Electrical Discharge Machining (EDM), such as wire edm, is a non-traditional process of machining that utilizes controlled electrical discharges (sparks) to remove a material from a workpiece. EDM is mainly focused at creating detailed shapes and fine details primarily for hard metals that cannot be machined in any other way, while also optimizing cutting speeds . Advanced machining procedure is very important in industries like aerospace, automotive, mold making and tool making field.

The fundamental notion of the process of EDM is that of sparking that occurs between the tool electrode and the workpiece, which are isolated by a dielectric fluid and driven by electricity . Such prime sparks induce localized heating that melts and volatizes the material in contact, allowing for extremely detailed cuts and designs, as well as optimizing cutting speeds. In this article, we will overview the different aspects of an EDM machine, the wire cut edm process, and what it brings to the modern process of production, highlighting this innovative method .

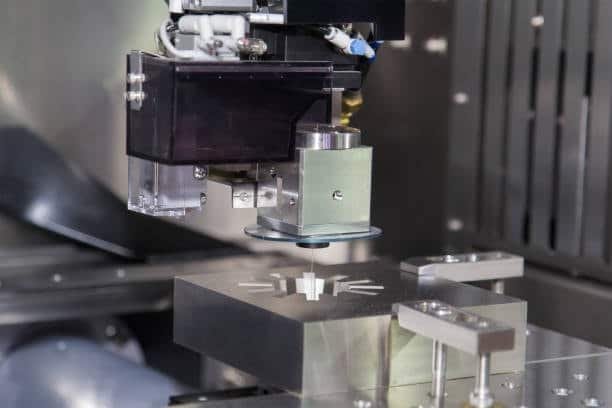

And in particular, the wire cut EDM process is notable for its capability to generate precision parts of very complex shapes; it does that by moving a thin electrically charged wire through the workpiece. This technique is particularly advantageous when it comes to producing components that have the need to have sharp internal corners, tight tolerances, or fine contours which may not be manageable through conventional machining. In comparison to conventional cutting, the wire EDM does not apply any mechanical force on the material hence enhancing stability of dimensions and availing it from distortion. Consequently, it has become a preferred process in such industries as tool and die making, medical implants, and micro-component production where precision and reliability are of extreme importance.

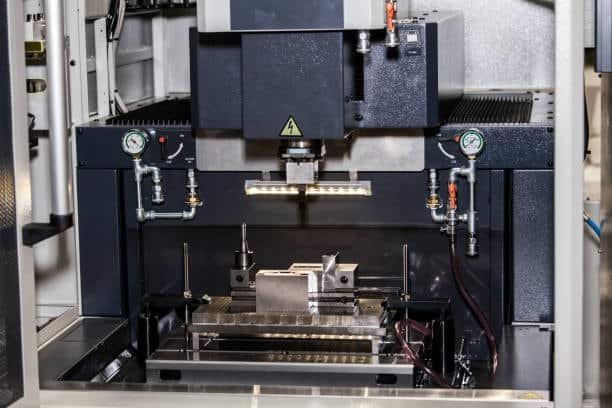

Key Components of an EDM Machine

An EDM machine, as illustrated in the edm machine diagram, has a number of fundamental parts, including two spools each part being essential to the success of the machining process. These include:

- Electrode: Material for the electrodes is usually made of copper, graphite or other conductive materials. And it is the tool that generates sparks to wear away the material from the workpiece. The form of the electrode is adjusted to the needed contour and its motions are regulated during the process of machining.

- Workpiece: The workpiece is the material that is to be machined. It is usually manufactured from a conductor such as steel, titanium, or tungsten. The workpiece is immersed in a dielectric fluid acting as a coolant and as an insulator.

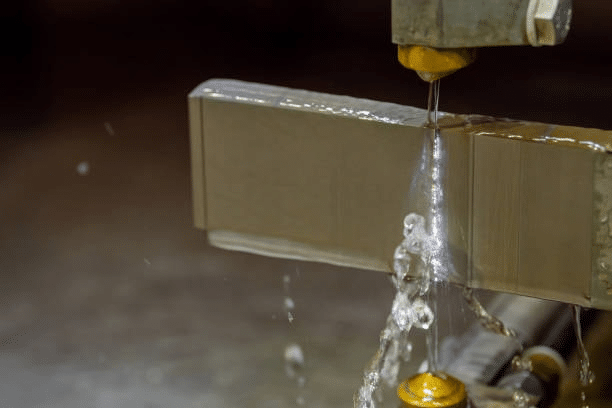

- Dielectric Fluid: Basically the dielectric fluid is either a hydrocarbon based oil or de-ionized water which fills the space between the electrode and the work piece. This fluid serves multiple functions: it cools electrode and workpiece, flushes off the debris from process of machining, and offers the required insulation so that sparking is kept under control.

- Control Unit: The control unit is the mind of the EDM machine. It controls power supply to produce electrical discharges and controls the movement of the electrode with tremendous accuracy. Today’s modern EDM machines are equipped with CNC (computer numerical control) systems that facilitate extremely automated & accurate processes.

- Power Supply: The electrical energy that is needed for the process of sparking is provided by power supply. It regulates the duration and intensity of the discharge for each iteration which has two direct results: the quality of the produced part’s surface and precision.

- Servo System: The servo system is responsible for correct electrode positioning and maintaining the electrode and workpiece gap constant. It guarantees that the cutting action moves on smoothly without being off the programmed track.

The EDM Process: Step-by-Step

Wire EDM process possesses several stages which are crucial to the successful machining of a part. Here is the breakdown of what can happen during the EDM process, which may depend on the frequency of the electrical discharges:

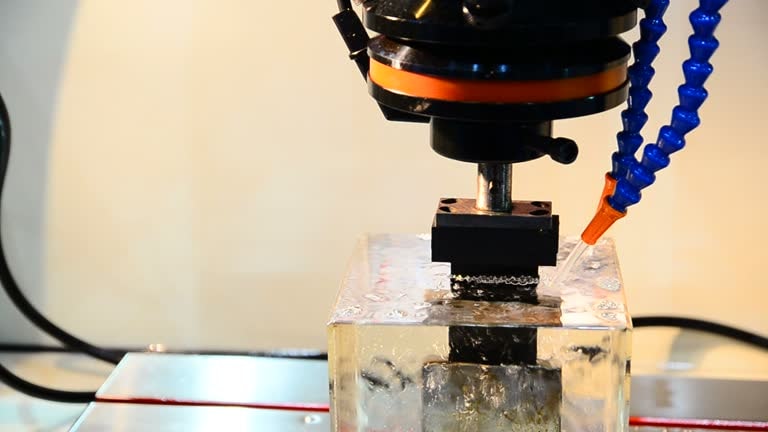

- Setup: First, the workpiece is fixed into the machine table and the electrode is fixed above the workpiece. The electrode is precisely adjusted to the part’s contours; getting the shape required. Then a dielectric fluid is synthesized between the electrode and the workpiece.

- Spark Generation: The control unit of the EDM machine activates the power supply and generates a stream of sharp electrical discharges between the electrode and the workpiece. These sparks are so strong, that they create a local heat, melting and vaporizing the material on contact.

- Material Removal: Further striking of the workpiece with the sparks removes small particles of the material, thus shaping the part. The material scrapping is cleared by the dielectric fluid making the work clean ensuring that the machining process continues as normal.

- Electrode and Workpiece Movement: Both the electrode and workpiece are precisely and accurately moving and during the machining process. The electrode is usually lowered slowly, and sometimes also the workpiece may be moved in a controlled manner to develop the desired shape. This is controlled by servo system and cnc system.

- Finishing: After the machining has been done, the part is taken out from the machine and cleaned. Other than that, the surface finish of the part may need improvement according to the application. However, fine finishes are produce by EDM with very little need to do post machining.

Advantages of EDM Machining

EDM embraces many advantages over conventional forms of machining, making it a preferred method in modern manufactur . There are several benefits including the ability to machine materials like brass and create precise holes .

- High Precision: EDM machines can create parts of such high degree of precision with very tight tolerances. The process makes possible the development of intricate and complex geometries, hard to, if not impossible, to obtain using traditional machining techniques.

- Ability to Machine Hard Materials: Unlike previous methods, EDM is free from mechanic cutting forces which makes it possible to machine such hard materials as hardened steel, titanium, carbide etc. against all odds.

- Minimal Tool Wear: Since the electrode is non-contact with the work piece (except for the electrical discharges), tool wear is reduced which means peripheral longer life and less frequent tool chapters.

- No Mechanical Stress: Since the process is based on electrical discharges as opposed to physical cuts then there is no mechanical stress applied to the work-piece. This is therefore great for thin walled or delicate parts that may be damaged from normal machining.

- Complex Shapes and Designs: EDM has excellent efficiency in producing parts with complex form, internal cavities, and fine details. The extensibility of the process permits perfect, minute designs without requiring a lot of tooling or remolding.

Applications of EDM Machines

EDM is popular in different specialties because it is typically known for its precision and capability to machine hard materials. Some common applications include the machining of precise holes and achieving a smooth surface .

- Tool and Die Manufacturing: EDM is widely applied in the production of molds and dies where details and high degree of precision is required. It is particularly useful when designing complicated features in the cavities of the mold, which could not be achieved using traditional methods.

- Aerospace and Automotive: The sectors of the aerospace and automotive industries need serious components from high-strength materials that would have high-performance standards. EDM is able to provide accurate machining of turbine blades, engine parts or precision gears.

- Medical Devices: In medicine; ram EDM is used to produce very accurate and detailed parts for items in the medical devices category including surgical tools, implants, and diagnostic instruments.

- Jewelry and Electronics: electrical discharge machining

is used in producing tiny details in jewelry and in electronics and other minute and complex pieces of products that need precision.

Conclusion

The EDM machine, including sinker edm, is an important and irreplaceable tool of the modern manufacturing industry that ensures unmatchable precision in machining hard and complicated materials. As technology advances, including the integration of diamond guides and wire, i t will be no different for EDM machines which will continuously get better and better, and even be capable of achieving what would have been impossible in precision machining.

On top of that, the one-of-a-kind characteristic of EDM (Electrical Discharge Machining), namely, its ability to machine electrically conductive materials and those that can conduct electricity irrespective of their hardness, showcasing its high conductivity and versatility with different metal types, ets it apart from the deionized water traditional ones. The technology enables creation of complex geometry using electrode wire, fine details and ultra-tight tolerances, which is an absolute necessity in aerospace, medical device manufacture, and injection molding industries. With the further implementation of automation and digital controls into EDM systems, the process is getting faster, more efficient, and more adaptive to the demand for custom and small-batch production – going against what can be achieved by precision manufacturing.