CNC Turning Service

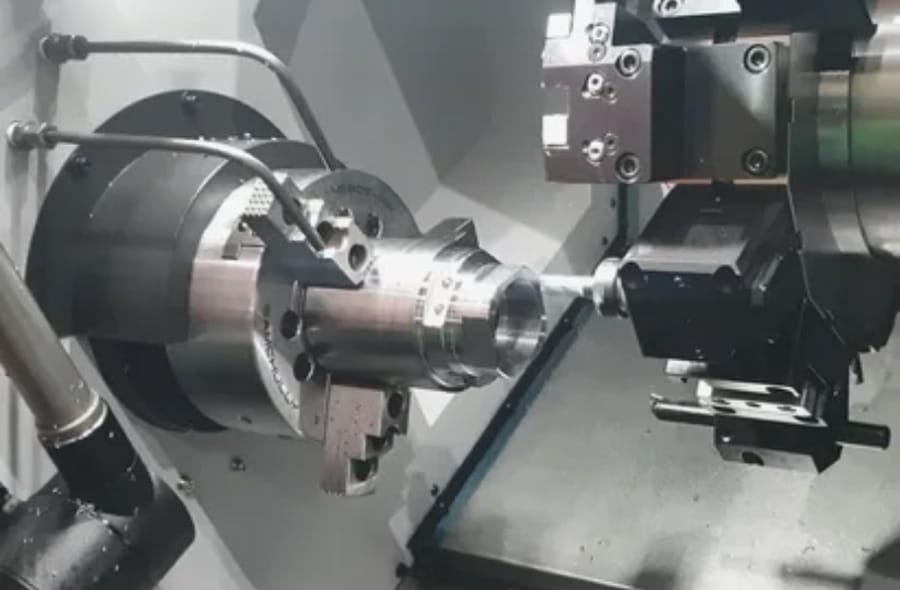

CNC Turning for Maximum Performance and Long-Lasting Durability

- Ideal for Long, Cylindrical & Threaded Parts

- Unrivaled Precision for Rotating Components

- Delivers Outstanding Finish and Perfect Symmetry

An NDA can be signed if needed before the quotation.

Reliable CNC Turning Services for High-Quality Parts

Zcmould focuses on offering expertise in CNC turning that helps produce top-quality custom parts within a short time frame. With the help of advanced turning machines and our expert team, we make parts that have exact dimensions and complex shapes. Thanks to aluminum, brass, steel and different materials, our CNC Turning Service is perfect for making shafts, bushings, couplings and anything with threads.

You can rely on zcmould for all your CNC turning because our commitment to solid quality, dependable work and accuracy will show.

- 24/7 Turning Service

- Diversified custom processing

Affordable Pricing

Experienced Engineers

TURNING/MILLING ADVANTAGES

What Can You Expect from Our Turn-Mill Machining?

Short Process Chain & High Production Efficiency

All or most processes can be done in a single step with turn-mill machining which reduces the whole production time. When you use this, you are sure of faster delivery and consistency in the schedule.

Fewer Clamping Operations & Higher Precision

This process reduces mistakes from re-aligning parts because its approach uses only a single clamping pattern. By closely overseeing key criteria in the production process, the error rate while machining is reduced.

Turning & Milling Capabilities for Complex Parts

Turn-mill machines can provide turning as well as milling abilities unlike a 5-axis machining center that can only accommodate milling. As all the processes are handled together, you can use advanced shapes that require less work arounds.

Ordering Process

Upload Your Design File

Submit your design file to initiate the process.

Choose Materials & Techniques

Select the materials for your product.

Instant Quotation & Ordering

Get a quote instantly and submit your order.

Precision Turning Taken Care

Leave the production to our capable hands.

Receive Your Item On Time

Get your finished item delivered to you.

We are trusted by many clients

Other sectors that use our precision turning services are automotive, aerospace, electronics and medical devices. We export our goods around the world and among the nations receiving them are the USA, Canada, the UK, France, Australia, Singapore and Malaysia. We are happy to collaborate with renowned companies like Tesla, Honda, Porsche and a few others.

Our Design Tips for Your Turned Parts

01

Avoid Long and Slender Parts

04

Select Machinable Materials

02

Simplify Complex Geometries

05

Maintain Consistent Wall Thickness

03

Incorporate Chamfers and Fillets

06

Ensure Adequate Clamping Surfaces

Note: While we can manufacture your parts to high standards even without following these design tips, adhering to our guidelines can help you minimize unnecessary costs and optimize production efficiency.