Meta Description: Find out all the facts about plastic injection tooling and its associated mould tooling with reference to its materials, design factors, quality, cost considerations and cost reduction. Discover the secrets of tool selection, maintenance and other trends in global manufacturing with industry professionals.

The backbone of plastic manufacturing today is injection mould tooling and it forms the very foundation of manufacturing millions of high quality plastic components all over the industries. This resource book taps into the complex nature of injection mould tooling to cover basics of concepts through to highly technical aspects of engineering factors that make manufacturing workflow with high quality parts and materials as efficient as possible.

Understanding Injection Mould Tooling Fundamentals

Injection molding is a manufacturing process which shapes susceptible plastic material melts (or plastics) in a metal shape. The mold is commonly termed as tooling. In this, molten plastic is forced under high pressure into wrought molds to form intricate components of unrivaled dimensional accuracies as well as finish surface quality.

Tooling system does not only imply the mold itself, but also entire environment of parts, fixtures, and equipment used to support the successful production. Contemporary injection mould tooling combines the state of art engineering concepts with new advanced tooling material science to meet the targets of best performance, including high pressure injection life span, and economic viability of the manufacturing process.

Core Components of Injection Mould Tooling Systems

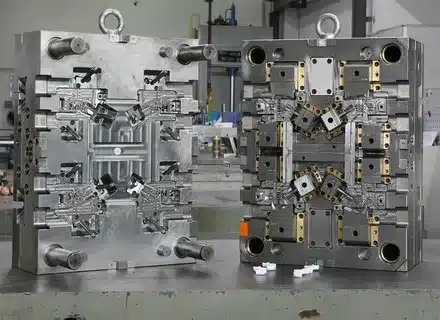

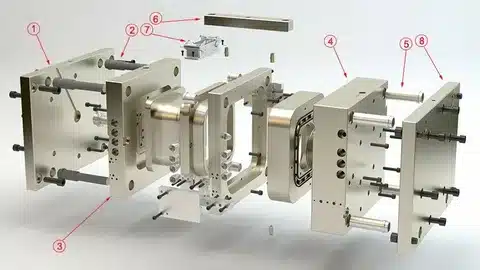

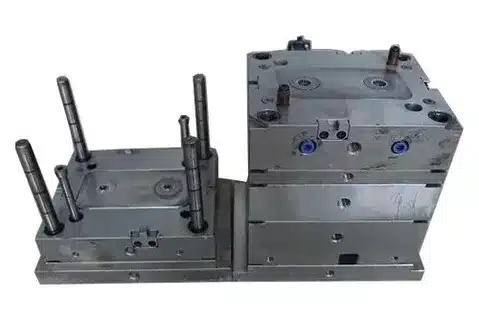

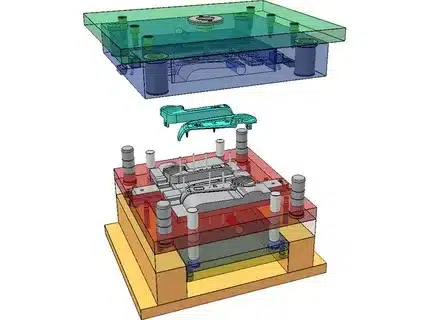

The injection mould tooling systems are made up of various interdependent parts which when combined serve to convert raw materials of plastic materials into completed products. Characteristic features are the central area and the mold cavity, which is the negative volume of the required piece, as well as other complex features, including multi cavity molds, ejection systems, cooling systems and gating systems.

Slides, guides, lifters, pins, bushings, ejectors and alignment devices may be part of the inside components mold. These top-level machined parts ought to operate in complete harmony so as to guarantee part quality reliability, effective cycle times, and long tool life through out manufacturing process.

Material Selection for Injection Mould Tooling

The choice of material is among the most significant in the design of injection mould tools and can have a direct influence on the performance of the tool as well as its lifetime and economic success as a whole in the manufacturing process. Injection molding tooling can be made from various tooling materials such as steel, aluminum or alloy. Both have specific benefits and disadvantages that should be taken into account carefully measured by the necessity of production needs and parts complexity, and economics.

Steel tooling is more durable, and heat resistant, which makes it most suitable in the high-volume production environments. Steel is able to withstand stronger pressure and more heat and still the mold is intact. Steel injection mold tooling can enable the production of hundreds of thousands, to millions of plastic parts. Aluminum tooling is faster to machine, less expensive initially and is generally suited to lower production. Aluminum tooling may also need more frequent maintenance.

Design Considerations for Optimal Performance

A well-designed injection mould tool not only needs to take into consideration many engineering factors that affect quality of parts, efficiency of production, and life of the tool. Tolerance is affected by tooling design, materials and by cavitation. Overall, easier is the process the better are the chances of tight tolerances to be achieved and maintained.

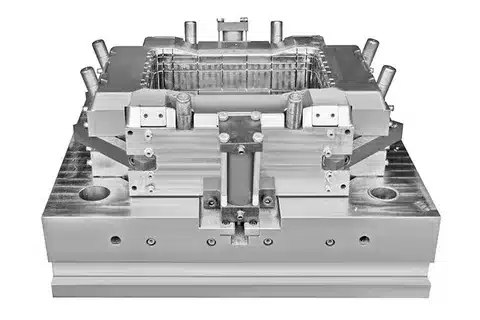

The geometry of the parts may be complex in nature and as a result, require highly sophisticated tooling solutions to be developed and included in the tooling designs; more advanced features may include multi-cavity and hot runner systems or special cooling techniques. Where geometries are complex, injection molding tooling may need rotary mechanical racks/gear, rotary hydraulic motors, hydraulic cylinders, floating plates, or multi-form slides to be added.

Quality Control and Precision Manufacturing

There is a need of great attention to detail and strict dimensional tolerances (tight tolerances) that are concerned with quality control in the manufacturing of the injection mould tooling. The latest tooling plants have technologically superior measurement, computerized machining center and highly complex inspection technology to make sure that each and every parts are produced according to the most highly scrutinized specifications.

To make high quality parts it takes high quality tooling. This is the guiding principle, which leads to the relentless journey to perfection in terms of tooling manufacturing practices, material science, and quality control practices. Inclusion of regular maintenance based on schedules, preventive care routines and overall inspection procedures ensure optimum tooling performance during long production runs.

Advanced Manufacturing Technologies

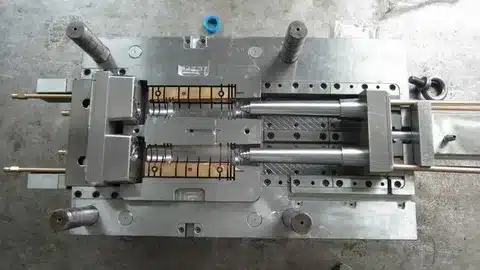

The modern injection mould tooling manufacturing uses top technologies in order to attain unmatched precision and efficiency. Electrical discharge machining (EDM) can be used to make steel mold tooling. EDM is extremely accurate and this gives our engineers the chance to develop tooling featuring extremely intricate geometry and very narrow tolerances impossible to fabricate using traditional techniques.

Computer-aided design (CAD) software, computer numerical control (CNC) machining, and additive manufacturing technologies allow tooling engineers to produce more and more complex geometries with the dimensional accuracy that is exceptional. The high-level manufacturing capabilities widen the scope of the design, and enhance the performance of tooling in general.

Cost Optimization Strategies

Prudent cost management of any injection mould tooling calls that the cost of the entire lifecycle must be fully understood and not just the cost in terms of investment in the tooling. A good injection molding tooling will be costly, but they will maintain good quality of parts and mold tooling with top of the line life span.

Other aspects that are strategically put into consideration are the choice of materials, cavity design, maintenance needs and anticipated production volumes. The more components that can be created using the mold tooling, the cheaper each piece is going to cost throughout the years cooling characteristics. The nature of this principle is to support the idea of building tooling systems that will be able to operate long-term production streams and keep the rates of quality at the same high level.

Maintenance and Longevity Considerations

Preserving and protecting injection mould tooling by following the right maintenance procedures, along with process optimization, is the key in stretching out or making the most out of the tools used in production and time. Cleaning, routine inspection, and maintenance processes, as well as repairs of worn out parts, prevent expensive production stoppages and ensure consistency of the quality provided by parts.

As compared to metal tooling, steel mold tooling is a lot easier to maintain, will not rust, gives a very good finish to each piece and is also easily changed by inexpensive welding efficient cooling. Developing complete maintenance schemes covering thorough documentation of tools, inventory of spare parts, and availability of trained workforce on maintenance guarantees maximum output of the tools in long production runs.

Cooling System Design and Optimization

Good cooling system design is a vital tool in injection mould tooling and it directly affects cycle time or part quality and efficiency of the overall production best shut off methods. Location of cooling lines and waterlines with the aim to maximize coolant distribution and minimize warping is the aspect of engineering significance that needs thorough analysis of heat transfer properties of the materials and demands of thermal management injection speed.

A sophisticated cooling approach can involve circuit conformal cooling channels as well as temperature control as well as special cooling circuit plans. Appropriate cooling system design and automated systems eliminate part defects like warping, sink marks or variation dimensions and allows quicker cycle time and greater productivity process repeatability.

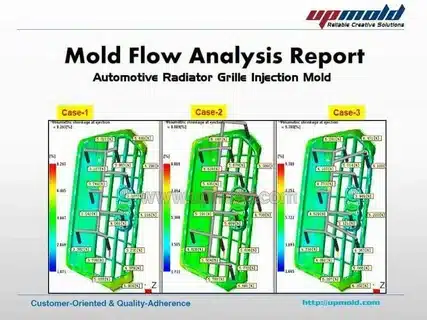

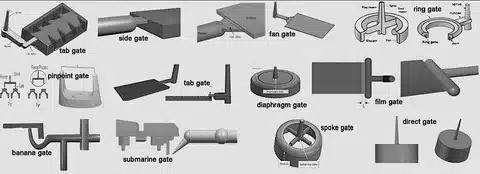

Gate Design and Flow Analysis

The way gates are designed and located have enormous impact on the quality of the parts, the fill patterns as well as the entire molding performance. Identification of the gate type and location to realise the best flow, fill pressure, cooling time and size/tolerance demand advanced studies of material flow path and pressure distribution over the body of the mold.

The new tooling design takes into consideration high-tech flow simulation software in optimization of location of the gates, size of runners, and filling patterns. This decreases cost and development time of tools by enabling prediction of the possible problems that may arise during tooling construction process in terms of weld lines, air traps, or not filling the tool completely with material properties.

Sensor Integration and Process Monitoring

Modern injection molding processes involving injection mould tooling with built-in advanced sensor systems is gaining prominence since this allows a real-time process status to be monitored and controlled. Transducers strategically located within multi-cavity and hot manifold tools to track and control the process in real-time are important in terms of gathering data that can be used in optimizing processing parameters and the part quality consistent quality.

Such monitoring systems are capable of monitoring key parameters like cavity pressure, temperature profiles, and the character of fill, which are vital in order to make an on the spot correction in case of deviations. Owning to the advanced sensor integration, predictive maintenance processes are facilitated and injection pressure is monitored, helping to avoid costly production ground-stops and high quality materials.

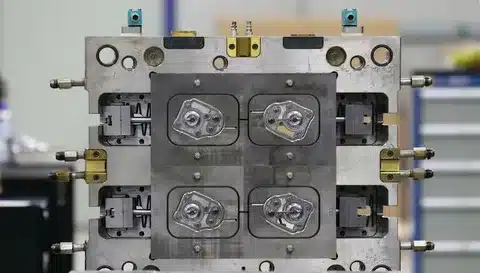

Multi-Cavity Tooling Considerations

Because of material flow balance, cooling uniformity, and dimensional uniformity challenges arising with multi-cavity tooling design, specific attention should be paid to the considerations of material flow balance, uniformity of cooling and dimensional uniformity covered by all the cavities. The engineers should strive to have equal pressure and rate of cooling in filling all the cavities in order to have consistent part quality on the production process.

Advanced design of runners systems, pressure drop and thermal analysis are used to maximize multi cavity performance. These factors are even more significant, when more cavities are involved and the parts become more complex to retrofit a high level of engineering expertise and fine manufacturing skills are necessary.

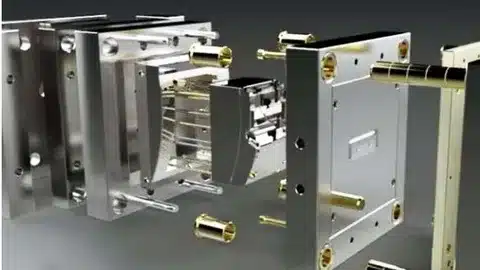

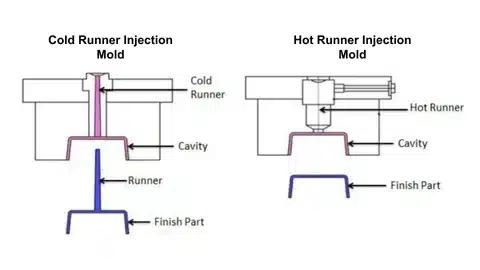

Hot Runner Systems and Temperature Control

Hot runner systems are a relatively new tooling system which can majorly enhance efficiency and material consumption of the production process surface finish. These systems continuously keep molten plastic at ideal processing temperatures inside the entire runner system, where there is no need to expel and recycle the runner material at the end of the usage and molded parts.

Hot runner systems necessitate the right thermal management so that no degradation of the material takes place and the flow characteristics become consistent. With modern hot runner systems there is a complex heating component, temperature controls, and a sophisticated temperature control that allows the whole system to be controlled thermally precisely without any movements.

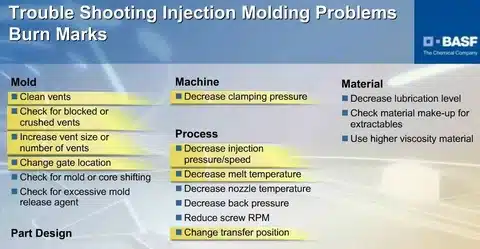

Troubleshooting Common Tooling Issues

Practical resolution of sophisticated tooling and injection mould tooling problems by means of getting to the bottom of the troubleshooting process, proper diagnosis of the causes and appropriate action plans aluminum molds. The wide spread problems related to common tooling are variation of dimension, defect surface, incompatible wear or ineffective filling patterns plastic injection molding.

Improper performance of parts hinges on the timely and successful resolution of these problems. Tooling engineers that have experience with the tools create extensive troubleshooting procedures facilitating the location of the sources of problems in a short period of time and executing successful remediation practices that lead to the normal performance of the tools OR tooling process.

Global Manufacturing and Supply Chain Considerations القولبة بالحقن

The industry of plastic injection tooling is a branch of a complicated international chain of supply including several continents and a great number of specialized suppliers mold components. International manufacturing skills, the best quality and logistics needs should be understood in order to properly buy tooling and manage global projects tooling durability.

Firms, such as Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide), assist in the global tooling campaigns as they offer important logistics services. A professional logistics service provider engaging in global freight forwarding, supply chain management and cross border E-commerce logistic production molds, GWT Worldwide provides a full range of products air freight, sea freight, China-Europe railway, international express, customs clearance, and warehousing molding machine. Their experience in effective transparent logistic will facilitate safe and compliant transportation of tooling components as well as finished molds across the manufacturing plants to final users all over the world pre hardened steel.

Emerging Technologies and Future Trends

With the new set of technologies, the injection mould tooling sector keeps growing, and will transform the manufacturing capabilities and performance attributes. Tooling designs and processes are changing because of additive manufacturing, advanced material science, artificial intelligence and Industry 4.0 technologies plastic resin.

Such technological progress provides more functionality with geometries that are more complex, their performance characteristics as well as the efficiency of their manufacture. Future technology in tooling advances is therefore expected to be centered on the integration of smart manufacturing systems more and the use of advanced materials including those of renewable manufacturing processes and practices prototype tooling.

Environmental Considerations and Sustainability

Environmental issues and green design concepts are entering the modern tooling design of injection moulds. This is in addition to using recyclable materials, energy saving processes in manufacturing and producing toolings that enhance production efficiency and produce less wastes in the process of manufacturing mass production.

The sustainable tooling is a lifecycle, which extends the starting point of the design to the option of end-of-life disposal, or recycling. These factors are gaining momentum as users want to minimize the environmental impact while ensuring wear resistance and still sustain high levels of performance of the manufacturers optimum flow.

الخاتمة

Injection mould tooling is a complex field of engineering incorporating materials science, precision engineering and innovative design to allow the manufacture of plastic component parts in a high quality. Tooling projects must be handled with total knowledge of the properties of materials used, tooling complexity design, manufacturing options and quality control procedures. Using technologies such as sophisticated technology control, sensor based systems, and using global supply chain mechanisms, tooling performance and efficiency has been improving and rising.