Meta Description: Find out all about the material removal rate formula and metal removal rate (MRR) in machining. Find formulas, calculations, methods of optimization, including roughing and influences on the rates of material removal to have a more efficient way of manufacturing.

Among the most important indicators in the contemporary production and machining operations, the material removal rate (MRR) should be highlighted. Appreciating this basic principle can make the difference between your production efficiency, cost-effectiveness and profitability, tremendously. You may be running a small machine shop or a big manufacturing plant but your intelligence on the metal removal rates will give you an upper hand in the current industrial environment because of the intense nature of industry nowadays.

Understanding the Basics of Metal Removal Rate

Metal removal rate, also known as MRR is used to indicate the amount of material removed in one minute when a machining activity is performed. Owing to this basic measurement, the efficiency at which cutting activities are conducted is given firsthand and the measurement can help to calculate mrr, giving insight of productivity levels in manufacturing activities being carried out invaluably.

The actual concept goes beyond mere measuring, allowing itself to be used as a holistic measure of performance that depicts the efficiency of the cutting parameters, choice of tool and general approach to the machining. Units of Material Removal Rate normally include Time and a cubic (e.g. cubic inches per minute or cubic centimeters per minute).

Why Metal Removal Rate Matters in Manufacturing

Metal removal rate plays numerous significant roles in optimizing roughing and material removal rates in manufacturing industries. First, it gives a measurable approach of evaluating various machining strategies and the comparative effectiveness. Second, it can allow manufacturers to see how they improve with time as they invest in better equipment, cutting tools and optimization methods.

When analysing MRR, it is even more important to note that it is directly drawn to profitability. The faster the material is removed per unit time , the cycle times are decreased, the throughput is advanced, and the depth of cut is optimally enhanced as expensive machining equipments are utilised. This correlation sends the issue of MRR optimization, which can save money, and potential tool failure to the top agenda list of manufacturers who are interested in sustaining their competitive benefits.

The Science Behind Material Removal in Machining

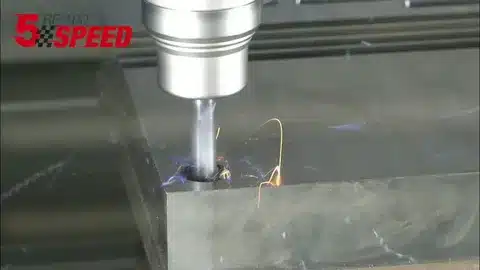

Physics of material removal is unlike the physics of material forming and the interactions between cutting tools, work piece materials and process parameters are much more complex. When a work piece is being machined, the cutting tools break through the materials which consist of the work to a certain depth and at a particular velocity forming chips, which carry volumes of the removed materials.

This knowledge of these underlying interactions will assist us in understanding the reason as to why some parameter combinations give better performances. Cutting forces, tool geometry and property of the material interact directly in determining removal rates in terms of what is achievable in terms of acceptable surface finish and tool life.

Essential Components of MRR Calculations

Metal removal rates are calculated based on various parameters of a cutting operation and a complication of several important variables, which allow coming to the end result. These parts are slightly different depending upon what machining process is being undertaken, including the grinding operation however, some of the basic elements are the same regardless of the machining process.

The major variables are depth of cut, cut width, and feed rate. All of the parameters have a different role in deciding the total amount of material that was removed at a time. The progress of these variables in appropriate measurement and optimization is the core of efficient MRR management.

Material Removal Rate Formula for Milling Operations

In milling, the material removal rate formula is defined, where depth of cut (D) in millimeters, the width of cut (W) in millimeters, and the feed rate (F) in mm/min is used as a rate of material removal given as MRR = (D x W x F / 1000) cc/min. This simple formula has direct information on cutting efficiency.

The Cutting parameter multiplicative relationship is portrayed by the milling MRR formula. Proportionate increase in any one distinct parameter proportionately enhances material removal rate, but parameter choices are limited by practicality of material being removed, choice of tool, power of associated machine and finish demands of surface.

Understanding Turning Operations MRR Formula

A special formula is used to convert turning operations and this is: MRR = D x F x S cc/min where D is the depth of cut in mm, F is the feed rate in mm/rev and S is the speed of cutting in m/min. This formula symbolizes the rotational aspect of the process of turning because it is a process that involves the incessant interaction of both the tool and the raw material workpiece.

In the turning formula, the speed of the cutting process is of high priority, and it is directly proportional to the rate of the spindle speed and work diameter. Knowledge of this relationship can be used in optimising turning processes to give optimum material removal on acceptable tool life and surface finish.

Key Factors Affecting Metal Removal Rates

The actual cutting parameters are not the only variables that determine the possible metal removal rate. The nature of the workpiece material also has a significant influence on the behavior of cutting and in general, harder materials normally demand lower cutting parameters so as to preserve the tool life and the surface finish of the cu

Geometry of tools, including axial depth and coating technologies, are also an important part in MRR optimization. The effectiveness of advanced designs of cutting tools to hold high cutting parameters without compromising performance directly translates in increasing material removal rate. The possible upper limits on attainable removal rates are set by machine tool capabilities, such as spindle power, machine rigidity and the degree of sophistication of the machine control system.

Optimizing Cutting Parameters for Maximum MRR

The process of optimization of material removal rates is aimed at ensuring a compromise among many parameters and some constraints as well, including tool life, surface finish to be obtained, and the available machine. Efficient optimization must be systematic in a way that all the variables involved must be taken into account as they interact.

Using achievable parameters and conservative cutting conditions and then slowly adjusting the conditions with successive round of observation of tool wear and quality on the surface is a viable optimization technique. More recent machining centers came with or adjustable control which makes the use of cut variables automatic and deals with changes automatically within the machining process.

Tool Selection’s Impact on Material Removal

Tool type has a huge impact on the rate of material removal that can be achieved in several ways, including the diameter of the tool used . Tool geometries and machining parameters such as rake angle, relief angle and edge geometry impact straight away on the cutting forces, chip formation patterns.

The material and coating of advanced tools allow the use of increased cutting speeds and feeds without compromising the tool life to an unacceptable level. Special coatings on carbide tools allow them to work under much higher parameters than regular high-speed steel tools, and as such, the removal rates have a significantly higher result.

Machine Tool Considerations for MRR Optimization

Tool type has a huge impact on the rate of material removal that can be achieved in several ways. Tool geometries and machining parameters such as rake angle, relief angle and edge geometry impact straight away on the cutting forces, chip formation patterns.

The material and coating of advanced tools allow the use of increased cutting speeds and feeds without compromising the tool life to an unacceptable level. Special coatings on carbide tools allow them to work under much higher parameters than regular high-speed steel tools, and as such, the removal rates have a significantly higher result.

Measuring and Monitoring Metal Removal Rates

Laser-sensing provides the correct assessment and constant tracking of material removal rates, which allows making optimization decisions on the basis of data. Historical measures of calculation of the amount of money usage based on historical calculations give the system baselines estimates, whereas the real-time monitoring systems provide better analysis regarding the actual performance.

In advanced production cases it is possible to monitor the real material removal progress and therefore measure where parameters can be optimised and where wear or other conditions known to compromise cutting efficiency exist. Such real-time feedback can be used in proactive adjustment or correction in order to ensure optimal levels of performance is maintained.

Common Challenges in MRR Optimization

There are a number of difficulties which are usually encountered in the process of optimizing the metal removal rate. When higher cutting optimisations are used, the volume of material removed and ool life can be seen as a trade-off, and this could be at the expense of productivity control. Many times, element balance is hard and raises removal rates with an agreeable tool life, there is a need to look at total cost on a part rather than the maximum cut speed radial depth.

Damage of surface finish in high cutting parameters might require after finishing processes, which negate the overall efficiency. Conceptualisation of such trade-offs can be used to make decisions about the best operating parameters concerning different applications.

Advanced Strategies for Increasing Material Removal

In addition to basic optimization of parameters, the process of optimizing material removal rates can be further optimized and thus be elevated. Techniques like the trochoidal milling provides the ability to remove materials at higher rates by scaling of cutting forces making it possible and providing a better evacuation of the chips.

Better cutting strategies are required to enable optimal removal rates to be maintained throughout complex operations. Adaptive strategies which include adaptive machining strategies that automatically change the cutting parameters based on the real time conditions are possible. These mechanisms react to changes of geometry, material and wear on the work pieces to remain at maximum efficiency how much material.

Industry Applications and Case Studies

It depends on the needs of different industries; a typical example is the level of material removal rate optimization given attention to. The manufacturing of aerosol parts may be highly concerned about surface finish and dimensional perfection rather than maximum removal rates whereas an automotive part can be concerned with cycle time reduction and achieving the ideal feed rate entailing very aggressive cutting parameters.

The knowledge of industry-specific requirements can be used in defining optimization strategies that can match manufacturing goals. The most effective MRR optimization initiatives take into account short-term increases in productivity as well as the long-term prospects of quality and cost.

Technology Integration in MRR Management

Digital technology is becoming a part of modern manufacturing surroundings in order to improve control of material removal rates. By means of Internet of Things (IoT) sensors, the cutting conditions could be monitored constantly, and the parameters could be automatically adjusted to ensure the best performance.

Machine learning algorithms can be used to automatically train to improve cutting conditions using historical cutting data and thus make prediction of optimal settings on new applications faster and with a reduction in setup time by doing optimization on parameters. These technologies symbolize the future of the intelligent manufacturing systems in which the process of automatic optimal rates of material removal will be provided.

Economic Impact of MRR Optimization

The economic value of the optimization of material removal rate stretches across manufacturing processes. Shortened cycle time is a direct correlation of more output without incurring more capital costs in the form of machinery.

When effectively optimized, low-cost per part is achieved because of enhanced efficiency and less usage of tools. The cost savings may help in gaining substantial competitive prices within price-sensitive markets as well as enhancing the general profitability.

Quality Considerations in High MRR Operations

It is important to balance between contrary goals to maintain the exercise of acceptable levels of quality and to maximize the removal rates of materials. Increasing cutting parameters may create problems like more tool wear, more cutting temperatures and even surface finish drawback.

The application of quality control strategies eliminates the possibility of quality products being produced at the significantly increased rates. Quality problems can be identified early by advanced process monitoring and hence Corrective action can be taken before production of bad parts.

Future Trends in Material Removal Technology

New technologies keep on expanding the limits of what it is possible to remove. Cutting tool materials and coatings advanced allow greater cutting speeds without loss of tool life. Better in-feed and more rigidity of machine tools due to improvements in design to allow cutting aggressively.

The use of artificial intelligence and machine learning can revolutionize MRR optimization, since, they automatically determine the optimum cutting parameters and make predictions on the tool behavior. These trends will make the study of accurate essential principles of MRR even more significant.

Best Practices for MRR Implementation

To have a successful implementation of the material removal rate optimization a systematic procedure that takes into consideration every factor has to be used. Beginning with optimal knowledge of working materials and tool capacities as well as limitations in the machine serves as initial basis in efficient efforts of optimization.

The implementation of regular checks and constant efforts to improve every detail makes sure that timely benefits of optimization are not wasted. The long-term success when using optimization programs can be supported by training the personnel on MRR principles, and equipping them with proper tools that can be used for measurement and analysis.

الخاتمة

Metal removal rate is one of the inherent measures that has a direct indicator influence on the manufacturing efficiency, productivity, and profitability. Learning the concepts from this article , equations, and optimization of MRR concepts, formulas, and optimization can help the manufacturers make well-informed decisions to establish a better competitive standing. With further development of manufacturing technologies, the necessity to control the optimization of material removal rates level will only grow, and thus this knowledge is going to be the key to successful manufacturing in the modern industry.

About GWT Worldwide: What is GWT Worldwide Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) is a global freight forwarding established and dedicated international logistics service provider that provides global supply chain solutions and cross-border e-commerce logistics services with professional expertise. As a company specialising in air freight, sea freight, Express rail transport, international express services, custom clearance, warehousing as well as support in shipping Amazon FBA products, GWT Worldwide provides service of high quality logistics to businesses operating around the whole world with the help of the high-tech and resources of a global net of reliable partners.