Meta Description: what are the applications of 3-axis, 4-axis, and 5 axis machining CNC milling and 4 axis cnc machining, including the use of rotary axis, , including their rotation axes, what are their limitations and advantages? Get to know which is the best machining process to use in your manufacturing process.

Introduction to CNC Machining

CNC machining has transformed the way manufacturing is done and has made the production of complex parts easy, accurate and automated. The three axes, 4-axis milling, and 5 axis cnc machining are some of the most popular CNC machining processes that cut across several sectors such as automotive, aerospace, and others. Though both techniques provide very precise results and high precision, understanding part geometry is crucial. , they have different applications, capabilities, and complexity. This knowledge is important to help you in ranking the appropriate machining process to use in your project.

This blog will discuss main differences between 3-axis and 4-axis CNC milling, cutting tool movement, and 5 axis machining, their pros, cons and in which situations these are applicable. This guide will assist you in an in depth decision process whether you are a manufacturer, engineer or a hobbyist.

What Is 3-Axis CNC Milling?

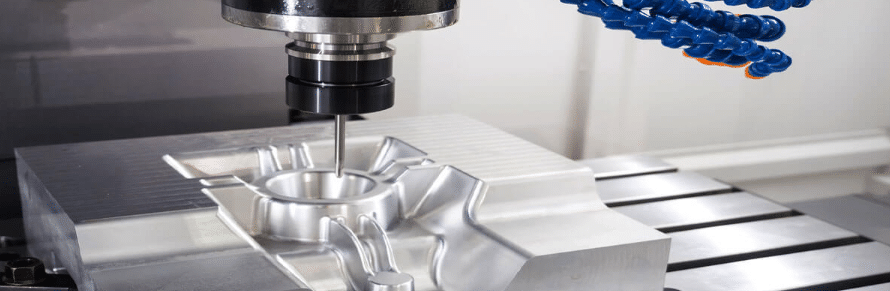

The 3-axis CNC milling follows 3 lines, X, Y, and Z. The cutting tool is in motion and in these three directions the cutting tool transforms the workpiece by effectively processing the cutting material . The process suits simple or flat or rectangular components that need simple machining, while in more advanced setups, the workpiece rotates .

3-axis milling is commonly practiced in simple industrial work where simplicity is low like making of brackets, housings, among other simple structure works. It is economical and therefore efficient in high volume production of identical parts because of its simplicity. Nonetheless, it cannot machine tricky geometries and angled features is therefore not appropriate in designs with more complex geometries.

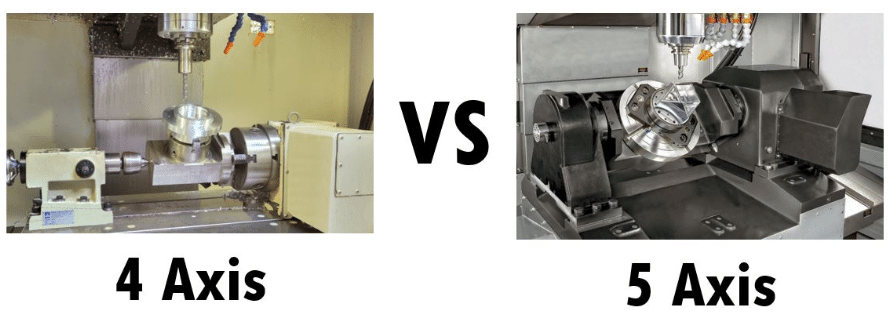

What Is 4-Axis CNC Milling?

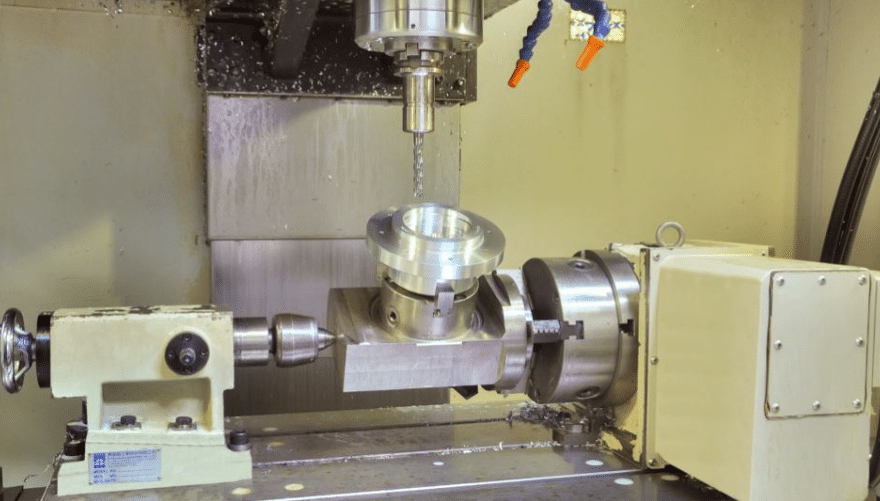

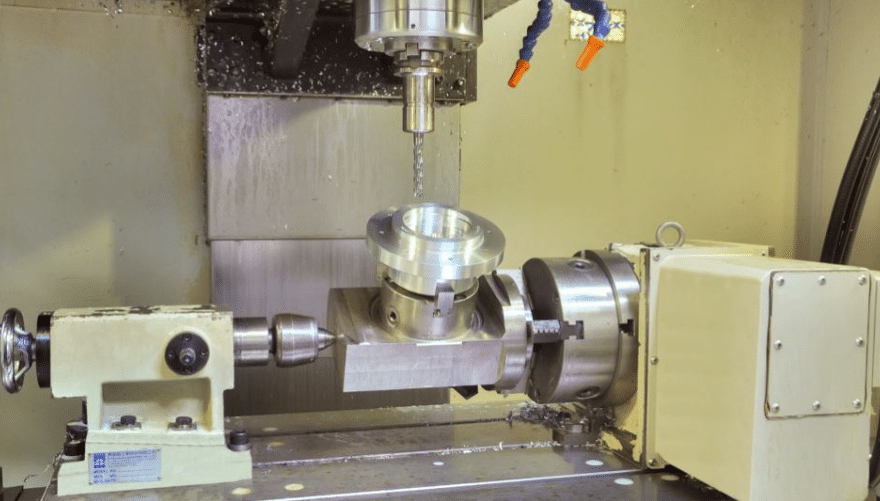

4-axis CNC milling has one more rotational axis ( A or B ) instead of the X, Y and z. The last rotary table axis, known as the a axis, is the one that permits movement so that the workpiece can rotate around the single axis, thus making it able to perform more complex machining operations. This can be rotated about the X-axis (A-axis), about the Y-axis (B-axis), depending on the design of the machine.

The process is especially applicable in the problemywing of turning cylindrical or angular components, including turbine blades, gearing-and impellers, due to the additional axis that enhances its capabilitie . The new rotational capacity increases the speed of set up and reduces the need for multiple setups, thus allowing better surface finish and tighter tolerances s there is no time lag in changing the place of the workpiece during cutting. Compared with the 3-axis milling, the 4-axis machining is more closed in terms of the requirements of complex programming and the greater cost of the machines.

Key Differences Between 3-Axis and 4-Axis CNC Milling

These main dissimilarities between the 3-axes CNC milling and the 4-axes CNC milling include the movement, complexity, and their ability to machine multiple sides. A comparison is given below in detail:

Movement & Flexibility:

- 3-Axis: Only linear movements on X, Y and Z.

- 4-Axis: It provides the rotational movement and enables the more challenging geometry of parts.

Setup & Efficiency:

- 3-Axis: Complex parts require many setups, which prolong the production time.

- 4-Axis: Helps save time when it comes to the set up of the machine as there is no interruption when 4-axis is used.

Cost & Complexity:

- 3-axis: Able to be programmed more simply and cheaply.

- 4-Axis: Costs more and more complicated programming.

Applications:

- 3-Axis: Ideal in easy and flat components such as plates, and frames.

- 4-Axis: It is applicable on cylinder, angular and complex pieces.

Advantages of 3-Axis CNC Milling

CNC milling 3-Axis and 3 axis cnc machining machines is still a favored option for producing precision parts because it has become a simple and affordable mode of use. The main benefits are the following:

- Lower Price: 3-axis machines are cheaper to buy as well as maintain.

- Simple: Simple to program and easy to operate which makes it affordable to small to medium business enterprises.

- Higher Efficiency on Easy Parts: Best suited to mass production of components which are not very complex.

- Increased coverage: They are more prevalent in the workshops, which guarantee this aspect of easier access to services.

It is, however, not quite appropriate to advanced manufacturing demands due to its shortcomings in the input of complex-shaped objects.

Advantages of 4-Axis CNC Milling

4-axis CNC milling is more flexible and precise, and these features make it applicable in more challenging applications, including those requiring threaded holes in line. Such advantages are:

- Less Setup Time: The rotational axis limits the repositioning and therefore saves time.

- Better Surface Finish: There is reduction of tool marks and part quality is improved with continuous cutting.

- Ability to handle complex components: Perfect to make cylindrical, angular, and asymmetrical parts z axis.

- Higher Efficiency: Reduced machining processes translate to the quickening of production processes.

Although these are the advantages, 4-axis milling needs operators who have skills and also needs high CAM software thus leading to high cost of operation cnc milling machines.

Applications of 3-Axis vs. 4-Axis CNC Milling

Decision to use either 3-axis milling or 4-axis milling is determined by the complexity of the part, including factors like threaded holes and what industry requirements linear directions.

3-Axis Applications:

- Brackets, frames (automotive)

- Electronics (printed circuit boards, housings)

- Furniture (custom paneling, fittings)

- Low volume manufacture and prototyping

4-Axis Applications:

- Aerospace (blades, impellers, turbines)

- Medical equipment (equipment used in surgery, implants)

- complex cavities Mold and die making planar milled profiles

- Car (gears, engine parts)

Choosing Between 3-Axis and 4-Axis CNC Milling

The choice of the machining process requires a number of considerations c axis:

Part Complexity:

- Put simple, flat parts on 3-axis both the workpiece

- Use a 4-axis to cylindrical or angular shapes.

Production Volume:

- 3-axis is superior to the high-volume, plain parts.

- 4-axis offers low to medium volume.

Budget:

- 3-axis offers a better price that is friendly to the budget minded projects.

- The 4-axis is more expensive to invest in but is more versatile horizontal plane.

Time Constraints:

- In complex parts, 3-axis may prove to be time consuming because of the numerous set-ups.

- 4-axis makes production faster as it continues to produce uninterrupted.

結論

Three axis and 4-axis CNC milling have both their own advantages and drawbacks. Although 3-axis milling is efficient and cost-effective as far as simple parts are concerned, 4-axis milling is more flexible when it comes to complex parts. Knowing their differences, especially in multi axis machining, can help the manufacturers to be able to choose the correct process so as to maximize efficiency of production, lower costs, and improve the quality of the part.

Note: Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) is a professional logistics service provider, which focuses on global freight forwarding service, supply chain services, and cross-border e-Commerce logistics. Having a good market in both China and the global markets, we are determined to provide effective, standardized, and tailor-made logistics services to companies across the world. To name a few, our core services encompass air freight, se freight, China-Europe railway transportation, international express & courier services, customs clearance and warehousing, as well as shipping and labeling support of Amazon FBA online stores. In GWT Worldwide our approach is efficiency, clarity and customer satisfaction. Through sophisticated logistics tech and a worldwide chain of credible partners, we take care that your commodities are safely, promptly and, and compliantly transported across the arteries between origin and destiny. As a small business or a large-scale importer/exporter, GWT Worldwide will be your reliable logistic partner through whom you are sure of your smooth international business.