Meta Description: Learn about the Swiss machining technology, applications, and advantages, including the efficiency of the cnc lathe . Find out how this form of precision manufacturing is transforming industries that need very tight tolerances and manufacturing of complex parts.

Switzerland machining is the definition of the most accurate manufacturing process and the fabrication of small-scale or complex parts at the highest possible accuracy across different sectors, particularly with swiss cnc lathes . Swiss machining is a metal cutting game plan that was introduced in Switzerland whereby, small and intricate parts are machine-made with a lot of accuracy with the use of the lathe. It was invented at the end of the 19 th century so as to create the miniature parts in the mechanical watches. This groundbreaking manufacturing process is still developing; modern products have made it advanced and combine recent developments in automation and artificial intelligence in order to cope with the high demands of contemporary production.

With more complexity in the global supply chains, manufacturers need to rely on quality logistics partners to deliver precision-machined parts, including various types of precise parts, safely and efficiently. GWT Worldwide is a professional logistics solution provider of global freight forwarding service and supply chain service, and provides computers, electronics, industrial equipment, precision manufacturing company, and other enterprises in the world with unified shipping service including air freight, sea freight, China-Europe railway transport, special support of Amazon FBA Shipping.

What is Swiss Machining and How Does It Work?

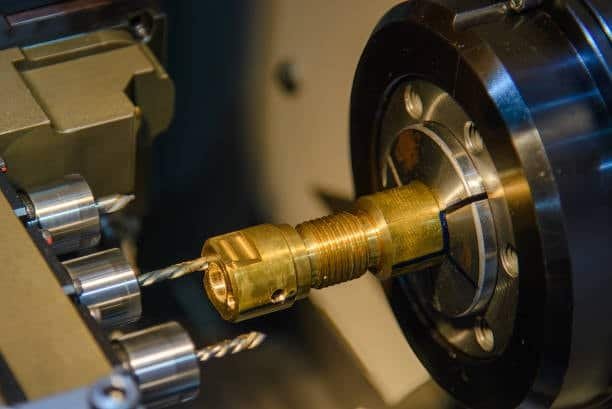

A Swiss type lathe (or Swiss automatic lathe) (officially referred to as a Swiss CNC machine) is a modern precision machine tool capable of locking onto small parts very quickly and precisely, utilizing swiss turning techniques . The operation of the Swiss machine is that it takes bar stock into a guide bushing which holds the work firmly during the machining operation. This is a distinct design concept that makes Swiss machining different to the common turning processes.

The basic distinction is the guide bushing system which maintains the workpiece in close contact to the tool cutting instrumental against exact deflection and severe vibration. Unlike conventional lathes where the component protrudes out of the chuck parts, Swiss machines feed the materials through a stationary guide bushing and the cutting tools act on the supported materials. This kind of set-up allows manufacturing of very tolerant parts, of the most exact ones, making tight tolerances difficult parts work with long and thin pieces, when using this configuration, the part could only be machine with high tolerances to almost impossible using mainstream techniques.

It starts by placing the bar stock material through the headstock and guide bushing. As the material moves it rotates against several cutting tools, utilizing multiple operations that execute several tasks together such as turning, drilling, milling, and threading. The whole thing is computer assisted so the parts coming out will be standardized and can be of large production scale and the quality of surface finish will be absolutely good.

The Rich History and Evolution of Swiss Machining Technology

The watch making industry required very minute and precise components and consequently introduced the Swiss machining technology. The first Swiss automatic lathes were mechanical wonders, greatly influenced by the swiss watchmaker jakob schweizer, with the purpose of making watch parts with a precision and repeatability other than ever before. These early machines founded the Swiss reputation of precision engineering, and gave way to the modern CNC Swiss technology.

This replacement of mechanical systems by computer controlled systems signaled a great development in the performances of Swiss machining. These modern versions of CNC Swiss machines give up the original concept of guide bushing to apply advanced technologies such as live tooling, sub-spindles, as well as multi-axes technology. 2024 offered tremendous development in automation and artificial intelligence (AI) in CNC Swiss machining. State of the art AI algorithms are currently used to complement machine learning features to be more intelligent by getting better predictive maintainers, machining processes, and quality hardware.

This evolution in technology has seen an enormous increase in the machining applications by the Swiss, particularly in the production of aerospace parts, and it is impossible to rule them out in the aerospace, medical device fabrication, electronics, automotive and telecommunications sectors. The overall evolution of Swiss machining guarantees that it would not be rendered obsolete in an ever more complex manufacturing environment.

Key Advantages and Benefits of Swiss Machining

Swiss CNC machining presents not just features but lots of benefits, so it is the first to choose when you desire high-precision manufacturing: Extreme Precision -A maximal level of precision as well as repeatability is accomplished, and that makes it great to use when dealing with parts that are mission-essential. Reduced Cycle Times – Since Swiss machines complete several operations during a single set up, their working time is tremendously shortened. Reduced Secondary Operations A good percentage of the parts are taken off the machine in some causal conditions; they are completely completed-no deburring, grinding, or polishing.

Switzerland machining precision abilities are of a very high standard. CNC Swiss lathes have tolerances down to microns, and so components to a very tight specification can be machined. The desired fit and functionality of even the smallest components is done through this accuracy. This degree of precision is important in the industry where a slight variance may lead to failure of the product, or safety issues.

Swiss machining is a cost effective alternative to traditional metal processing because it allows one to perform several machining jobs in a single set up. This decreases the cycle times, labor and raw materials thus saving the manufacturers big bucks. It also has efficiency and accuracy which leads to increased throughput and lower scrap rate. The fact that a complex part can be made in one go, eliminates the number of setups, hence the amount of time it will be taken to handle such a thing besides the personal errors that can be avoided hence making it more productive.

Swiss machining is very repeatable and is well suited to the high volume production runs in which all parts have to be to exacting specification. Such consistency means that the manufacturers will be in a position to uphold quality and deliver to tight schedules.

Industries and Applications for Swiss Machining

Swiss precision machining has acquired fame due to its capability to manufacture high precision and repeatability parts. It is contingent on this and is therefore suited in industries that needs precision parts like medical and aerospace industries. Medical device industry sector especially advances both the production of complex geometry biocompatible components and very tight tolerances of which Swiss machining excels.

Swiss machining in the aerospace industry is used to manufacture such critical parts as the fuel system components, hydraulic fittings and electronic connectors where the key issue is precision and reliability. Swiss machining is of great use in the automotive industry, specifically in the manufacture of the fuel injection components, transmission parts and electronic sensor housings which need a very high accuracy and quality finish of surfaces.

Machining to form connector pins, threaded fasteners, and miniatures that are used in smartphones, computers, and communicating devices relies heavily on Swiss machining in the electronics industry. It is also highly accurate hence very popular among manufacturers of auto parts. Making and customizing parts that conform to the standard requirements, including surgical screws, is an industry using machining processes.

The telecommunication, defense, and energy industries also have a side of the coin as far as the precision machining of specialized parts which should work reliably in harsh conditions. Swiss machines are versatile; hence the manufacturers are able to adjust to a changing industry requirement with ease hence without reducing the quality.

Swiss Machining vs Traditional Machining Methods

The biggest difference in the Swiss and the conventional machining process is workpiece support and cutting method. Traditional lathes have parts attached to a chuck, with the workpiece protruding: longer and thinner parts may deflect and vibrate as a result. Swiss machines remove this constraint as we allow the workpiece near the cutting area with the help of guidance bushing system.

Faster Machining Swiss machining has the ability to micro-machine the small components along the longitudinal axis that are smaller, stronger, and lightweight with high quality. All this sums up to the fact that the Swiss machines can carry out more complicated machining activities than any other form of CNC machining system. The capability advantage is especially noticeable when the length-to-diameter ratio of the parts being machined is high i.e. would not be possible or difficult to do using traditional techniques.

Complex parts made by traditional machining may need many setups and several operations to finish the machining process, volume their production and waste extra handling and a possible error. Machines made in Switzerland have the ability to turn, mill, drill and thread in rapid sequence, which means reduced cycle time by orders of magnitude which increases accuracy because setting up variations no longer occur.

The quality of surface finish is usually high in Swiss machining since of the hard support of the workpiece and favorable cutting conditions. Guide bushing system reduces vibration and chatter leading to smoother surfaces that do not always demand second finishing procedures.

Materials and Specifications in Swiss Machining

Swiss machines have been the leader in machining most types of materials including carbon steel, such as stainless steel, aluminum, brass, titanium, inconel and many exotic alloys. The guide bushing system offers the stable cutting conditions necessary to utilize aggressive cutting parameters even in challenging-to-machine material improving both productivity and surface-quality.

Swiss Material considerations also come into play with regard to diameter limitation of the bar stock which should be between 1mm to 32mm, depending with the capability of the machine. The bar fed mechanism needs straight and consistent metal stock with little to no run out so that it has good machining capability. The properties of materials and heat treatment needs have to be taken into consideration carefully to choose cutting parameters and cutting tool geometry.

Dimensional tolerances that can be attained by using Swiss machining are incredible with a common tolerance of +/- 0.0002″ to 0.001″ in most geometries of the parts and materials. The surface finish-capabilities reached Ra values as low as 16 microinches in some cases, thus eliminating secondary polishing operations in most all of the applications.

This versatility of geometries available in Swiss machining is accounted by the deep holes, thin walls, sophisticate threading, and the multiple features that a single manufacturing process can be performed over. Cross-drilling, milling flats, and complex sub-divided contours that would take several workstations in non-Live tools are possible using live tooling abilities.

Advanced Features and Technology in Modern Swiss Machines

By 2024, energy-efficient machining recognition and sustainable operations in CNC Swiss machining shops will increase, and more environmental friendly manufacturing will be practised. This transition makes the industry more sustainable and greener in future. The modern Swiss machines have been designed with special features that promote productivity and minimal effect on the environment.

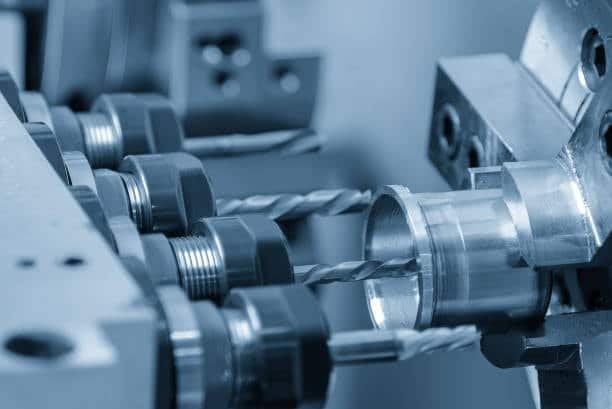

Multi-spindle patterns can machine more than one part at a time and so offer throughput over high-volume machining applications rapidly. The sub-spindle systems can help in the 100 percent finishing of the parts through secondary operations as the primary operations are still carried on in the main spindle.

Swiss machines added live tooling features turn the machines into a complete machining center, allowing cross-drilling, milling and complex contouring. Provision of y-Axis operation permits machining off-centerline operations, greatly increasing the breadth of part complexity achievable.

Sophisticated control systems incorporate artificial intelligence in line with predictive maintenance, automatic variations of the cutting parameters according to on-the-fly feedback, and tool life optimisation. Such smart capabilities minimize a production stop and enhance the quality and cleanliness of parts between production runs.

Quality Control and Precision Standards

Swiss machining places emphasis in the process of quality control; the process starts with accurate set up process, and proceeds to the in-process measurement systems. The latest Swiss machines have probing systems that actually checks the dimensions of parts being machined for security availability, unlike other machines, and their parts are automatically adjusted to ensure narrow tolerances within successive production runs.

Statistical process control (SPC) systems monitor dimensions, surface finish measurements, and grooves of the tools and shows trends prior to part quality impacted. This active way reduces the wastage levels and produces consistent output quality which satisfy or even surpasses expectations of customers.

Quality management systems such as certification to ISO 9001, AS9100 in the aerospace industry, and ISO 13485 in the medical equipment industries demand in-depth quality management systems that the Swiss machining operations should have in place. The latest software systems have been incorporated to allow seamless traceability requirement and documentation in current manufacturing processes in Switzerland.

These measurement and inspection capabilities comprise the use of coordinate measuring machines (CMM), optical comparators, and automated inspection system to check the complexes as well as surface qualities. Such quality assurance processes help in making sure that all the components are of high standards and meet the industry requirements and customer necessities.

Future Trends and Innovations in Swiss Machining

Industry 4.0 refers to technology in the production processes that entail the incorporation of connectivity, automatization, and artificial intelligence in the Swiss machining industry. The use of networked Swiss machines in smart factories enables them to chat with the enterprise resource planning (ERP) systems and automatically sequence the production and optimize the move of material.

Additive manufacturing integration is a new trend in which involves inclusion of 3D printing technology as an added provision of the capabilities of the traditional Swiss machining. The combination of additive and subtractive processes in hybrid machines allows creating complex geometries internally, whereby without such combination, it would be impossible to create the same functions using usual methods.

Sustainable manufacturing processes are leading to the innovation of new technologies such as management of cutting fluids, energy consumption, and wastes. Upgraded coolants as well as dry machining, decreases the effects on the environment, without compromising part quality or tool life.

Improvement in automation is seen in the form of robotic part handling systems, automated tool changing and lights out manufacturing processes that allow factories to keep producing with little or no human interaction. The developments ease labor shortage and enhance productivity and uniformity in Swiss machining processes.

الخاتمة

Swiss machining is an excellently developed precision manufacturing technology that can never be matched in terms of accuracy and efficiency in the manufacture of complex components. The technology originated in Swiss watchmaking and is still a must in such industries as aerospace and automobile industries that need manufacturing with a high level of precision.