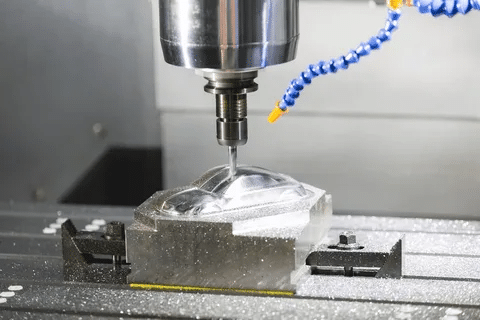

It is important to have knowledge in CNC machining costs which would enable manufacturers to make optimum use of their production budget with or without compromising the quality of production. You can custom-develop the mold used to make automotive connectors, or precision medical parts, or design and machine semiconductor packaging parts and having a working knowledge of how to estimate the cost of machining and manage these costs can have a material bottom line impact as well. Here is a guide to the CNC milling costs that will show you the costs in detail including simple pricing to more complex cost-saving measures.

How Much Does CNC Milling Cost?

The costs involved in CNC milling are normally between 35 to 200 dollars an hour depending on the complexity of the machine, type of material used as well as the preciseness of the machine. On a section-by-section basis individual costs may range as low as 10 dollars per entry for simple elements to several thousand dollars per entry on complex high precision elements that meet special material requirements such as in tungsten steel or other exotic alloys.

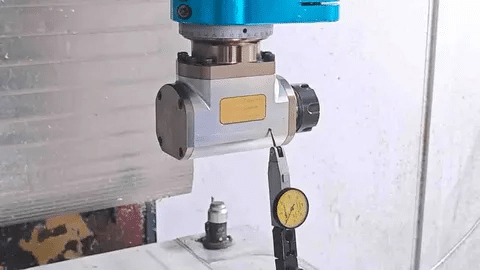

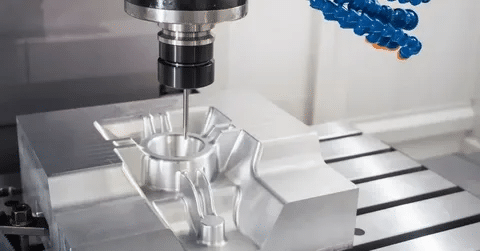

The large variance of prices affirms the varying nature and varieties of CNC operations, where a basic 3-axis milling of aluminum machine aluminum prototypes is a simple job compared to a more complex 5-axis routing on aerospace grade titanium parts. The majority of precision mold makers fall in the range of between 75-150 dollars an hour and specialty work fetches extra high prices on ultra high precision where tolerances of better than 0.001 of a millimeter can be achieved.

Factors That Affect CNC Milling Costs

Material Costs

The type of material greatly influences the general costs of machining, making it as high as 20-40 percent of the total amount. The typical materials and their cost implications relative include:

- Aluminum alloys: They are economical and simply machined and little tool wear is needed

- Kinds of steel: Medium pricing and machinability character which differs with hardness and alloying elements of the metal

- Stainless steel: Greater costs of materials, and greater wear on tools because of work hardening tendencies

- Titanium: High quality technology that needs special tooling and needs lower cutting rates

- Exotic alloys: such as Inconel, Hastelloy, etc, they require specialized knowledge and equipment.

Design Complexity

Any complex geometry or tolerances and details are proportionally related to the costs and time of machining. Simple rectangular components with standard tolerances (dimension of 0.005 mm) are much cheaper as compared to components that need:

- Various arrangements and fixtures alterations

- Big holes or hollow corners

- Multi-sided 3-dimensional features which need 5-axis machining

- Tolerance of less than +/-0.002mm

- Special surface finish (Ra 0.025 or it should be better)

Quantity

Economies of scale are provided by the volume of the production and significantly influence the costs of one part. Fixed costs are associated with the setup time, programming and preparation of the tooling and are then spread over the runs of production:

- Prototype/Low volume (1-10 parts): Cost Ignorant costs too high because set up schedule high (per-part)

- Medium volume (10-100 parts): Medium per-part prices and partial amortization of setup cost

- High volume (100+ parts): Minimum costs per-part due to maximum setup costs shared

Labor Costs

A talented CNC machinist earns high wages especially when his skills are required in precision work which necessitates mastery over:

- Complex piece fit up and workholding

- Selection and optimization of tools

- Measurement and quality in-process control

- Solving and trouble shooting in production

Overhead Costs

Some of the manufacturing overheads involve cost of manufacturing facilities, depreciation of equipment, utilities costs, quality systems and administration costs. These are costs that normally augment with 150-300% on direct labor costs, which depends on:

- Size and location of facilities

- Sophistication of the equipment and maintenance needs

- Expenses of quality certifications ( ISO9001, AS9100, and so on )

- Insurance and regulatory RSA costs

Cost of Different Materials for CNC Milling

The price of material depends very much on availability, machinability and application demands:

Aluminum Alloys (6061, 7075)

- Price of materials: 3-8 dollars/lb.

- Machining properties: Very good machinability, low tool consumption

- Common uses: Prototypes, aerospace parts, consumer products

Carbon Steel (1018, 1045)

- The cost of materials: 1-3 dollars per pound

- Machining traits: No special machinability, fair tool wear

- Assemblies: General Manufacturing Applications, Tooling, Structural Components

Stainless Steel (304, 316)

- The cost of material: 4-12 dollars per one pound

- Machining properties: Hard to machine because of work hardening, more tool wear

- General applications: Medical applications, food applications, corrosion resistant parts

Tool Steel (H13, P20)

- Price of materials: 8-25 dollars a pound

- Matters of machining: Hard to machine, needs special tools

- Standard uses: Injection molding parts, die-casting dies

Titanium (Grade 2, Grade 5)

- Cost of the material: 15-50 dollars a weight per pound

- Machining details: Hard to machine, requires special coolant and special tooling

- Typical uses: space, bio-medical implants high performance applications

CNC Machining Cost Calculation: Per Hour vs Per Part

Knowledge of the pricing models enables manufacturers to select the most efficient one in terms of their peculiarities:

Hourly Rate Model

- Suitable to: Prototyping, product development, small-scale production

- Benefits: Clear costing, applicable to loosely-defined project scope

- Normal prices: Between 75-150/hour depending on careful work

- Considerations: Time estimates need to be precise so that budget can be planned

Per-Part Pricing Model

- Most suitable: when runs are needed, a repeat order is needed, there are clear specifications

- Pros: Easy to predict costs, no complicated procurement

- Factors of calculation: material, set up time, machining time, finishing operations

- Considerations: Part analysis is intricate to quote fairly

Hybrid Approach Many precision manufacturers use combination pricing:

- Programming and fixturing set ups costs

- Production run costs Per-part

- Time based cost of any change or consulting work

How to Reduce CNC Milling Costs

The manufacturing costs can be reduced substantially with methods concerning cost reduction with no reduction on quality:

Design Optimization

- Reduce geometries where possible

- Standard hole size and standard tooling

- Reduce the amount of setups involved

- Be realistic with tolerances (do not over specify)

- Just reflect about the requirements of surface finish

素材の選択

- Use materials that are corresponding to real performance requirements

- Look at other alloys that are similar in the properties but more machinable

- Increase efficiencies in use of materials to ensure the wastage is limited

- Review availability material/lead times

Production Planning

- Integrate like components in one systems

- Produce with shorter run and few setups

- Look at tooling the family of components

- Cutting parameters optimization

Quality Management

- Install first-piece inspection to avoid making scrap

- Apply statistical process control in order to be consistent

- Locate inspections points sanely

- Practice Traceability by having proper records

CNC Milling Cost Calculator

Estimating CNC milling costs requires consideration of multiple variables:

Basic Cost Formula: Total Cost = (Material Cost + Setup Cost + Machining Time × Hourly Rate + Finishing Operations + Overhead) × Profit Margin

Key Variables:

- Price/material volume cost spoilage/unit

- To set up (An average of 1 to 4 hours)

- Cutting parameters (Calculated value of machining time)

- Shop rate (per hour): ($75150)

- 9. Overhead multiplier (1.5-3.0)

- Profit margin (15-30 percent)

Online Tools and Software: a number of manufacturers have online cost calculators, however it is always necessary to obtain actual quotes when assessing production plans. These tools give approximate values so as to make budgets.

CNC Milling: Cost vs Other Manufacturing Technologies

Comparing CNC milling costs with alternative manufacturing methods helps determine the most cost-effective approach:

射出成形

- Lower per-part costs for high volumes (10,000+ parts)

- High upfront tooling costs ($20,000-200,000)

- Best for: High-volume production of plastic parts

- Crossover point: Typically 1,000-10,000 parts depending on complexity

3Dプリント

- Lower setup costs, higher per-part costs

- Material limitations and surface finish considerations

- Best for: Prototyping, low-volume production, complex geometries

- Crossover point: Typically 1-100 parts depending on size and material

Stamping/Forming

- Very low per-part costs for high volumes

- Moderate to high tooling costs

- Best for: Sheet metal parts, high-volume production

- Crossover point: Typically 1,000-5,000 parts

Manual Machining

- Higher labor costs, lower equipment costs

- Suitable for one-off parts or very low volumes

- Best for: Prototypes, repairs, modifications

- Crossover point: Typically 1-10 parts

Get a Quote from Zecheng Precision Today

In Dongguan Zecheng Precision Mold Co., Ltd., we realize that being able to always predict your costs is of great importance to your manufacturing success. Advanced Japanese production machinery and experience of decades, help us to offer competitive prices, at the same time we maintain our precision levels of dimension accuracy to ±0.001 mm.

Extended quoting process:

- advanced DFM (Design for Manufacturing) studies

- The recommendations of material optimization

- Cost effective production planning

- Quality planning assurance

- Management of delivery time lines

Regardless of whether you require automotive connector molds, precision parts of medical devices, or semiconductor packaging components, our group can offer transparent and competitive prices due to our policy of quality and on-time delivery. We have the global experience of serving clients in Germany, United States, Japan, Italy, Singapore, Thailand and Malaysia hence we are aware of the various market needs and cost pressure.

Inquire with our engineering department now, to receive a specific quote on your precision machining needs. We also offer full cost analysis, substitute material recommendations, and optimization suggestions concerning the production so that you can have quality outputs within budget constraints.

結論

The cost of CNC machining is determined by a number of factors that are dependent on each other, involving the choice of material, complexity of the design, quantities, and precision project demands. The insight about these variables can help the manufacturers make responsible decisions that can strike the balance between cost and quality requirements.

Importantly, the most cost-efficient CNC machining depends on the early involvement of manufacturers that will be able to suggest the optimization of the design, material choice, production plan, etc. Manufacturers afford to save a lot of money on production costs in relation to the cutting of tolerances, how well the surface is treated and production targets, when a particular design is taken into consideration.

CNC machining in the modern world is characterized by a level of precision and flexibility that is unmatched in other forms of machining, and thus, it is a great application when high tolerances and complex geometries (or even materials) are required. Although the cost could be varied broadly depending upon the requirements, the cost incurred in precision machining can be beneficial in terms of better performance of the product, lower cost of assembly and better competitiveness in the market.