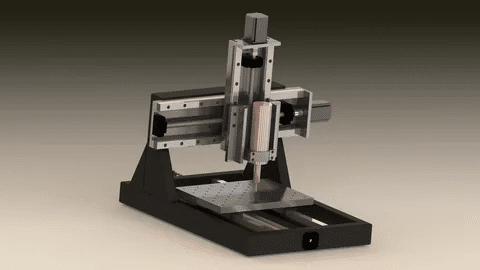

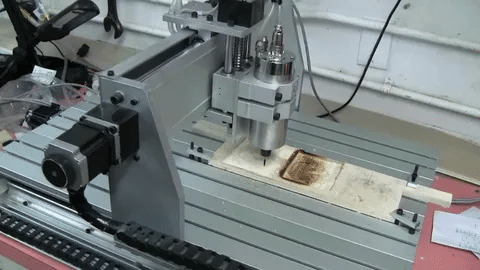

What Is a CNC Milling Machine?

A CNC milling machine is an ultra-accurate production resource where a workpiece is subjected to cutting parts operated by a computer. Having several axes (usually 3, 4 or 5), these machines can be used with all kinds of materials: metals, plastics, composites.

The CNC milling machines are of high precision work as they can work with tolerances as close as that of +0,001 mm. They are designed using the heavy duty spindles and rigid frames which are capable of supporting the cutting forces involved in the metal cutting processes. These machines have cutters with rotating cutting parts also known as end mills that move along pre-specified paths producing complex geometries, holes and slots, as well as surface finishing.

The main peculiarities of CNC milling machines are the following:

- Fast spindle turnings (more than 30,000 RPM up to 40,000 RPM)

- Accurate positioning system

- Computerized tool changers

- Heat management systems Coolant systems

- Safety and chip containment by enclosure of work areas

What Is a CNC Router?

A CNC router is an automated machine that cuts in a computer-driven environment and is mostly used with materials that are less tough like wood, plastic, metal, foam, etc. Such machines have a revolving spindle which moves over a set of programmed movements to cut, carve or engrave on materials.

CNC routers are large in comparison to work area of milling machines and are designed to act at high speed and highly economical when utilizing sheet material. They are very good at cutting intricate 2D profiles and doing 3D carving on materials not highly sensitive to the cut side and not demanding the extreme precision or cutting forces of metal cutting.

Typical features of CNC routers are:

- Big workbenches (Usually 4 x 8 or bigger in size)

- Vacuum hold-downs Vacuum hold-down systems

- Dust collector systems

- Open-frame design so it is easy to load materials

- Fast spindles specialized in wood and plastics cutting

- The Main Differences between CNC Milling Machine and Router

CNC Milling Machine vs Router: Key Differences

Material Compatibility

CNC Milling Machines are good at milling hard metal like hard steels, aluminum, titanium and hard tool steels. It is also able to work with engineering plastics and Ceramics, where tight tolerances are needed.

The CNC Routers are more suitable on the softer materials such as wood, MDF, plastics, foam and thin sheets of aluminum. Some heavy-duty routers are capable of performing light metalwork, but none is suitable to production metal cutting.

Precision and Tolerance

CNC Milling Machines provide a better precision having average tolerances of 0.001 mm and 0.005 mm. They are most suitable in precision mold components as well as connector parts because of the rigid build and high accuracy positioning systems.

The typical tolerance of a CNC Router is usually in the range of +/- 0.1mm to +/- 0.25mm, and this is good enough in woodworking as well as most plastic uses plenty of applications, however, this is not applicable to precision mold work.

Speed and Efficiency

The CNC Milling Machines are application-driven by rather focusing on accuracy than speed of feed rates which are optimized to ensure the removal of materials. They are used on low run production of highly detailed parts.

CNC Routers are known to be fast and efficient and have very high traverse rates and high material removal rates when using softer materials. They are good at 2D cut parts of high volume.

Construction and Rigidity

CNC Milling Machines are rigid and heavy weight as they are made of cast iron or steels, which help to reduce vibrations and deflection whenever cutting is in progress.

CNC Routers Remarkably, CNC Routers are most often constructed of light frames (aluminum or steel tube frames), given priority to workspace accessibility and ease of material flow, over structural rigidity.

Tooling and Spindles

CNC Milling Machines employ high quality tool holders and may drive a variety of cutting tools such as micro end mills, and large face mills. The spindles can be used in high speed finishing as well as heavy roughing.

CNC Routers usually exploit router bits and other special cutting components which are specifically created to utilize wood and plastic materials. The spindles provide high-speed softer materials cuts.

Choosing Between a CNC Milling Machine and a CNC Router

Consider a CNC Milling Machine When:

- An engineering hard plastic or a metal Working with metals or hard engineering plastics

- Tolerances of 0.01 mm or less need to apply

- Mold insert or connector manufacturing precision

- It has small-to-medium batch production normalcy

- Tight tolerance complex 3D geometries are required

- Employing forces needed to make cuts and solid structures

Consider a CNC Router When:

- The key material is either wood, soft plastics or foam

- Processing of large sheet material is popular

- There is a need of high-volume manufacturing of cut 2D parts

- There are fewer demanding requirements of precision (plus or minus 0.1 mm or higher)

- Rapid prototyping of design idea is desirable

- The budget limitation favours a less up-front investment

تطبيقات الصناعة

High precision CNC milling machines are normally preferred for precision mold manufacturing, automotive connector manufacturing and medical device parts such as connectors, etc. because the required tolerance and surfaces finish that is required in these applications can be achieved.

CNC routers are specialized in woodworking, sign making, prototyping and general scale cutting in situations when the thickness and precision demands of the material being cut is not critical.

Advanced CNC Milling Services and Precision Manufacturing

Contemporary high precision manufacturing insists on effective use of equipment that can cope with an ever more rigorous set of needs. To achieve higher tolerances required with critical applications in auto, medical, and semiconductor industries, advanced CNC milling providers have added multi-axis-machining, in-process-measurement and, specialty-tooling.

Factors to be considered when choosing to use machining services include:

- Quality management system and ISO certification

- Equipment potential and maintenance procedures

- Previous practice in analogous applications and materials

- Support to design for manufacturability (DFM)

- Delivery Performance and Supply chain reliability

When it comes to precision mould elements and those parts that connect, the overall superior equipment, technician persons, and quality inspection guarantees uniform quality that is globally agreed upon in GB, JIS, DIN, and AISI standard provisions.

الخاتمة

Whether you would want to use either CNC router or milling machine largely depends on the material you need, the amount of precision you require, as well as the volume of work. CNC milling machines are more accurate and more consistent in machining hard materials and metal, and, therefore, CNC milling machine is useful in making high precision molds and creating components of parts. CNC routers are suitable in high-speed working on softer materials and will be used where speed and size of the material is more important than final accuracy.

By understanding such differences, manufacturers will be able to make right choices of the technology they wish to use in their production process so as to achieve high efficiency, high quality and cost effective production process.