The Complete Guide to Threaded Holes: Manufacturing, Applications, and Best Practices

Threaded holes are one of the most important processes of manufacturing that allows reliable mechanical joints in an uncountable number

Threaded holes are one of the most important processes of manufacturing that allows reliable mechanical joints in an uncountable number

Threads using forming taps involve displacing material with no chip formation giving excellent thread strength and simplified operations in ductile

Flow lines Flow lines in injection molding are cosmetic flaws that leave streaks or wave patterns of plastic flow directions.

Optimization of the core and cavity in injection molding is used to improve the quality of a part, minimize the

The technology of in-mold labeling completely changes the technology of making plastic containers by combining labels with the process of

Both CNC lathes and CNC mills are the key precision manufacturing machines, however, they work on different principles: lathes rotate

The difference between 3-axis and 5-axis CNC machining is that you should make your decision based on your own project

CNC machining in 4-axis and 5-axis achieve high precision and can be applied to unique applications with 4-axis and 5-axis

CNC machines use complex software packages such as CAD design, CAM tools path and software to operate the machines. Common

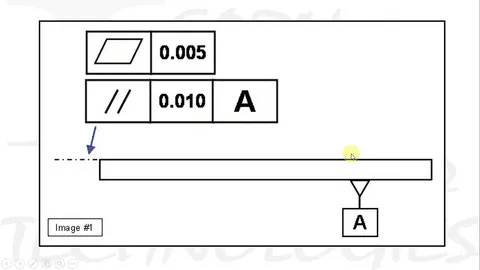

Flatness in Gd t is such an important type of form tolerance which guarantees that the surfaces are contained in

Ze Cheng Precision Mold Co., Ltd. setzt moderne japanische Ausrüstung und strenge Qualitätskontrollen ein, um hochpräzise Formteile und Maschinenkomponenten nach internationalen Standards herzustellen und weltweit zu exportieren.

WhatsApp uns