Learn all information about custom tooling, jig and fixture tooling in manufacturing, including how fixtures align . Find out about types, applications, advantages, design principles and forward trends on this 2700 word guide to precision manufacturing solutions.

Introduction to Jig and Fixture Tooling

The precision of manufacturing has been the key to any good production and jig and fixture tooling is one of the most important components towards precision, ensuring the correct position of various components . The use of these special purpose tools forms the basis of any modern day manufacturing venture which provides reliability and quality of the products; saves time i.e. less production cycle; and eliminates human error in an array of industrial undertakings.

Jigs are usually employed in drilling, boring, reaming and tapping jobs whereas fixtures are usually used in milling, slotting, shaping, turning and planning jobs. It is necessary to know the differences in the principles of operation and usage of these tools so that any manufacturing professional can streamline their production and ensure strictly adhered to quality values.

Understanding the Fundamental Differences Between Jigs and Fixtures

The difference between jigs and fixtures is the basis of good tooling strategy within a manufacturing setting. They both work in similar processes regarding workholding and positioning but the practical applications of them and the specific functions vary greatly.

The tools are instructed to jigs and the parts/ material to be worked on firmly in place by fixtures. This is the main difference between the two types of tools in the way they are formulated, mostly done, and applied in the fixture construction and manufacturing activities.

The Role of Jigs in Manufacturing Operations

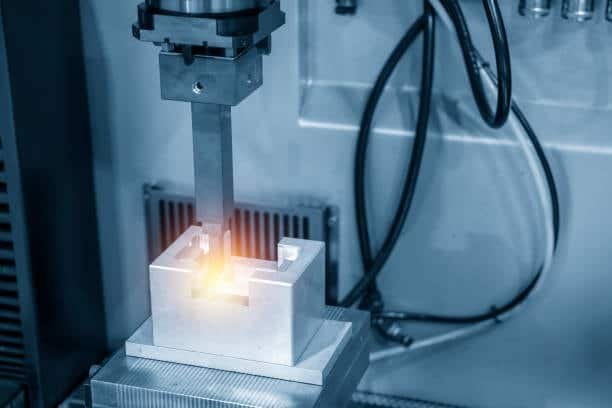

Jigs work as precision guides to the cutting tools in the process of machining with controlled movement and precise positioning features in the manufacturing facility. These devices come with inbuilt guidance which helps the cutting devices to cut in a manner that is exceedingly precise.

Jigs are special purpose implements that keep and govern motion of other tools and components when made throughout the production process, permitting more interchangeability and repetition. This is their advantage, and this is the reason they are necessary in high-volume producing set-ups to ensure consistency.

Fixture Applications and Industrial Implementation

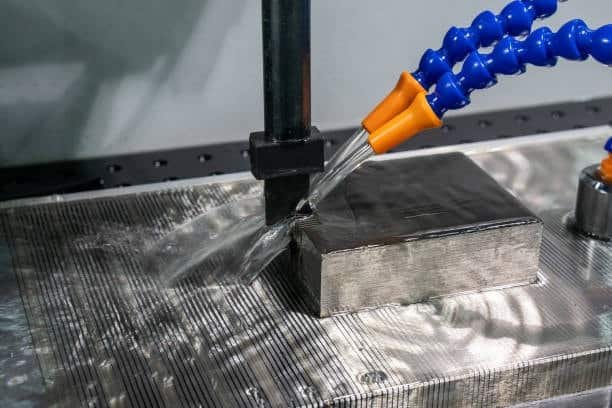

Fixtures are effective in work holding incidences in which the pieces are needed to stay firmly placed in place and held in distinctive positions as the machining processes are cared out. In sharp contrast to jigs, fixtures are more about workpiece support and less about tool guidance, offering the perfect solution to tasks needing high levels of cutting forces, particularly in managing welding stresses .

Under the robust design stands the strong assembly of fixtures, which respond to large mechanical loads, as well as ensuring their dimensional accuracy over long periods of the production cycle. This robustness has created great demand of the fixtures in heavy machining centres and in automated assembly lines, especially for mass production .

Types of Jigs Used in Modern Manufacturing

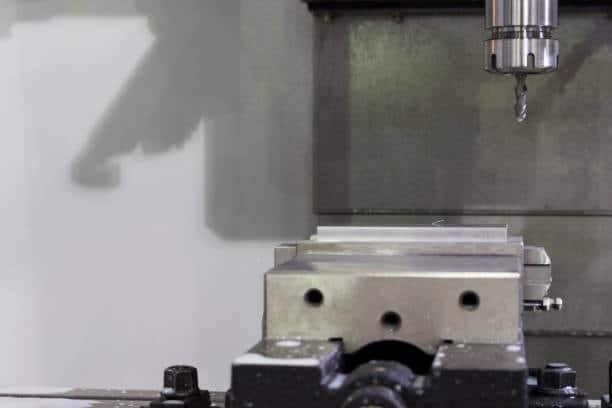

Depending on the applications and specific requirements to manufacturing operations, different types of jigs are identified. The most widely used are Drill jigs where carefully placed holes are necessary to direct drill bits to specific points on working pieces.

Boring jigs are guides to boring processes, and assembly jigs help in accurate components positioning in assembly processes. All the jig types involve special features and they are suited to bring the best jig performance and reliability on the activity they are intended to be performing, such as accurately positioning holes drilled .

Classification of Fixture Systems

Fixtures systems include a wide variety of configurations made to meet various types of work piece geometries and machining needs. Milling fixtures hold the work on milling machines and assembly fixtures give the work a secure support on the lathe machines, often utilizing mounting holes for enhanced stability .

Welding fixtures hold components at the right angle in most welding tasks and inspection fixtures guarantee quality control tests and measurements. This variety allows the manufacturers to choose the fixtures which fit their particular needs of operation.

Design Principles for Effective Jig Construction

The development of a successful jig involves paying a lot of attention to various aspects such as the geometry of the workpiece, machining forces, allowances with regard to tool access, and volume of production to be achieved. The design has to obtain the right balance between the aspects of functionality, durability, and cost-effectiveness, often incorporating toggle clamps for secure holding .

The main parts are the base or body which is where the work gets supported with some help of clamping elements to firmly hold the work In position. These basic designing principles derive the basis of any good jig construction.

Fixture Design Considerations and Best Practices

The requirement of fixture design includes detailed study of features of work pieces, machining activities, and manufacturing specifications. Efficient fixtures should meet work piece variations without altering positioning accuracy during the service life.

The role of choice of material, heat treatment needs and specifications of surface finish have great effects on the working of the fixtures and their life. Designers should critically consider these factors so as to ensure that the fixtures comply with short term needs and requirements of operations as well as long term production factors.

Materials and Manufacturing Methods for Jigs and Fixtures

Tool performance, durability and cost-effectiveness directly depend on the choice of the suitable materials to be used in constructing the jig andthe fixture. Traditional materials are tool steel, cast iron, and aluminum alloys, whereas each material has its own set of benefits regarding particular use.

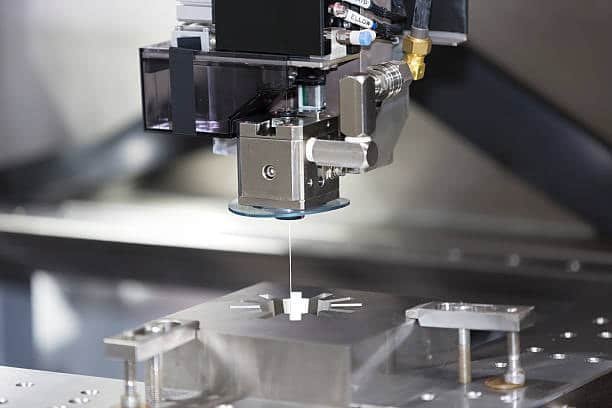

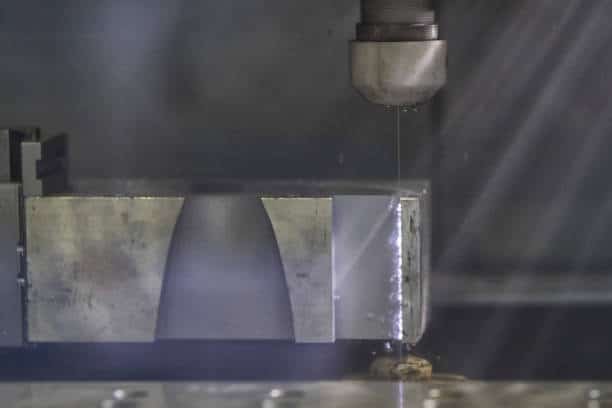

Cutting-edge manufacturing technologies, such as the use of CNC machining, EDM processing, and additive manufacturing, allow the manufacture of an even more complicated and accurate tooling solution. These technologies increase the capacities of design and shorten the lead time and cost of manufacturing.

Quality Control and Precision Standards

Ensuring high quality levels in all the processes of manufacturing jigs and fixtures means that these items perform consistently and the output of the manufacturing processes should be of the same quality. Dimensional accuracies, as well as geometric tolerances, are checked through precision measurement methods such as coordinate measuring machines and optical inspection system.

A systematic check up and calibration of tools maintains accuracy of tooling over long periods of servicing. These quality assurance techniques are required to ensure that the production remains consistent and that the expectations regarding quality by the customers are achieved.

Cost-Benefit Analysis of Jig and Fixture Implementation

Economics behind investments in jigs and fixtures are strongly dependent on volumes of production, quality demands and costs of labor. The upfront costs of tooling can be high but the benefits that occur across longer durations of use tend to offer an excellent return on the investment.

The price of jigs compared to fixtures tends to be more costly because of their more frequent complex design. Nevertheless, their accuracy and repeatability frequently compensate that extra expenditure, especially when they are used in larger-scale production facilities.

Integration with Automated Manufacturing Systems

The jigs and fixtures that are used today tend to be designed to easily integrate with the automated manufacturing systems. Actuators in the form of pneumatics and hydraulics allow workpiece clamping and release to happen automatically and feedback sensors give indication of workpiece position and clamping state.

This automation feature accelerates the performance in the reduction of the cycle time, the operator activity and improves the entire production performance. The combination of the smart tooling and manufacturing execution systems can give valuable information to manipulate the process and predictive maintenance initiatives.

Industry-Specific Applications and Requirements

Jigs and fixture design are unique to different industries in terms of their requirements applied to the products, according to the specific quality standards, and quantities per production, and the limitations applied to the operational processes of the company. Aerospace applications require traceability and exceptional precision, and automotive manufacturing is more focused on high-volume and repeatability, coupled with fast changeovers.

Biocompatible materials and documentation to validate the medical device manufacturing process, cost-effectiveness and versatility are the most desired with the general industrial applications. It is important to know these industry needs in producing the tooling successfully.

Maintenance and Longevity Strategies

The correct maintenance processes also add considerable length of service life to the jig fixture, jigs and fixtures maintaining their precision of operation. The presence of regular cleaning, lubricating, and checking procedures mean that excessive wear and tear do not take place, ensuring the correct orientation of the jigs and fixtures tapping fixtures.

The planned maintenance should be scheduled in terms of wear patterns, parts availability to replace, and upgrade options. This is a proactive tendency to reduce downtimes that are not predictable and to ensure a certain stability in the performances of the production tools during the tooling lifecycle broaching fixtures.

Dépannage des problèmes courants

The efficient troubleshooting steps help in finding quick solution to the jig and the fixture issue and safeguards the production to minimal disturbance and ensures the quality of the products. The most typical problems are that of excessive wear, dimensional drift, clamping issues, and components failures diameter jig.

Proper diagnosis methods are systematic with extensive paperwork and parts inventory, which make solving the problems fast and smooth. Maintenance staff training programs provide the reliable approach to troubleshooting and the ability to solve problems.

Future Trends in Jig and Fixture Technology

New technologies are transforming design and jig and fixture construction manufacture of jigs and fixtures. Additive manufacturing is becoming a technology that can offer complex geometries生Unexpected with traditional machining techniques, whereas smart sensors allow observed monitoring of tooling performance in real-time ring jig.

Small and medium-sized firms have been democratizing their access to precision tooling solutions to the creation of custom jigs, and fixtures using 3D printing, and enabling new designs to be prototyped quickly.

Digital Design and Simulation Tools

Digital Tools and Simulation Digital design and simulation tools are rapidly evolving to accommodate the complexity of design environments seen in practice. This is demonstrated by requirements to combine high-performance technology with increasingly high design abstraction fixturing elements.

Sophisticated CAD/CAM software packages offer the hi-tech technology of designing jigs and fixtures so that prototyping and simulation of the performance is made possible virtually by computer processes even before the physical manufacturing process. These digital technologies limit the number of iterations in designs, improve the functionality of the tooling, and make the development processes to be cheaper tooling plate.

Finite element analysis is the ability to test stress distribution, deflection patterns and thermal effects in the design process. This analytical capability secures the sufficiency of tooling and it also predicts possible chances of improvement prior to the commencement of manufacturing.

Rapid Prototyping and Additive Manufacturing

Additive manufacturing technologies have now made possible quick turn around in tooling and customization than ever before. Jigs and fixtures due to 3D printing do not take weeks but only few hours and product development is much faster and the time to market has become shorter fixed orientation.

Today, material advances in the additive manufacturing industry enable it to sustain production-level applications such as tooling, and high strength polymers as well as metal alloys are able to match traditional tool life. This has especially been useful in special engagements and low run production precise location.

Environmental Considerations and Sustainability

Increasingly, environmental awareness is bringing a sense of environmental design to decisions in jig and fixture design, as manufacturers are pursuing way to use materials sustainably and to approach energy-efficient production processes. Materials that can be recycled, less waste, and longer period of service will help performance in terms of the environment, particularly in processes like cylindrical grinding drill body.

Life cycle assessment approaches assists to assess the environmental implication of tooling choices, in regards to using of materials, end-of-life-disposal. Such analytical reports help to substantially make informed decisions and also show the corporate environmental responsibility.

Training and Skill Development Requirements

According to the professionals, they will help in the successful implementation of jig and fixture by undertaking extensive training programs in design, manufacturing, and maintaining personnel. Technical education incorporates concepts of design, manufacture, quality control and trouble shooting.

Lifelong training keeps staff at the edge with new technologies and practices that are best in the industry. Use of human capital development has a direct relation with tooling effectiveness and the production level of manufacturing machine spindle.

Economic Impact on Manufacturing Operations

Effective planning of jig and fixture tooling provides ample economic advantages by way of a higher productivity, high quality and lower labour costs drill bushes. These technologies help in the steady manufacture of complex parts with the lowest expertise requirement of machine operators.

Jigs and fixtures are employed to enhance the accuracy of manufacturing activities and thereby boost the uniformity and quality of the pieces. This development brings a direct change into the scrap levels, rework needs and satisfaction of customers tapered mandrels

.

Safety Considerations and Risk Management

The safety should be taken as the utmost issue in the jig and fixtures design and usage. Workpieces are clamped properly and are not ejected, and emergency stops and safety interlocks protect the operators and guard them against injuries broaching machines. Safe and comfortable functioning during prolonged manufacturing operations is guaranteed by ergonomics milling operations.

Assessment of risk identification games out certain risks and enacts any mitigation policies on the same boring fixtures. The awareness on safety requirements and the safe working practice is kept by regular safety audits and operator training curriculums such a way.

Global Supply Chain Considerations

Globalization in manufacturing demands jig and fixture designs that can support the range of requirements of different plants in terms of skills, maintenance options and quality manufacturing tools. Transfer of technology becomes easier with the standardized designs and documentation involved and this implies uniform performance in different parts of the globe grinding fixtures.

The resilience of supply chains substantiates material choice and supplier networks fixture plates. The tools effectiveness in global manufacturing centers is realized through local sourcing abilities, lead time needs as well as quality validation process template jig.

GWT Worldwide: Shenzhen Guanwutong International Freight Forwarding Co., Ltd. is one of the professional logistics service providers engaged in the global freight forwarding and supply chain business reduce labor costs. We provide efficient and affordable logistic solutions such as air freight, sea freight drilled holes, Railway transport of China-Europe, as well as shipping concept to Amazon FBA to worldwide plate jig.

Conclusion

Jig and fixtures tooling is itself one of the cone blocks of modern manufacturing excellence that allows manufacture of high-quality components at exceptional precision and leveling threaded holes. The practical application of these specialized tools produced quantitative results in terms of increasing productivity, quality and achieving cost reduction effectiveness of varying industrial applications radial holes.

Still, the Jig and Fixture technology industry is still gaining momentum toward a new generation of technology, which is enhanced by material science, manufacturing, and computer designs tool body. Companies open to such technological advancements by not losing their focus towards bare basic concepts of design will gain competitive results at ever-rising levels of demand in manufacturing drilling fixtures.