Meta Description: Discover the complete guide to silicone injection molding of liquid silicone rubber (LSR) using a liquid injection molding machine . Learn about processes, applications, benefits, and best practices for high-quality LSR manufacturing in 2025.

What is Liquid Silicone Rubber (LSR) Injection Molding?

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume. This advanced manufacturing technique combines the precision of injection molding with the exceptional properties of liquid silicone rubber, creating several mechanical components that offer superior performance across various industries.

The LSR injection molding process involves mixing two-part liquid silicone components that cure under heat to form flexible, durable elastomeric parts. The process delivers exceptional accuracy, consistency, and efficiency for producing complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods.

The Science Behind LSR Material Properties

Liquid silicone rubber has good elongation, high tear and tensile strength, excellent flexibility, and a hardness range most commonly between 5 to 80 Shore A. These mechanical properties make medical grade silicone LSR is an ideal material for silicone rubber parts applications requiring durability and flexibility, particularly for human tissue contact.

The unique molecular structure of LSR in the lsr molding process provides several key characteristics that set it apart from other elastomers. The platinum-catalyzed curing system creates stable cross-links that maintain their integrity across extreme temperature ranges. This stability translates to consistent performance in demanding applications where other materials might fail or degrade over time, making the lsr molding tool crucial .

LSR Injection Molding Process Overview

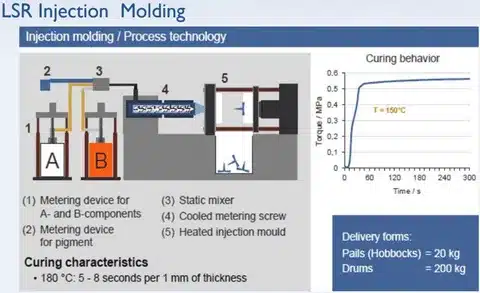

During the process, several components including a metered pumping device, supply drums, and others are necessary for the injection molding machine: an injector, a metering unit, a mixer, a nozzle, and a mold clamp, among others. The LSR injection molding process begins with precise metering using a metering pump of the two-part liquid silicone components.

The liquid silicone is supplied in two containers, Part A and Part B, then typically mixed at a 1:1 ratio in the molding machine . This mixing occurs in a specialized system that ensures complete homogenization before injection into the heated cavity using a static or dynamic mixer where cross-linking occurs rapidly.

Temperature Considerations in LSR Processing

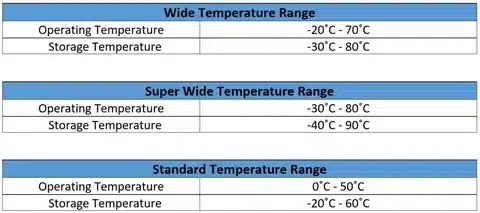

LSR injection molding is flexible down to -58°F and retains its properties up to 392°F. This remarkable temperature range makes liquid silicone rubber material LSR suitable for applications that must resist extreme temperatures, optimizing the molding cycle in extreme environments, ultimately reducing material waste.

The curing process temperature during molding typically ranges from 300°F to 400°F, allowing for rapid cycle times while ensuring complete cross-linking. The material’s ability to maintain its properties across such a wide temperature spectrum is one of the key advantages that drives its adoption in critical applications.

Key Industries and Applications for LSR

LSR injection molding serves numerous industries with demanding requirements. In the medical sector, silicone rubber injection molding LSR’s biocompatibility and sterilization resistance make it ideal for surgical instruments, seals, sealing membranes and implantable devices that may come in contact with body fluids . The automotive industry relies on LSR for gaskets, seals, and components that must withstand extreme temperatures and chemical exposure.

Electronics manufacturers use liquid silicone rubber injection LSR for protective seals, keypads, and components requiring excellent dielectric properties. Consumer products benefit from LSR’s durability and tactile properties in items like kitchen utensils, molded components in sporting goods, and personal care products. The aerospace industry utilizes LSR for seals and components that must perform reliably in harsh environments.

Advantages of LSR Over Traditional Materials

The benefits of thermoplastic injection molding, including compression molding, lsr molding injection molding extend far beyond simple material properties. The processing advantages include faster cycle times compared to traditional rubber molding, reduced flash and waste, and the ability to produce complex geometries with tight tolerances, often minimizing the need for post molding secondary operations . The material’s self-releasing properties often eliminate the need for mold release agents, reducing contamination risks and improving surface quality.

LSR’s chemical inertness makes it suitable for food contact applications and medical devices, similar to compression molding processes. where material migration must be minimized. The material’s resistance to UV radiation, ozone, and various chemical solutions ensures long-term performance in outdoor and industrial applications.

Equipment Requirements and Setup

Successful LSR injection molding requires specialized equipment designed to handle the unique characteristics of liquid silicone materials. The static mixer metering system must accurately proportion the two components while maintaining their separation until mixing occurs. Pumping systems must be designed to handle the low viscosity of liquid silicone without introducing air bubbles that could compromise part quality.

The injection unit requires precise temperature control to prevent premature curing while ensuring proper flow characteristics. Mold heating systems in the heated cavity must provide uniform temperature distribution to achieve consistent curing throughout the part geometry. Proper venting is critical to prevent air traps and ensure complete mold filling.

Mold Design Considerations for LSR

Mold design for LSR injection molding differs significantly from conventional thermoplastic molding. The low viscosity of LSR requires careful attention to parting line design and flash control. Gate design must balance filling efficiency with part quality, often requiring specialized gate types that minimize material waste and improve surface finish.

Cooling system design must account for the exothermic curing reaction while maintaining precise temperature control. Proper venting is essential to prevent air entrapment and ensure complete filling of complex geometries. The lsr molding tool material selection must consider the chemical compatibility with LSR and the ability to withstand repeated thermal cycling base forming silicone.

Quality Control and Testing Methods

Quality assurance in thermoplastic injection molding LSR injection molding involves multiple testing protocols to ensure consistent part performance throughout the production process . Physical property testing includes durometer measurements, tensile strength evaluation, and elongation testing. Thermal analysis confirms proper curing and cross-link density throughout the part.

Chemical compatibility testing ensures the material meets application-specific requirements for exposure to various substances. Dimensional inspection verifies that parts meet geometric specifications, while visual inspection identifies surface defects or contamination. Accelerated aging tests predict long-term performance under service conditions.

Common Challenges and Solutions

LSR injection molding presents unique challenges that require specialized knowledge and experience to overcome. Flash control can be difficult due to the low viscosity of the material, requiring precise mold design and processing parameters, including a cold runner system . Air entrapment may occur in complex geometries, necessitating careful venting design and injection speed optimization.

Contamination control is critical since LSR is sensitive to certain substances that can inhibit curing. Proper material handling, storage, and processing procedures, along with intensive distributive mixing, must be implemented to maintain material quality and minimize material shrinkage . The liquid injection molding process t emperature control throughout the system is essential to prevent premature curing or incomplete cross-linking.

Cycle Time Optimization Strategies

SILASTIC™ liquid silicone rubbers can help with your superior processing time, reduced cycle times and lower production costs. Optimizing cycle times in LSR injection molding requires balancing several factors including part thickness, mold temperature, and cure characteristics.

Advanced processing techniques such as variable mold temperature control and optimized injection profiles can significantly reduce cycle times while maintaining part quality. Proper mold design with efficient cooling systems, including a static mixer, and strategic wall thickness optimization contributes to faster cycles without compromising mechanical properties.

Surface Finishing and Post-Processing

LSR parts often require minimal post-processing due to the material’s self-releasing properties and ability to achieve excellent surface finishes directly from the mold. However, certain applications may require additional treatments such as surface texturing, printing, or secondary bonding operations.

The chemical inertness of cured LSR can make certain surface treatments challenging, requiring specialized primers or surface preparation techniques. Proper mold surface preparation and maintenance are essential for achieving consistent surface quality across production runs.

Cost Considerations and Economic Factors

The economics of LSR injection molding involve multiple factors beyond material costs. While LSR material costs may be higher than some alternatives, the processing advantages often result in lower overall production costs. Reduced cycle times, minimal waste, and lower rejection rates contribute to improved cost-effectiveness.

Tooling costs for LSR injection molding may be higher due to the specialized requirements for temperature control and precision machining. However, the longer tool life and the use of an automatic shut off valve along with reduced maintenance requirements often offset the initial investment over the production lifecycle.

Environmental and Sustainability Aspects

LSR injection molding offers several environmental advantages compared to traditional rubber processing methods liquid silicone rubber molding. The material’s chemical stability and resistance to degradation result in longer product lifespans, especially when using high consistency rubber, thus reducing replacement frequency and waste generation. The minimal waste production during molding contributes to more sustainable manufacturing practices.

The ability to achieve precise part dimensions and consistent quality reduces the need for secondary operations and rework, further improving environmental efficiency. LSR’s biocompatibility and electrical properties along with its chemical inertness make it suitable for applications where environmental safety is a concern, as LSR has demonstrated superior compatibility .

Tendencias e innovaciones futuras

The LSR injection molding industry continues to evolve with technological advances and expanding applications. LSR 2024 unites professionals from various industries and disciplines to discuss technological and scientific developments in liquid silicone rubber and related materials, including liquid silicone injection molding . Emerging trends include the development of specialized LSR formulations for specific applications and the integration of smart manufacturing technologies, including the use of a dynamic or static mixer .

Advanced process monitoring and control systems are enabling more precise parameter control and real-time quality assurance. The development of new mold technologies and heating systems is improving processing efficiency and part quality. Sustainability initiatives are driving the development of more environmentally friendly LSR formulations and processing methods.

Selecting the Right LSR Grade

Choosing the appropriate LSR grade requires careful consideration of application requirements and processing conditions. Factors to consider include hardness requirements, chemical resistance needs, temperature exposure, and regulatory compliance requirements. Different LSR formulations offer varying characteristics such as flame resistance, electrical conductivity, or enhanced tear strength.

Working with experienced suppliers and processors is essential for selecting the optimal LSR grade and processing parameters. Prototype testing and validation of uncured liquid silicone should be conducted to confirm material performance under actual service conditions before committing to full production.

Working with LSR Manufacturing Partners

Successful LSR injection molding projects require collaboration with experienced manufacturing partners who understand the unique aspects of the injecting device in liquid silicone processing. At GWT Worldwide, we specialize in global freight forwarding and supply chain solutions that support LSR manufacturers in moving their products efficiently across international markets. Our comprehensive logistics services include air freight, sea freight, China-Europe railway transport, and customs clearance support, ensuring your LSR components reach their destination safely and on time.

When selecting manufacturing partners, consider their experience with LSR materials, quality certifications, and ability to provide design support throughout the development process. Effective communication and collaboration are essential for achieving optimal results in LSR injection molding projects.

Conclusión

Injection molding liquid silicone rubber represents a sophisticated manufacturing process that delivers exceptional performance across diverse applications. The combination of LSR’s unique material properties with the precision of injection molding creates opportunities for innovative product designs that would be impossible with traditional materials and processes. Success in LSR injection molding requires understanding the material characteristics, proper equipment selection, careful mold design, and adherence to specialized processing techniques.

The continued advancement of LSR technology and processing methods promises even greater opportunities for manufacturers seeking durable, high-performance elastomeric components. As industries continue to demand higher performance and reliability from their products, LSR injection molding will play an increasingly important role in meeting these challenging requirements.