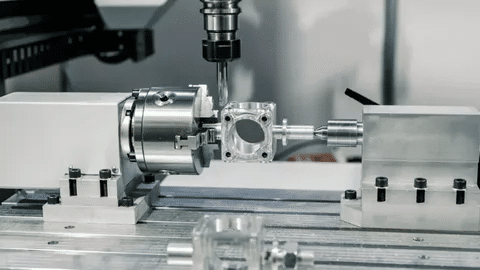

In our current competitive market of manufacturing, the CNC machining equipment you use will directly site an effect on how efficient, accurate, and profitable you manufacture your parts. Automotive connector machine parts, medical device parts or precision mold machine parts, regardless of the part you are trying to machine, tool selection is essential to meet the tight tolerances modern industries require.

What Are CNC Machining Tools?c9

CNC machining tools are cutter-like tools that are explicitly written with the aim of cutting off the pieces of work on computer numerically controlled (CNC) machines. These high-precision instruments cut up raw materials into finished parts with their different cutting processes consisting of drilling, milling, turning as well as threading. Unlike traditional hand tools CNC machining tools need to be able to operate at a high speed, be able to retain dimensional accuracy in the face of tremendous forces and consistently perform over thousands of machining cycles.

There are a number of factors that are important to the performance of CNC machining tools and they include the composition of the material, the technology used to paint the equipment and design of the geometry and accuracy of manufacturing. Good-quality tools generally are made of carbide or high-speed steel with wear resistant advanced coatings and with the cutting edges ground to a precise profile such that chip evacuation and surface finish are as good as possible.

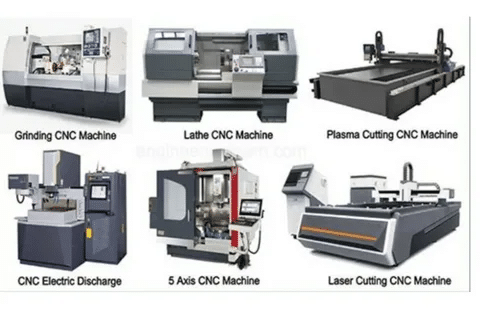

Categories of CNC Machining Tools

The CNC machining tools could be classified into a few functional groups where each group is apt to perform a given machining task:

The largest is the Cutting Tools which contains items such as end mills, drill bits, and face-mill, and actively cut material by a rotary cutting action. These are tools which have sharp cutting edges and are appropriate to use at high speeds with a very good chip evacuation ability.

Forming Tools shape pieces of work to certain shapes and profile, such as gear cutters, thread mills and profile mills. Their highly specialized tools are also necessary in the production of more complex geometrics that need some tight control in dimensions.

Finishing Tools Various types of reamers, boring tools and special inserts are aimed at creating high-surface finishes and close dimensions. Compared to other tools, the tools are usually relatively slow in their cutting rate but the level of accuracy and surface finishes that they provide is unparalleled.

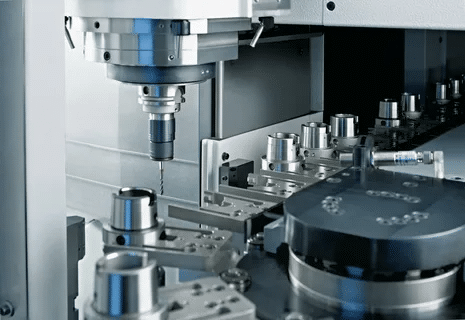

Holding and Support Tools such as the corresponding tool holder, collets, or workholding fixtures are used, when the product has to be positioned properly and acquire a stable position with respect to the tools during the machining process. Although not a direct contributor to cutting, these elements play key roles to ensuring accuracy and avoiding tool chatter.

Common CNC Machining Tools

Drill Bits

The most basic CNC tools are the drill bits that are used to execute cylindrical holes in different materials. CNC drill bitThe latest generation of CNC drill bits uses high end geometries designed with various point angles, flutes and coating systems that enhance their performance in specific materials and according to uses.

Carbide drill bits Carbide is often used to provide long tool life, especially with the hardened steels or abrasive materials. Point geometry has a large impact on drilling performance- standard 118-degree point geometry is best applied to general purpose hole, whereby 135-degree split-point geometry is applied when high centering is required and/or tunnel is to be drilled at higher production rates.

In punishing environments like deep hole drilling, where the material to be machined is hard to cut, drill bits of special construction with coolant delivery to the inside of the drill bit, helix angle variation, and coating solutions are available to produce excellent results and tool life.

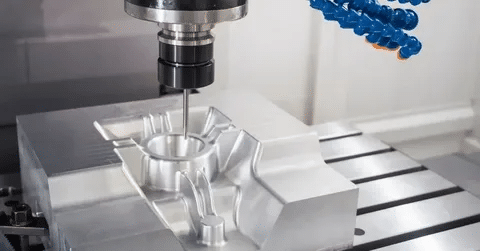

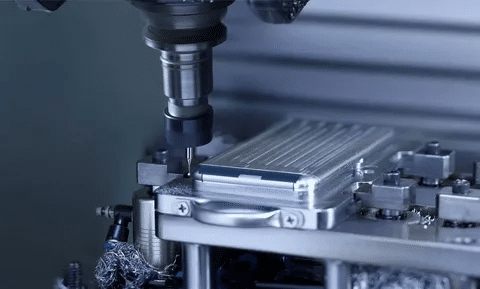

End Mills

One of the most flexible CNC machining tools is the end mill that can carry out face, peripheral milling, slotting and contouring operations. These tools have cutting edges on the end face and the cylindrical circumference so that complex three anatomy machining operations are possible.

Choosing end mill geometry really depends on what the application needs. Square end mills allow square corners during operations like slotting and facing whereas ball end mills are the champions in shaping three dimensionally and machining fillets. The length of corner radius end mill constitutes a trade-off of sharp corners and the strength of the tools, hence it is usable in general purpose machining.

High end mill product designs may involve adjusting the helix angles where chatter is an issue, uneven flute spacing to give a better finish, increasing or decreasing helix angle under the body of the end mill, and special coatings that enhance performance on certain materials like aluminum, stainless steel or hardened tools steels.

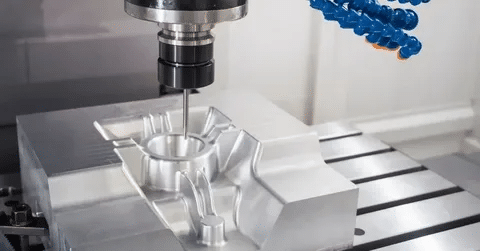

Face Mills

Face mills are cutters with a large diameter, they are mainly used in face milling and, in that scenario, the cutting edges move predominantly over the end face of the tool. These are ideal in removing large source of material in a short duration and also attaining quality of surface finish on broad workpieces.

Modern face mills are indexable insert-based, so that individual cutting edges can be changed as they wear down but still keep the rest of the tool body unchanged. In this method, the cost of tooling is minimized in a great extent without compromising the performance in a wide way. Insert types, grades and geometries may be chosen to give optimal performance in individual workpiece materials and machining conditions.

Face mills affect productivity and quality of surface finish directly through their diameter and insert setup. The greater diameter cutters allow higher metal to be removed and also the positioning of the inserts has been also optimized such that the chips are loaded equally and also the surface finish is good throughout the width of the cut.

Reamers

Reamers are honing tools which are used to create aggressive dimensional precision and good surface finishes on holes which have already been drilled. Such tools will at the most cut away 0.1-0.4mm of material, not concerned with the rate of material removal.

Machine reamers are straight or helical fluted used in CNC machining only. The geometry and cutting edge of the flutes are tune to particular materials and particular dimensions. Adjustable reamers permit a slight change in diameter, and thus these reamers would be useful to minimize tolerances during multiple production runs.

The type of reamer geometry is based on the application needs. Short holes – Straight-flute reamers offer the full rigidity. Helical-flute reamers are more chip-clearance oriented, and are appropriate in deep holes, and when interruptions of a cut are possible.

Taps and Dies

Taps and dies are rigged threading equipment, necessary in making internal and external threads in a CNC machining process. The modern CNC taps are more complicated, having superior geometries and coatings which can provide high rates of threading, and high quality threads with long tool life.

CNC machine taps are usually shorter chamfered with smarter flute design that allows faster thread cutting speed and does not affect the quality of the threads. Spiral flute taps are best suited to entering holes whereas spiral point taps are best suited to blind hole applications and evacuation of chips is very essential.

Thread mills are an alternative more developed than traditional taps and have more flexibility and provide the possibility of producing threads in hard materials. These tools can cut internal and external threads including accommodating thread pitch changes on a single tool.

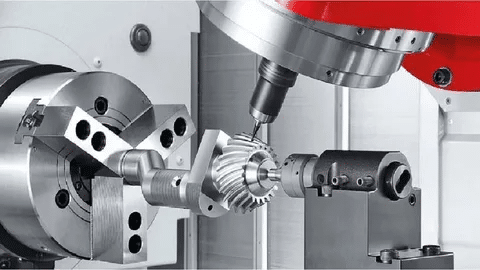

Gear Cutters

Gear cutters are a very special purpose tool use to create gear teeth and other complicated forms. High standards of precision and uniformity are very critical to these tools which must work with great accuracy since they are to be used to facilitate gear meshing in the completed product assembly.

Involute gear cutters make the exact shapes needed to produce typical gears, but custom gear cutters can also be designed such as to meet other specific requirements. The quality and performance of the finished gears are directly influenced by the accuracy of the gear cutters, so the quality and the accuracy of the tools are becoming a significant aspect.

The indexable insert technology has been an active part of modern gear cutting operations, which has enabled the cost effective production of high quality gears and the user the flexibility of cutting the parameter to suit the required gears.

Parting Tools

Cut-off tools (sometimes referred to as parting tools) are used to remove completed pieces out of bar stock or to produce large grooves on workpieces. Such tools have to resist high cutting forces and their dimensional accuracy and the quality of surface finish.

Parting tools are really dependent on their geometry in order to be functional. Tool binding can be avoided through proper side clearance, whereas the production of the chips and their evacuation is optimized by having the correct rake angle. Rigidity of tools is important in order to avoid deflection and chatter in the process of cutting.

Parting tool Modern parting tools are frequently made with more advanced grades and finishes of carbide that improve efficiency when cutting hard materials or at higher cutting speeds.

Broaches

Broaches are special cutting tools used to produce concentric internal profile, keyways and splines in a single cut. They are tools with several cutting teeth in a particular pattern in order to take up a gradual strip of material to give a desired profile.

Broaches have a very high application specific design, and the tooth geometry, pitch and progression is designed specifically to produce a given profile. Pull broaches are pulled through the workpiece and push broaches are pushed through and each design has some benefits of its advantageous uses.

Surface broaches produce external shapes, and they are often utilized to machining splines and keyways, or complex exterior contours. The high level of accuracy and finishing left by broaching operations normally removes the requirement of the finishing operations.

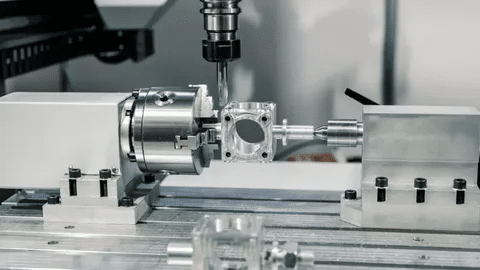

Boring Tools

Boring tools are intended to increase the sizes of the existing holes and keep their dimensional control accurate and acquire high surface finishes. These equipment will be necessary in the production of holes that are tight meaning that they cannot be manufactured using drilling process.

Single-point boring tools Also referred to as a single cutter tool: has only a single cutting edge, and can often be used with large holes or where great accuracy is needed. Advantages of multi-point boring tools Since these types of boring work with a greater number of cutting edges, they can also work faster with a material in the process compared to pressing individual cutting edges, as well as with multiple cutting edges.

Fine diameter adjustments can be made on adjustable boring tools, so they are useful where fine tolerances are required during productions runs. The stiffness of bored tool systems is essential in the prevention of chatter and to have a dimensional accuracy.

Inserts

Indexable inserts are a breakthrough to CNC tooling where there are replaceable cutting edges and this can save a lot of tooling costs in addition many inserts can be used to achieve consistent performance. These carbide or ceramic cutting elements are highly and accurately produced within close tolerances and they have sophisticated coatings.

Insert geometry is also specifically engineered to suit specific applications, with nose radius, preparation of cutting edges and design of chip breakers optimized to suit the requirements of a wide variety of materials and machining conditions. Time efficiency and time saving is available since the replacement of the worn inserts could be done in just a matter of minutes and therefore saving the machine downtimes and resulting in the quality of production being at all times.

The new technology of insert has highly specialized grades of insert to certain materials, enhanced coating systems to prolong tool life and small manufacturing tolerances which guarantee homogenous results on all cutting edges.

Tool Holders

Tool holders form an important interface between CNC machining tool and machine spindles and therefore proper positioning of tools, stiffness and runout control. Tool holder quality and accuracy directly affect accuracy of machining, surface finish and life of tools.

Tool holder system such as BT, CAT, HSK, and Capto have different advantages in regards to rigidity, accuracy and speed of tool change. Tool holder systems are selected based on machine specification, requirements of the application as well as desired performance characteristics.

Tool holders have precision fittings in tight runout tolerances with balanced forms allowing high-speed cutting with tough clamping systems that overcome the tool position with heavy cutting loads. The higher-priced tool-holders may be worth the cost in quality machining results, as well as tool-wear.

Custom CNC Machining Tools

Custom CNC machining tools suited to specific geometries, materials or manufacturing needs are required in many applications of precision manufacturing. Special tooling can help manufacturers to perform adequately in special applications in cases where mundane tooling cannot work.

CNC tool design and development process starts with thorough investigation of machining particulars such as the material and properties, geometrical tolerance, surface finish requirements and quantity of parts produced. This analysis is used in the design process of a tool so that designed tool can incorporate efficient performance by the end product.

The manufacturing of custom tools is demanding in terms of high-level grinding abilities, measurement precision systems as well as large-scale quality controls. Validations of custom tooling investments can often be noted by an increase in productivity, quality of parts being produced, and its overall cost to manufacture.

Choosing the Right CNC Tools for the Job

Depending upon the material of work pieces, dimensional specifications, surface finish specifications, and production quantity several factors should be taken into consideration when choosing a suitable CNC machining tool. Use of the wrong tool can lead to poor piece quality, remarkable wear on tools and even low rates of productivity.

Material Considerations are very important in selecting the tools. Aluminum needs other cutting edge shapes and coatings in contrast with hard steel or titanium alloys. Comprehending the nature of materials and how they are affected by tools is the key in selecting the best tool.

Parameters of Hu procurement such as cutting speed, feed rate, and the depth of cut need to correspond with capacities of tools and needs of workpieces. High-cutting parameters have the potential of enhancing productivity, although at the risk of affecting tool life or even the surface finish.

Quality Requirements such as dimensional tolerances and surface finish requirements actually affect tool selection. Tight tolerances might possibly call for uniquely finish tools or even a serious number of machining tasks utilizing dissimilar tool sorts.

The use of specialized tooling is also influenced by consideration of lower Production Volumes It becomes less economical to use specialized tooling at low volumes. Large quantity manufacture can support the investment in special tools or high-quality grades of tools whereas small-scale usage can be more suited with standard tooling packages.

Conclusion

Identification and use of the right CNC machining tools are at the core of the success of the contemporary precision manufacturing. Electric drills to advanced custom tooling products, every type of tool in your arsenal has a particular niche in the complete machining procedure.

Being aware of the ability of the various types of tools and their shortcomings, manufacturers will have an informed decision making process that ensures maximum productivity, quality and cost effectivity. The level of investment in good tooling as well as expertise to use the tooling well is what makes the difference between a profitable and a struggling manufacturing operation.

With manufacturing changing its demands to increasingly stricter tolerances, better surface finish and increased geometries, advanced CNC machining tools are becoming more and more important. In the modern competitive manufacturing business where most industries are highly demanding, it is of paramount importance to keep up-to-date with the best practice of the tooling technology in order to maintain a competitive advantage.