CNC (Computer Numerical Control) machining has transformed the automotive industry cnc machining from traditional machining with cnc technology into producing accurate, fast and dependable manufacture of various parts of vehicles. CNC machining is highly significant in production of quality auto components with close tolerances and intricate geometries starting from engine parts to structural bits. In this article, we will dive in to find out how automotive CNC machining works, its advantages, challenges, and a look at their applications in the world of automotive.

One of the major reasons why the CNC automotive machining is so important for the automotive sector is its ability to provide a consistent level of quality for high volume output. Parts like engine blocks, transmission housings, brake calipers, or even precision auto parts such as interior trims can be made many times over with slight variation, which guarantees reliability and safety, especially in the context of internal combustion engine performance . Moreover, CNC machines are able to operate various materials widely used in automobiles like aluminum, steel, and engineering plastics enabling manufacturers to achieve maximum performance and minimize weight on high quality components as well as meet the regulatory requirements in terms of durability and efficiency. With the change in automotive design trends towards electric and autonomous vehicles, the need for high precision and custom-machined parts will only increase further, further validating the central role of CNC machining in defining the future of mobility.

Apart from accuracy and material flexibility, CNC machining also minimizes production lead time, which is essential to the fast-moving automotive industry, facilitating rapid prototyping. CNC systems, including cnc milling, automate complex manufacturing processes and enhance cnc machining capabilities, reducing much of the labor from the traditional manufacturing methods, which makes the production faster and managed without human errors. This is not only effective in improving efficiency in operation but also enables automakers to react faster to a change in designs, market requirements or supply chain disruption. With vehicle models changing at a fast pace, particularly in the cut-throat markets for electric and autonomous vehicles, agility arising from CNC process offers a mandatory resource for innovation and prompt delivery of products.

What is Automotive CNC Machining?

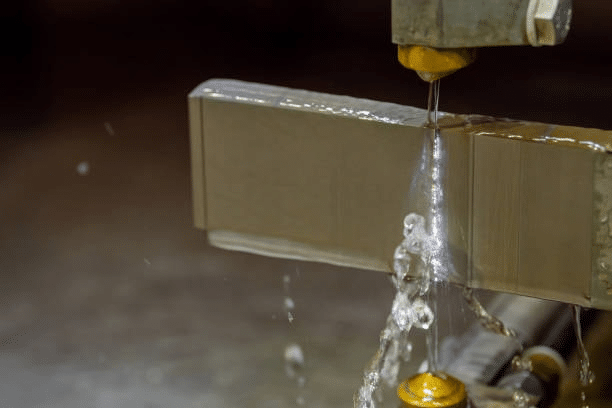

Automotive CNC machining is the use of automated machines to cut and shape material into precise automotive parts, allowing for the production of complex parts . Digital commands are used to program CNC machines to perform such operations like cnc turning with exceptional precision and a high level of accuracy, including; turning, milling, drilling, and grinding. The process is very versatile and can machine metals, plastics and composites that are very necessary for automotive manufacturing. Automotive production is another area in which CNC machining can be used to generate not only mass-produced pieces but also complex single pieces. This accuracy is vital in a business where parts integrity and performance have direct influence on safety, performance and efficiency.

In addition, CNC machining is very important in rapid prototyping in the automotive industry to allow the engineers and designers to quickly prototype and test products for new component designs before they move on to full-scale manufacturing. This makes innovation faster and time to market of new vehicle models or performance enhancement quicker. This level of precision in CNC machining also guarantees cross-compatibility of body panels components, minimising chances of errors and/or performance failures during assembly. No matter if you’re manufacturing custom components for motorsports devices, interior panels or mass-producing components for passenger vehicles, CNC machining provides unparalleled reliability, repeatability, and flexibility —all necessary attributes of the rapidly changing world of automobiles.

The other major benefit of the CNC machining in the automobile industry is its ability to combine with the digital designing tools like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. Such digital workflow powered by computer numerical control provides for accurate translation from complex designs to physical components while offering minimal variations. Engineers can simulate performance; change dimensions and optimize components in an environment which does not exist until virtual, well before the production process starts, so, there is maximum material waste and costly trial and errors. This integration does not only facilitate quicker development processes for automotive manufacturers through cnc machining services , but it also helps improve the quality control process to guarantee that each of the components is made to the precise specifications of modern cars – conventional or the next-generation vehicles.

Key Benefits of Automotive CNC Machining

Automotive CNC machining is associated with a broad range of advantages that make this type of machining the natural choice for producing complex automotive parts in the manufacturing industry . Among the greatest benefits are:

1. Precision and Accuracy

A main advantage of C NC machining is that it is able to generate parts with great precision and accuracy. In the automotive industry where small dimensional deviations already may lead to major problems, especially in the internal combustion engine part CNC machines guarantee the high precision and tight tolerances of parts. In this regard, it becomes particularly important especially for engine parts, gear components brake system valves suspension or transmission gears where accuracy is a preeminent necessity for optimum performance and safety.

2. Complex Geometries

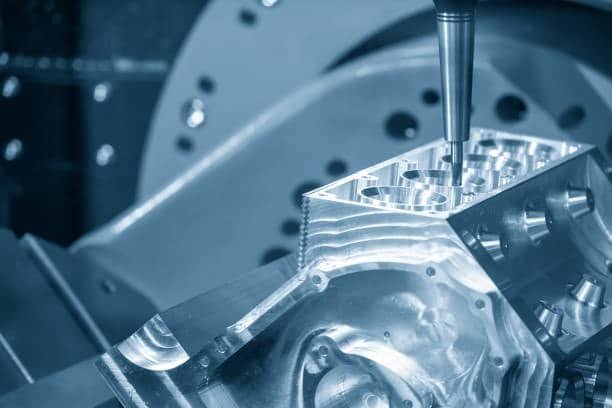

Automotive components are commonly molded with complex shapes and geometries, but these geometries are hard to achieve using conventional machining methods. CNC machines are capable of performing multi-axis moves and the process can generate complex parts with different contours, huge cavities, and internal feature. This flexibility is critical for the manufacture of such high-tech automotive parts as the turbocharger housings, exhaust system components intake manifolds, suspension components, chassis components, and made-to-measure fittings.

3. Consistency and Reproducibility

CNC machining guarantees that every part produced is just like the last and produces the same cnc auto parts. This degree of repeatability is especially important in high-volume automotive machining manufacture where CNC machining can produce high quality identical parts that must be manufactured thousands or at times millions without any quality variation.

4. Material Flexibility

With relatively convenient adjustments to some included parameters, one can perform automotive CNC machining on a variety of materials, from such metals as steel, aluminum and titanium, to such plastics as ABS, to such composites as ceramics and carbon fiber. The ability to work with a wide range of materials is why CNC machining is suitable for making components for all parts of the vehicle, structural, electrical, and mechanical.

5. Improved Production Efficiency

Through automation of complex tasks CNC machining is highly effective in improving production efficiency, especially for low volume production . When the program is developed, CNC machines, including drilling machines, will be able to operate round the clock hence minimizing human intervention and accelerating the manufacturing process. This efficiency is very important in automotive production of precision auto parts, which rely on precise machining ose success depends on cost control and time management for it to remain competitive.

Applications of CNC Machining in Automotive Manufacturing

A number of areas in machining for the automotive development use CNC machining, showcasing the various applications of cnc machining . The flexibility of the CNC technology enables it to be employed in small and large series of production. Some common applications in the automotive market clude the manufacturing of body components :

1. Engine Components

CNC machining is key in manufacture of high precision engine parts including cylinder heads, pistons, crankshafts, camshafts etc. Those components need close dimensional tolerances so that the engine can work properly. CNC machines are also capable of making complex passages inside for cooling purposes and oil flow which are important for any engine performance and life.

2. Transmission and Drivetrain Parts

The transmission system is yet another field where CNC machining is indispensible. Such parts, which are critical components like gears, shafts, starter motors and housings, have to be of high strength, emphasis, and accuracy so as to work smoothly even under the most strenuous operating conditions. CNC machining guarantees that such parts complement each other perfectly, which is crucial for automotive designers. , thereby minimizing friction and wear, thus improving the drivetrain’s overall performance.

3. Suspension and Steering Components

Suspension systems, steering parts, and lighting components should be built using close tolerances in order to make vehicles safe and comfortable. With the use of CNC machining, precise manufacture of parts such as control arms, dashboard components steering knuckles, shock mounts and struts can be done. These components must be able to stand considerable stresses and forces, especially in the automotive sector, and thus precision machining plays a vital role for reliability of these components.

4. Body and Structural Parts

CNC machining is also applied in the fabrication of structural automotive parts, such as the chassis, brackets and mounts, and in injection molding processe . Such things are not only to be integrated perfectly but also must meet high requirements of strength. CNC machines are very capable of cutting, milling and drilling materials like alloy steel such as steel and aluminium to form components with exact specifications which ensure structural integrity of the vehicle.

5. Custom Automotive Parts

For the case of custom vehicles, aftermarket parts or high-performance cars, CNC machining and 3d printing make it possible to create unique specification products by means of producing specialized components. Typical custom fittings, lightweight component, and performance improvement parts are also generally produced using the CNC machining process for the custom requirement of the customer.

Challenges in Automotive CNC Machining

Although, CNC machining has several advantages, it does have some challenges;

1. Cost of Equipment and Setup

The investment that is required for CNC machining in advanced machines and programming is large. Although it can be cost efficient in the long run, especially in high volume production of aluminum alloys, the CNC equipment and programming time can be prohibitively expensive for small scale manufacturers or new entries into the industry.

2. Material Costs

In many cases, automotive components need high-performance materials like titanium alloys and fuel pump systems , and carbon fiber composites. Despite their superior strength and weight saving benefits, these materials can be expensive to machine especially in the case where hard metals are involved that will accelerate tool wear.

3. Tool Wear and Maintenance

CNC machining especially when applied to hard metals can cause quick tool wear. High Frequent change of tools, and Operations on machines can increase operation cost and downtime, especially in bustling manufacturing facilities.

Conclusion

Automotive CNC machining is an integral part of current day manufacturing technology in automobile production enabling unmatched precision, efficiency and versatility in the production of vital automotive components. From engine parts through structural components, CNC machining makes it possible to create high quality parts that satisfy rigorous performance and safety standards. What makes CNC machining and 3d printing permanent foundation of the automotive industry is its readiness to deal with complex geometries and a massive production round the clock, using a variety of materials.

Furthermore, the combination of sophisticated CAD/CAM software with CNC machines has again taken the automotive manufacturing to the new heights by smoothening the design to production process. Engineers can now experiment with, test and optimize parts virtually before having them physically built, thereby decreasing the amount of time to develop and the material that is wasted. In addition, CNC machining facilitates customization where manufacturers are at liberty to design custom components for specialized vehicles or those designed on a limited edition basis at the utmost convenience. The more vehicles adopt technological advancements such as sensors, lightweight materials, as well as precision-built systems, the greater the role of CNC machining, which offers a measure of reliability and the ability to be flexible enough to fit into new demands of the automaker market.