Meta Description: Practice perfect welding sheet metal by using the best MIG and metal inert gas welding methods. Discover professional secrets of how to prevent burn-through and manage heat and get want you want which is to get perfect welds with thin metal material.

Welding of welding sheet metal is one of the most difficult but the necessary skills in modern fabrication. Be it body work of cars, heating systems, or even in industrial, the art of welding thin materials demands perfection, skill, and the equipment including a filler rod, making the welding process crucial . The following is a complete guide that will bring you around everything that you need to know about successful mig welding of sheet metal using MIG and TIG.

Understanding Sheet Metal Characteristics

The common uses of Sheet metal falls between 16-26 gauge, or 0.5mm to 2.5mm of thickness. When thin metal is welded, the primary goal is to prevent warping, burn-through, and an excessive amount of heat-affected zones in the surrounding metal, while carefully controlling the weld puddle . but to have sufficient mechanical strength of the weld to suit the application. These thin sheet metal are thin and easily distort and burn-through under heat so there are special techniques and strong control of parameters required.

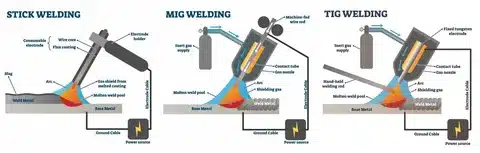

Why MIG and TIG Are Ideal for Sheet Metal

To overcome these problems, the most control of the heat generated is offered by short-circuit transfer MIG (short arc), tig welding and pulsed mig welding processes. The processes provide the critical heat controls required on thin materials where welders can produce sound joints which do not break the integrity of the base metal.

Essential MIG Welding Setup for Sheet Metal

Setting up is essential in successful sheet metal welding. The choice of continuous solid wire electrode is significant in the acquisition of good weld outcomes. When connecting with wire always use the smallest wire diameter you can as the narrower the wire the less heat required to melt and less heat applied to the metal. To minimize the control difficulty and to maintain control, sheet metal (mostly) requirements are best matched by 0.023 or 0.024-inch diameter wire with the appropriate wire feed speed .

Choosing the Right Wire Diameter

As a thumb rule, you cannot go over too much material of a filler metal when compared to that of the base metal. A no. 023 or no. 024 inch wire is advised to be used on most light gauge sheet metal work to match the filler material . With 18-gauge or heavier material you can graduate to 0.030-inch wire, but the heat input must be closely guarded.

Shielding Gas Selection for Optimal Results

Choice of gas also has a remarkable influence on quality of weld and heat input. A higher, tungsten inert gas, e.g. 75 percent argon/25 percent carbon dioxide, should always be used. Argon transports less heat than CO2 is, especially towards the cooler edge, and you will feel less spatter. This gaseous blend gives superior arc stability and keeps the transport of heat to the base metal to a bare minimum.

TIG Welding Fundamentals for Sheet Metal

The better control provided in thin materials by gas tungsten arc welding, such as tig welding, makes critical applications its favored alternative. Choosing consumable electrodes and flux cored wires is especially relevant when dealing with sheet metal. Forget the bigger 1/8-inch tungsten electrode and replace with small. The first choice is the ceriated tungsten with thoriated tungsten as an alternative.

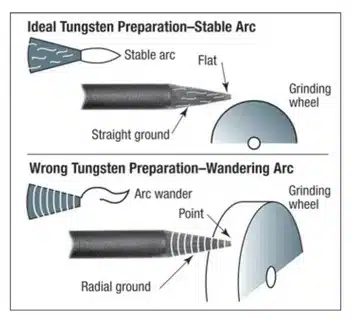

Tungsten Electrode Preparation and Selection

The tungsten, .020, .040 and 1/16-inch diameter are popular. Smaller electrodes will also be easier to start and operate in lower heat conditions and this will prevent the problem of burn-through and control molten metal and enable you to direct the arc to a smaller area. Appropriate preparation of the electrode, often assisted by a grinding wheel, provides stable convection and constant initiation of the arc.

Advanced TIG Techniques with Inverter Technology

New age inverter-based TIG welder units are very useful in welding thin sheet metal, offering enhanced control. An inverter-source power is needed to achieve best outcome on welding thin metal, particularly thin aluminum. Such machines give more control over an arc and can manage applications without excess metal. that require a specific temperature more finely which is important to work with materials that are easily burned.

Filler Metal Selection Strategies

The selection of filler metals effectively influences the quality of weld and the needs of heat input. It is also good to choose a filler material with corrosion resistance that is slimmer than the mild steel base metal as is possible. This will make sure that you do not overheat the base metal, especially in the heat affected zone, by the time filler metal has a chance of joining with it.

Heat Control Techniques and Travel Speed

Ditto to avoid dead spots (burn through), or warping: do not whip or weave the torch, the longer the arc stays in one place, the hotter it gets. Be in a straight line while traveling, and get the best speed of traveling that would ensure continuous welds and good bead profile. Reliably maintained travel speed means evenly spread heat distribution and no overheating in one area, preventing blowing holes .

Push vs. Pull Technique Applications

Weld direction and angle of torch play an important part in heat input and penetration. Prevention of burn-through can also occur through application of a push method of the MIG gun, or the skip welding technique . This is because it aims the wire at the cooler end of both the base metal and weld puddle instead of pulling the gun which is aimed at the hotter end of the puddle – this poses a greater possibility of a blowout when working with thicker materials.

Skip Welding for Distortion Control

Distortion and warping due to unevenly distributed heat makes destruction to those parts that ought to fit together. As evenly as possible, distribute heat to reduce warping in metal objects . This can be done with the help of a process called skip welding where a number of sporadic or stitch welds is performed. In this method, welds can cool the sections amidst them which avoids global overheating.

Heat Dissipation Using Backing Bars

In order to ensure that the heat-exposed area might cool off at a higher rate than atmospheric cooling can manage, a backing or chill bar should be in coverage contact with the heat-exposed area. This may be as elementary as a piece of metal (typically copper or aluminum since these are the best at dissipate heat faster) clamped on the back side of the weldment. Such a process helps to eliminate heat over a welding space quickly to avoid warping and through-burn, making plug welds an effective technique .

Critical Fit-Up Requirements

Sheets should be properly prepared in order to ensure welding. Welding of thin metals requires good fit-up. Consider a butt weld on the metal of 20- to 24-g, especially when using mig welding techniques . Should there be a failure to make contact with each other even 1 / 16th of an inch, you have unwelcome hole that can disrupt the weld bead and allow burn-through to enter, especially with thicker metal. and a gap that cannot absorb the heat.

Joint Design Considerations

Concerted design is critical towards successful welding of thin materials. It might also be wise to redesign bad joints and add more heat resistance structures. In the non-critical area, continuous beads can frequently be substituted by plug welds unlike tig welding, therefore reducing heat input during the arc welding process ., but still providing that structural integrity.

Power Source Settings and Parameters

Good sheet metal welding starts with proper machine setup. The secret to welding on a MIG sheet metal, especially when welding thin, is this, run it in the same settings like a vertical up weld. This will reduce the amount of heat introduced, but still provide the strength of the joints by means of penetration.

Preventing Common Welding Defects

The most typical defect in the process of sheet metal welding is burn-through. Heat management principles and application of the right techniques will eliminate this that comes from too much heat at a high cost. Also, the constant arc length and traveling speed prevents porosity and fusion.

Stainless Steel Sheet Metal Welding

In the case of 304 stainless steel welding can be done with ER308, ER308L and ER308LSI incompatible wires, but 316L stainless will require a 316L welding wire. Using such materials, a tri-mix gas comprising 90 per cent, helium, 8 per cent, argon to 2 per cent, CO2 is used. Stainless steel has a lower conductivity than carbon steel and so more attention should be paid to manage heat when using the welding gun .

Aluminum Sheet Metal Considerations

Common Aluminum sheet alloys are 3003 and 5052. Either of these would use filler metals 4043 or 4943. clay The 5356 filler metal is also applicable to 5052 materials. Aluminum has high thermal conductivity and hence must be adjusted to meet regular techniques for metal sheets and preheating.

Métodos de control de calidad e inspección

The main method of sheet metal welds quality control is visual inspection. Search to find similarity of appearance of beads, good penetration without burn-through and little distortion. In extremely critical points dye penetrant testing may be used to detect surface defects.

Safety Protocols for Sheet Metal Welding

Flowing fully is in itself very important when working with thin materials that cause more fumes, especially per inch of linear travel due to high speeds of movement and concentrated heat. Have proper extraction systems with personal protective equipment which suits the materials of what is being welded.

Troubleshooting Common Problems

Responding to welding flaws in time eliminates the wastage of money on rework operations. The cause of burn-through is usually excessive heat, bad fit-up or dirty base-metal when working with thicker materials . Porosity is usually the sign of either contamination or inadequate shielding gas coverage.

Advanced Applications and Industry Uses

The field of welding in sheet metal is used in as many industries as construction with the aerospace components being welded using precision pieces of TIG welding and the panels on a car being welded using the efficient pieces of MIG. Knowledge of certain requirements of an industry is what can avert the selection of improper technique.

About GWT Worldwide – Your Logistics Partner

GWT Worldwide (Shenzhen Guanwutong International Freight Forwarding Co.,Ltd.) is one of the professional logistic service providers focusing on the areas of global freight forwarding, end-to-end global supply chain solutions, and cross-border e-commerce logistics. Being an expert in air transport, sea transport, China-Europe railway transportation, and Amazon FBA transportation, we offer the most efficient and secure transportation of your welding equipment and materials to their destinations through a well-structured logistic path.

Conclusión

To achieve the mastery of welding thin sheet metal, it would be necessary to understand the peculiarities of working on the surface of thin materials as well as introduce suitable methods of heat control. The correct choice of equipment, technique improvement, and constant practice is the key to success. By adhering to the rules provided in this guide, the welders will have an opportunity to come up with professional-standard work and to evade the most typical mistakes of welding thins.