In the analytical, get-accurate-or-else world of modern manufacturing, the quality of the part’s surface roughness levels, as surface roughness measured, is not a cosmetic issue—it’s part of the process control, tool management and functionality of the part. In the milling area, there are many factors that will affect surface finish; this includes cutting speed, the geometry of the tool, material characteristics and the condition of the machine. The machinists always look for a better milling finish as it can have a direct impact on the wear, fitment accuracy, and in some cases, the product lifecycle.

Moreover, proper surface finish parameters can also eliminate the requirement of secondary operations such as grinding polishing and time as well as cost of production is saved. Smoother finish usually signifies stable cutting and the right engagement of tools, fundamental to ensure the dimensional uniformity throughout the production of several factors and parts. With the evolving manufacturing standards, there is a need for consistently producing high-quality surface finishes to achieve the desired surface finish by way of perfect milling practices – a statement of skill, more of necessity in business. Machinists that can make proper adjustments to all those factors influencing a given thing will have better tools for satisfying the complex requirements of contemporary environments of production.

Tool condition and machine stability role

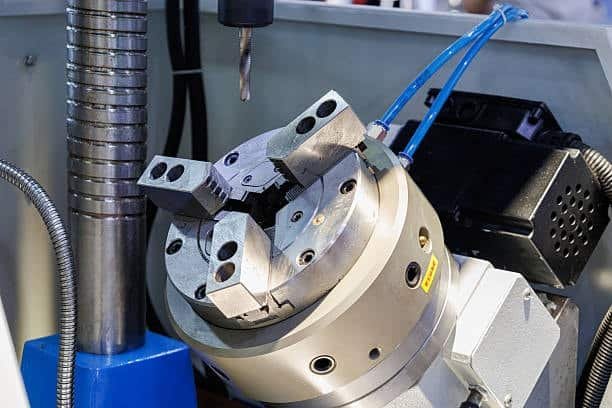

A critical, but at times underestimated aspect of milling surface finish is to find the cutting tool in fit-for-purpose condition to extend its tool life and the overall machine stability. Chatter, vibration and varied finishes can be caused by surface defects such as a worn or badly sharpened tool, which can interfere with the evaluation length and ultimately these lead to loss of integrity and aesthetic value of the resulting machined part. Machines that are not rigid or are under-calibrated can also induce slight deflections during the cutting processes, which form visible marks or irregular surfaces. Thus, the day to day repair and care of both tooling and machinery is crucial so they perform at their best and are able to guarantee predictable high results.

Apart from maintenance, Choice of suitable cutting parameters, along with key parameters such as feed rate, spindle speed, and depth of cut, is also very important. as far as optimizing surface finish is concerned with various manufacturing methods . Variables such as feed rate, spindle speed, and depth of cut need to be accommodated with care in accordance to the material being machined and the intended end result. Overaggressive cut can cause tool deflection or tearing of material, and too conservative setting can cause inefficient production and increase in tool wear, impacting the vertical distance between layers . Adjusting these parameters to the right fit of the machining context, operators can control surface roughness levels, increase the surface smoothness, and adapt to various manufacturing processes for a more effective. and less expensive manufacturing process.

The Effect of the Material Behavior on the Finish Quality

The characteristics of materials also play a great role on how a milling finish is concluded. Softer materials such as aluminum might be easier to cut but they can smear in case of improper cutting condition causing a rough or irregular surface. Stronger materials, however, necessitate strict feed rates and cutting speeds control to avoid the wear of the tool and provide a good finish. Comprehension of the behavior of diverse metals and alloys under particular milling conditions, as indicated in the surface finish chart enables machinists to adjust their machining skills to suit the situation. When the parameters of selecting tools, cutting parameters and responses of materials are congruent, and to measure average surface roughness accurately the machinists are able to produce consistent precise surfaces that meet the desired specifications and are aesthetically and functionally appropriate.

In addition, coatings and tool materials, including powder coating, need to be well matched to the workpiece to allow for further improvement in the surface profile quality through techniques like bead blasting . of the surface and increase the life of the tool. For instance, coated carbide tools may be perfect for cutting hard alloys due to better wear resistance against heat and lesser friction, which directly translates into smoother surfaces. Conversely, a somewhat coated tool may suffice for softer metal used in the right conditions to enhance its visual appearance. Additionally, the coolant or lubrication used during the milling process can also influence the surface finish. When properly applied, heat accumulation is minimized and carbon chips are washed away, hence lowering tool wear and surface imperfections. This knowledge of technicalities allows the machinists to perfect all details in the milling process, and produce parts of ultimate precision, quality and grade.

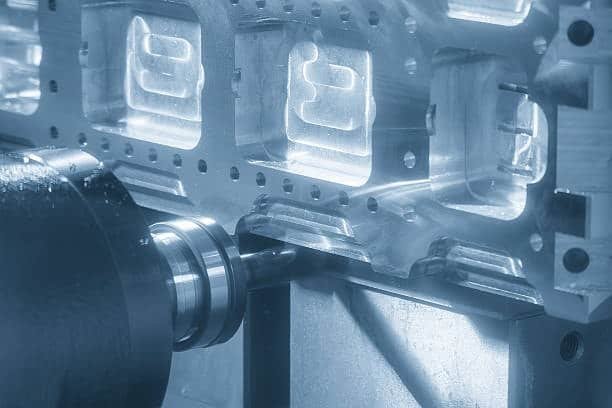

Defining Milling Finish in Practical Terms

A milling finish refers to surface texture that remains on a work piece after a milling activity is undertaken. This texture, which can be measured with the help of parameters such as Ra (roughness average) and average values to gauge texture, including surface roughness measured, center line average, Rz, the mean line or the surface waviness., as outlined in the ra surface finish chart indicates the influence of the cutting tool on the material in terms of average maximum height in the end product.. A uniform finish should imply to an ideal cutting situation, a conspicuous tool mark, chatter or pitting implies mechanical inefficiency or wrong techniques in machining.

Surface finish quality is not arbitrary when working in industries: it is often specified by engineering requirements based on functional requirements. For example, a sealing surface of a hydraulic component may need especially fine surface texture if leakage is to be prevented while the structural componenets may allow for rougher surface texture if the cosmetic appearance is of no consequence to the value of the parts. As a result, customizing the machining process to get the desired mirror finish for the product surface of cnc machined parts is an art and science. is an art and science.

Measurement, and Evaluation of Surface Finish

In order for surface finishes to be guaranteed to match the industry requirements, the machinists use very accurate instruments like profilometers, optical scanners, and diamond stylus to help measure surface roughness accurately. Ra (average roughness) can provide an overview of texture; whereas Rz (mean peak-to-valley height) and Rt (total height of the roughness profile) can provide more specific information on the surface change. These surface finish measurement techniques assist in validating the adherence to design specifications and also determining whether readjustment in the tooling, feed rates, or the spindle speed needs to be made. Consistent monitoring and recording of the surface finish does not only guarantee quality of products but also contributes to consistent results among batches in large production.

Besides evaluation, interpretations of the machining surface finish data can help machinists identify underlying problems in the process of milling and adopt appropriate remedial measures. For instance, an increment in roughness on the surface could mean tool dulling, wrong coolant flow, or high vibration may lead to rough surfaces . By recognizing such patterns early, corrective measures can be taken before defect sees itself spread to a whole batch. This forward-thinking approach does not only make products better but also enables the use of a surface roughness chart, cutting down waste, stoppage, and rework costs. In high precision industries, the art of reading surface finish data like a diagnostic aid becomes the critical focal point for operational excellence and meeting the demanding customers’ expectations.

Finding the balance between aesthetics and functions

In some of the industries, for example in aerospace, medical devices and automotive manufacturing industry, the root mean square average of surface finish of a manufactured component has both functional as well as aesthetic implication. A luxury consumer product may need a perfect finish for aesthetics purposes, and a medical implant needs to have near-immaculate average roughness surface tolerances lest it induce tissue irritation or bacterial adhesion. This duality requires machinists to strike a balance – meet the average maximum height performance criteria while producing cnc machined parts suitable for different manufacturing processes that meet the visual expectations. Preeminent acquisition of this balance hinges on experience and technical comprehension coupled with the knack of tuning processes while at it, which validation makes milling finish a complex aspect of modern manufacturing.

Understanding how surface finish affect the total functionality and longevity of the product is furthermore necessary to achieve such balance between surface finish and roughness grade numbers is necessary . For instance, in the case of aerospace industry, a sleek finish can reduce drag and thus enhance fuel economy whereas for the medical industry a smoothing surface will be necessary for biocompatibility with implants. While the requirements for improved precision requirements increase, machinists should also consider sampling lengths, and are no longer required to simply be experts at surface finish techniques but they also need to be experts at predicting the predominant surface pattern will influence long-term impacts of different finishes on the functionality of products. This greater knowledge of the way in which milling tends to affect both immediate quality and subsequent performance raises milling finish from technical competency to one of the key constituents of strategic product development.

Influencing Factors That Shape Milling Finish

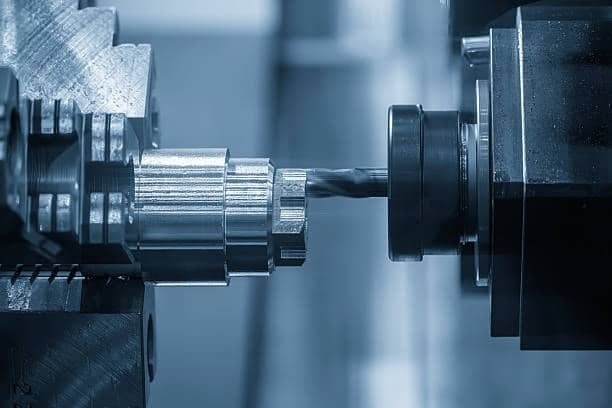

There are several interdependent factors that guide the resulting finish in a milling operation. The most important include tool geometry, including rake angle, nose radius, and helix angle as indicated in the machining surface finish chart . A greater radius of the nose usually gives a smoother finish because it leaves less height of scallops between successive cut-throughs, making it easier to measure with a stylus tip . Equally, sharp tool with positive rake disposition routinely shears materials more cleanly as this helps to reduce uneven surfaces.

Cutting speed and feed rate are vital for reasons as well. Higher cutting speeds are more likely to lead to better finishes of the surface if combined with appropriate feed rates as it reduces the build up on the cutting edge as well as reducing vibration. However, aggressive feeds and excessive low speeds may result in rough torn surfaces, which negatively impacts the overall surface finish, especially on ductile metals., affecting the vertical distance, such as in aluminum or brass. Moreover, depth of cut and step over distance are to be carefully controlled in order to have a regular tool engagement considering the corner radius and to avoid the presence of surface ridges.

The final product is also influenced by machine condition and rigidity of the spindle. Worn bearings, backlash in the axes, and poor damping may lead to chatter marks and tool deflection rendering a surface inconsistent. High-performance CNC machines with close tolerances, often utilizing a face mill, are usually used in cases where finish quality is valued above everything else.

Material Characteristics and Their Impact

All materials do not give yield to milling forces, alike. Metal materials that seem softer (like aluminum or copper) may be rough to cut due to smearing or built up edge which can ruin surface smoothness. On the other hand, materials that are harder such as stainless steel or titanium require stiffer tooling that can also resist wear and a more accurate speed control in cnc machining., order to prevent premature wear or burning of the surface.

Presences of inclusions, different grain structures, or a hardening tendencies within the material may influence finish uniformity as well. Hence, machinists quite often custom their tool coating-supplies (such as TiAlN, or DLC and especial coolants or lubrication techniques) to methods like laser triangulation can improve finish quality as well as minimize friction when milling.

Techniques to Enhance Milling Finish

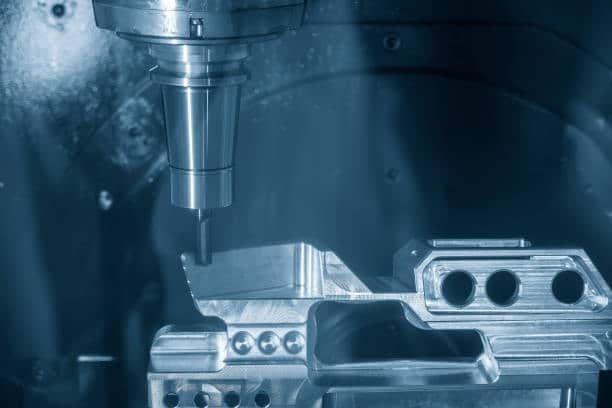

There are a number of practical solutions which can be used to improve milling finish; in many cases, the solution would be to combine tool optimisation and There are a number of practical solutions which can be used to improve milling finish; in many cases, the solution would be to combine tool optimisation and the There are a number of practical solutions which can be used to improve milling finish; in many cases, the solution would be to combine tool optimisation and the machining process parameters for better efficiency…. Climb milling, for instance, is likely to produce better finishes than conventional milling because of cleaner shearing action and minimized contact of the tool with the surface to be milled. Similarly, finishing passes with a smaller radial step-over decrease the amount of scallop height and the finish becomes smoother.

Using high-accurate carbide end mills with smooth flutes or specific coatings can make more sense in terms of surface quality. Where necessary, multi-axis finishing passes, as performed in 5-axis CNC machining, using round inserts can match the tool path with the contour of the product surface., minimizing the marks of the tool and the creation of smooth surfaces ensures that uniformity of the finish in the machining process is critical. for achieving high standards .

At times post-processing methods like polishing, buffing, or even laser surface texturing may be employed to satisfy the surface demanding for specific functions. However, the thing you cannot lose is the best possible finish from the milling operation in combination with bead blasting as the achievable surface roughness i s the issue of cost and time efficiently the best strategy in large scale production facilities.

The Relationship Between Surface Finish and Functionality

Apart from a pretty sight, the quality of a milling finish actually impacts performance and longevity of machined parts. The fine finish minimizes the degree of friction, Apart from a pretty sight, the quality of a milling finish actually impacts performance and longevity of machined parts, enhancing relative smoothness. which is necessary in MOVING parts or friction surfaces. It also reduces stress concentrations that may cause fatigue cracks or corrosion in the long-term. A good adhesion and functional soundness are attained in components whose surface finish qualifies for the sealing or coating requirements.

Surface finish in precision engineering is also important for purposes of dimensional accuracy, especially where there is a need to measure surface roughness for minimal clearance between parts. Less than satisfactory finishes can inject measurement variations or obstruct anticipated assembly tolances. Surface finish, therefore, is not an afterthought—it is inherent to the quality of product and to functional success.

الخاتمة

The high-quality milling finish is an involved process that requires not only technical capabilities, but also the savoir-fair on machining dynamics. No matter if a workplace is dealing with delicate aluminum parts or hard-to-machine alloys, the target is identical: in order to achieve best results in a surface with minimal secondary processing. göstering tecnology, expectations for tolerance will tighten, but the ability to work with the science of surface finish will continue to be a key skill in the new reality of modern manufacturing.

With the advancement of industries towards tighter tolerances and complex geometries, surface finish will only continuously become important. Some of the emerging technologies; such as high speed machining, multi axis CNC systems, adaptive control software are transforming the management and optimization of surface quality. As much as sophisticated tools are used, they still depend on the individual involved (the machinist) in terms of knowledge and intuition to make quick-time decisions that machines cannot handle alone. In this emerging world, synergy among human expertise and state-of-the-art technology will be the yardstick for the new standards of milling finish for those who use the machines and those who understand the art.