What is Metal Removal Rate: The Complete Guide to Understanding MRR in Machining

The material removal rate (MRR) refers to the quantity of material eliminated in one minute of machining as it is

The material removal rate (MRR) refers to the quantity of material eliminated in one minute of machining as it is

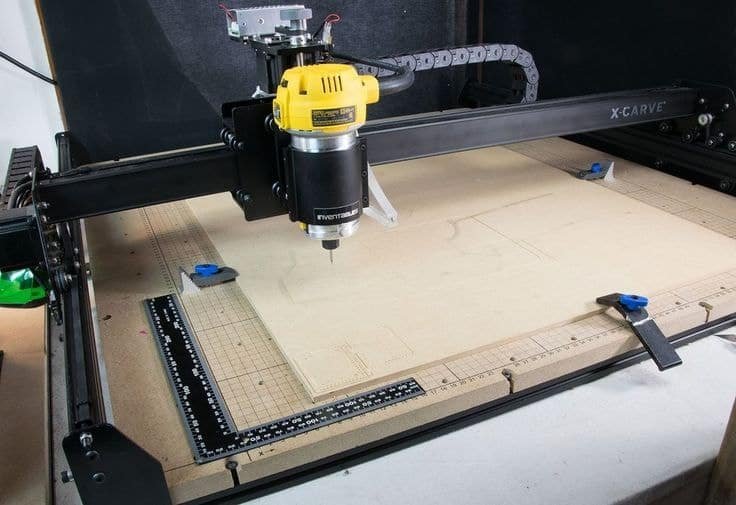

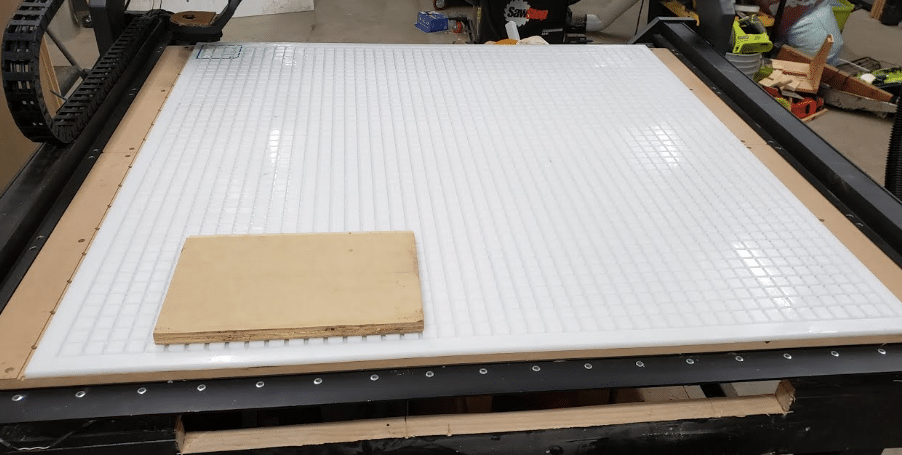

CNC router workholding consists of a variety of techniques of workholding, many of them in use since the dawn of

Swiss machining is an excellently developed precision manufacturing technology that can never be matched in terms of accuracy and efficiency

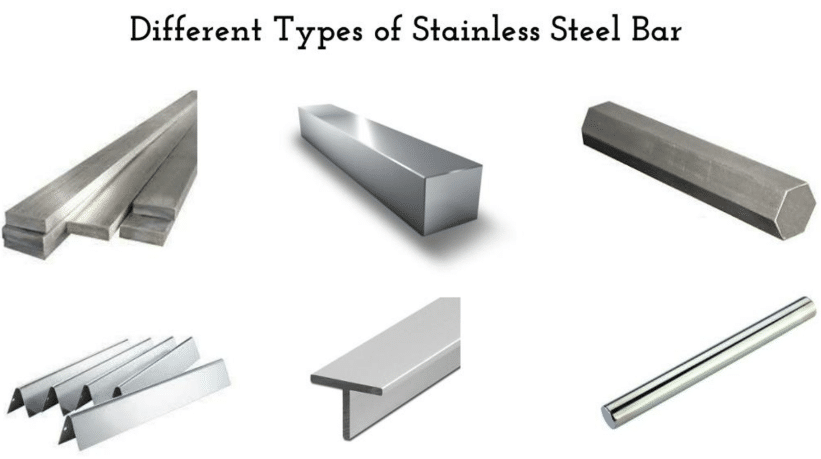

This guide discusses the five general stainless steel families: austenitic (was commonly 304 and 316), ferritic (was commonly 430 and

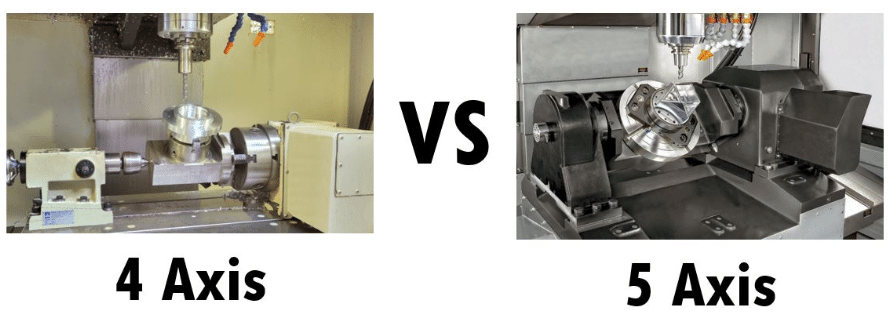

The multi-axis machining technology has been a game-changer in precision manufacturing as it has gone beyond the traditional 3-axis imposed

To conclude, 3-axis CNC milling is most suitable to simple, flat designs and 4-axis milling exists in complex, rotational configurations.

The knowledge about the differences between copper and bronze colors can facilitate the adequate decision-making in the vast variety of

Chrome metal is a very important industry foundation material with very useful properties such as resistance to corrosion, wear and

One of the best and cheapest options to consider in increasing the efficiency and sense of precision of your CNC

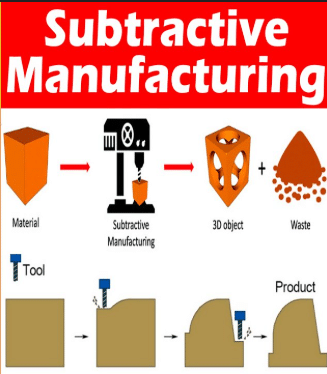

The subtractive method of manufacturing is an extremely crucial production technique, where no preciseness and use of material in industries

WhatsAppはこちら