Two-Shot Injection Molding Services | Worldwide Solutions

Two Colors in One Cycle with Two-Shot Injection Molding

- Simultaneous Injection Molding of Two Different Colors or Materials

- A Variety of Processes with the Best Dual-Color Injection Molding Machine

An NDA can be signed if needed before the quotation.

Two-Color or Dual-Material Plastic Parts Solution

Dual-shot, two-shot or multi-shot molding is the process where two different types of plastic are processed at the same time. Even though it is commonly believed that two-shot moulding is tougher, slower and costlier than some other plastic moulding methods, deciding to work with zcmould proves that there are more benefits to the process.

We treat problem solving as our main mission, instead of only making things. Cooperating closely with all our partners, we frequently assess and enhance how safe, effective and high-quality our products are. Our customers enjoy quality components at fairly affordable market prices for their two-shot moulding projects.

- Reduce Your Manufacturing Costs

- Achieve Quicker Production Times

- Optimize Co-polymerization Between Materials

Orders Workflow

Consultation & Analysis

Share your requirements with us and our qualified team will guide you as an individual.

Engineering and Design

In partnership with you, our knowledgeable engineers design a detailed strategy that carefully addresses every element at each step during your two-part component’s creation.

Designing Tools and Testing Models

When the design phase ends, the following phase is tooling and prototyping. At this point, designers use advanced tools for CAD/CAM and 3D printing to build accurate moulds and first models for testing and approval.

Manufacturing

We start making two-shot moulds after preparing the moulding tools. The use of precise injections of selected materials creates the final dual-component parts that are always accurate and consistent.

Ensuring High Standards

All products are checked for quality with visual inspection, measurements and using them to confirm they meet your requirements.

Shipping and Packaging

We package your dual-component items properly for delivery and we will label and brand them upon your request. When you rely on our service, your car parts will be delivered as planned without any issues.

zcmould’s Advantages

Why Choose zcmould for Two-Shot Molding?

- Improved product appeal

- Fulfilled complex designs

- Enhanced grip on non-slip surfaces

- Capable of extra functions

- Stronger and more durable

- Wide applications

Advanced two-shot machines

With four high-quality two-shot injection machines at our workshop, we can supply low-cost and fast services for mass production.

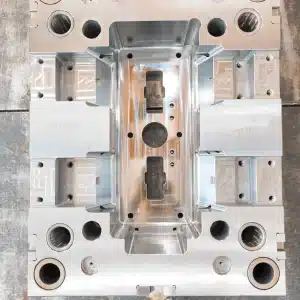

Two-shot mold development capability

From our fabrication workshop, we can make accurately shaped two-shot moulds.

Create with Dual Precision With A Click

Benefits of Our Two-Shot Molding Service

Complex Design Capabilities

We always stay in communication with our clients, collect their ideas and work on the design to meet all the requirements. All we want is every project to be completed.

Complex Design Capabilities

Initially, we consider dual-color moulds to be precision engineering and promise they achieve the maximum level of accuracy in making choices about materials, designing, processing and so on.

Complex Design Capabilities

Using a variety of materials results in parts that have seals, soft-touch grips and ergonomic handles which improve how users experience the product.

Complex Design Capabilities

Two-shot moulding gives us many chances to explore new design ideas. If you use detailed combining of patterns, textures and gradients of color, your product will look better and have more value.

Complex Design Capabilities

Even though two-shot moulding appears more expensive at the start, it saves money because it causes less waste and makes production more efficient.

Expertise in Plastic Material Co-Polymerization

Polymers each have specific traits in terms of their physical and chemical makeup. We have gained a lot of experience in co-polymerizing different types of materials over ten years. It allows our team to use all the options your products have to make them inviting and appealing.

- Consider the compatibility of the two plastics

- Consider the difference in shrinkage rate between the two plastics

- Consider the complexity of the shape of the molded produc