Swiss screw machining is a very specialized and productive method of producing very small components with small tolerances and accuracy, enabling rapid production . For this process the industries where it is critical to have precision, speed and workability with various kinds of materials are most advantageous. Swiss screw machining operation is known for its capability to produce high-volume production runs with complex geometries and this process has become standard in various industries including the aerospace, automotive, medical device manufacturing and electronics. In this article we will delve into what SWISS SCREW MACHINING is, the benefits and its applications and how it works.

What Is Swiss Screw Machining?

Swiss screw machining, otherwise referred to as Swiss-type turning, is a micro machining process which involves the use of a head stock that slides and a series of cutting tools to form material specialty to very precise small parts, creating intricate design . This approach derives its name from its birth place in Switzerland, which was its originating country where it was developed to produce small intricacies for the watch making industry. Currently, screw machines from Switzerland are used to produce a large variety of components with high accuracy and complex shape of geometry, especially in cases when rapid output and close precision is needed.

How Does Swiss Screw Machining Work?

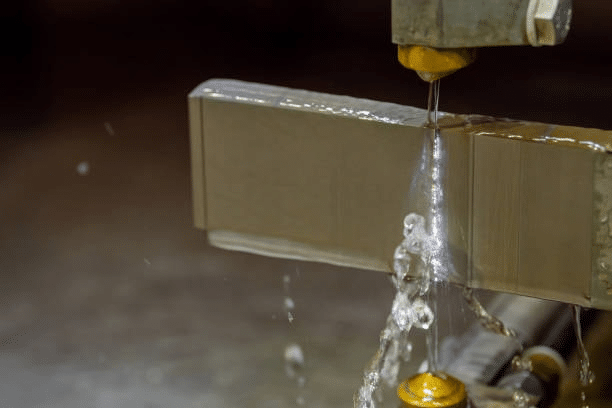

Swiss screw machines shop hold workpiece on rotating spindle and have multiple cutting tools that include drills, lathes and the milling cutters surrounding the piece. When operating the spindle, the material is supplied and shaped in the desired form. Swiss screw machines are different from conventional lathes where the tool is static on the main spindle and the workpiece rotates, or vice versa, that the workpiece is statically bolts held on the main spindle and the tool rotates while the workpiece is in a fixed motion around the cutting axis to produce the required features.

Key Advantages of Swiss Screw Machining

Several advantages of cnc screw machine make it a very desirable process for manufacturing precision parts in high-volume runs. Among the major benefits are such items as:

1. High Precision and Tight Tolerances

Swiss screw machining is well known for the fact that it can achieve tight tolerances to as little as a few microns. This makes it perfect for industries where part accuracy is important, such as aerospace and the making of medical devices.

2. Complex Geometries

The capability of Swiss screw machines to employ as many cutting tools as needed, enables the manufacture of parts, having intricate shapes, grooves and features. Components that would be hard or impossible to make using traditional technology can be easily produced through Swiss screw machining.

3. High Production Efficiency

Swiss screw machining is for mass production. The process control is largely automated minimizing need of manual intervention, therefore, the production of parts is done in a timely and efficient manner.

4. Reduced Tool Wear

Swiss screw machines utilize a process that reduces the contact of the cutting tool with the workpiece. Tool wear is therefore minimized, and the lifespan of tools increased.

5. Versatility with Materials

Using Swiss screw machining is possible when working with a range of different materials for example metal, plastics and composites control, achieving high production volume . Regardless of whether you produce parts from stainless steel, titanium, brass or thermoplastics control, Swiss screw machines can easily deal with a variety of materials and provide great results in various industries.

Applications of Swiss Screw Machining

Swiss screw machining is domain of industries which need precision, high volume and need various material. Among the listed key applications are:

1. Aerospace

In the aerospace industry, Swiss screw precision machining is the process used to produce small reliability, lightweight and high precision parts like fasteners, brackets and connectors.

2. Medical Device Manufacturing

Medical industry requires great level of precision, particularly when it comes to implants, surgical tools, and diagnositic devices.

3. Automotive Industry

Swiss Screw Machining is used to manufacture small intricate parts that are later used for high performance automotive applications such as engine components, fuel systems and sensors.

4. Electronics

Swiss screw machining is commonly used in the electronics field to fabricate connectors, terminals, and, small housings for electronics parts.

5. Watchmaking

Swiss screw machining was originally a specialized process that was created for watchmaking but continues to play a key role in the manufacture of tiny pieces of machinery that are important in watches and timepieces.

Challenges of Swiss Screw Machining

Although some of the advantages of Swiss screw machining are numerous, it has some challenges. It is a costly process in setting up the machine due to the precision needed, and the complexity of tooling especially for low-volume runs.

Conclusion

Swiss screw machining is a fundamental process in manufacturing that presents the ability to make the most accurate and detailed parts with close tolerances. With the capacity to process complex geometries, high-volume production capacity, and heterogeneous materials, it is irreplaceable for the aerospace, automotive, medical devices, electronics, and watchmaking industries.