Meta Description: Interested in creating a DIY CNC vacuum table? This 1600-word guide will explain to you how to create one, using materials commonly found at a hardware store . Learn the materials, step-by-step guidelines, as well as techniques of constructing the cost effective vacuum hold-down system to your CNC router to achieve the precision and efficiency of work.

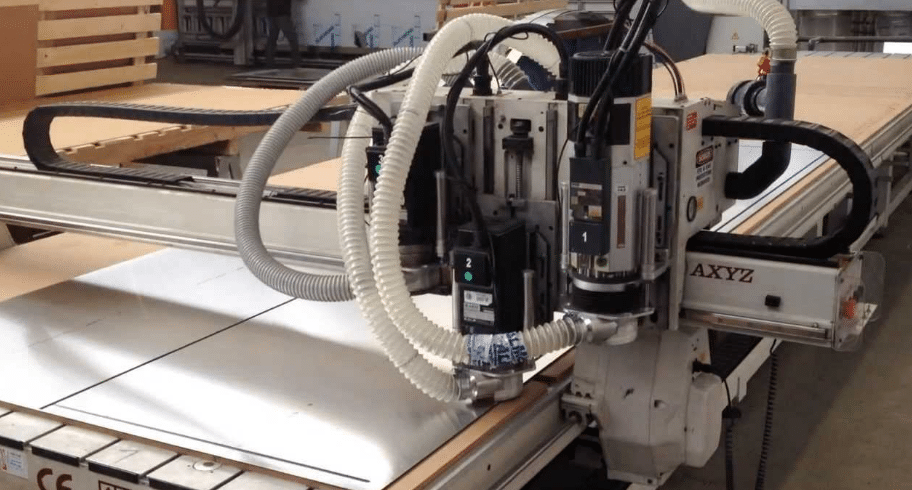

CNC routers are highly capable both to the hobbyist and professional bearing in mind that sometimes work holding is a task. A vacuum table is a good, easy solution of estimating materials without taping or clamps, and this method allows you to become more efficient and precise. This manual gives a precise, tutorial development of DIY CNC table vacuum, which is entailed in its materials, including, but not limited to, websites such as OpenBuilds and Instructables. A vacuum table can make your work process efficient whether you are milling wood, aluminum, or any other flat-type material. Also, to the business that imports materials abroad, there are service providers, such as Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide), that offer logistics services of freighting air and sea, customs declaration and Amazon FBA shipment, so that you should receive your supplies effectively.

Understanding the Basics of a CNC Vacuum Table

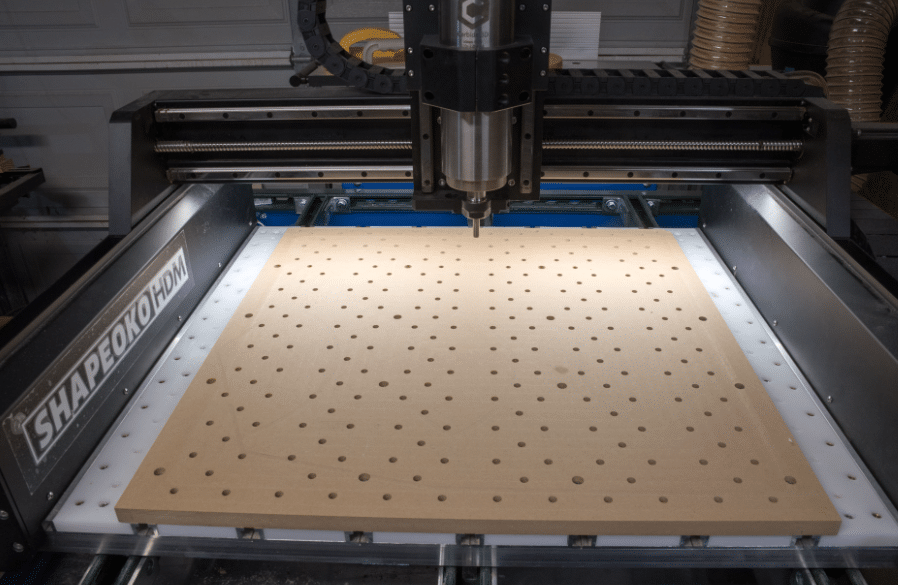

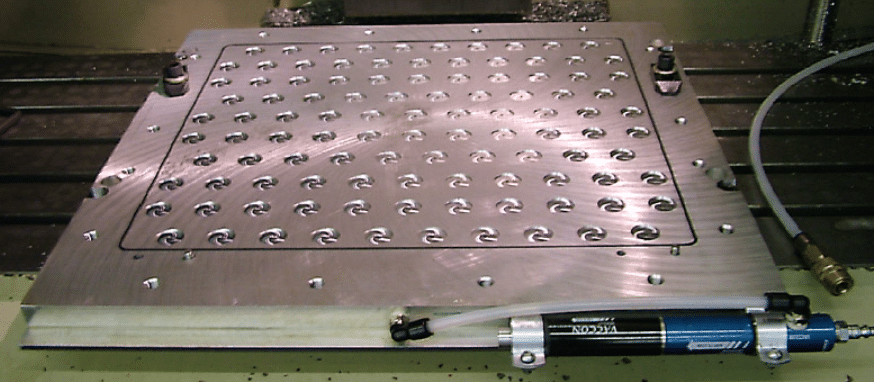

Mechanical clamps are unnecessary because a work piece on a CNC vacuum table is fixed to a working surface by means of aspiration, creating a pressure that holds the workpiece firmly in place . The table will have a base, a plenum where there are channels of air and a porous spoilboard to provide even suction. The suction comes in the form of a vacuum pump or shop vac that is used to pull air through the surface of the table to give the grasp. This is the best option with flat materials such as plywood, MDF or aluminum sheets since very little post-processing is needed and has the fastest setup. The four main parts of the system are the base, plenum, spoilboard, and the vacuum source, knowing which parts you are going to be building a layout that will perfectly fit your CNC router and its requirements..

Benefits of a DIY CNC Vacuum Table

There are a few benefits of making your own vacuum table. To begin with, it is an economical venture as opposed to commercial forms that cost thousands of dollars, which often do not accommodate the weight of heavy material . An OpenBuilds description of a DIY system is designed to fit a typical 6hp workshop vacuum, and as such can be easily fitted by a hobbyist. Second, it also time-saving, as clamps or tape are not required to be used, which is time-consuming and damaging to materials. Third, a vacuum table supplements accuracy by making the work piece flat and stable in the course of cutting it. Lastly, the table can be modified to suit your CNC size so that it can be used in many ways, ensuring a good seal for efficiency. like adding a zoned area on a 4×8-foot table that will allow use in many different ways as shown in the OpenBuilds build.

Materials Needed for Your DIY Vacuum Table

In order to build a vacuum table, take the following materials, including the inlet for the vacuum system, where a hole will be cut for the vacuum pipe. spired by the Open Builds and Instructible tutorials:

- Base Board: dia. 18mm Baltic birch plywood oder MDF (sealed against air leaks).

- Plenum Board: Airflow channels: MDF or high-density plastic.

- Spoilboard: Vacuum distribution (e.g., Porous MDF, e.g., Trupan Ultralite).

- Vaccum Source: 6hp canister vacuum or shop vac (filter and bag taken out to give a vacuum as much suction as possible).

- Plumbing Pipes: 2 inches of plumbing lines and fittings made of PVC (SCH40).

- Shut-off Valves: Ball valves to provide use of zoned control (Optional on smaller tables).

- Sealants: To make the edges of the MDF airtight, use polyurethane or epoxy.

- Fasteners: Bolts and screws to hold the layer in places to the CNC frame.

- Equipment: CNC router, drill, Forstner bits and glue.

In the case of sourcing materials overseas such as MDF or PVC, one should remember that logistic providers such as GWT Worldwide can be used as they provide cargo delivery with freight forwarding and customs to be cleared, which can be crucial when sourcing small holes for your projects. in order to simplify the shipping process, especially when sourcing smaller parts .

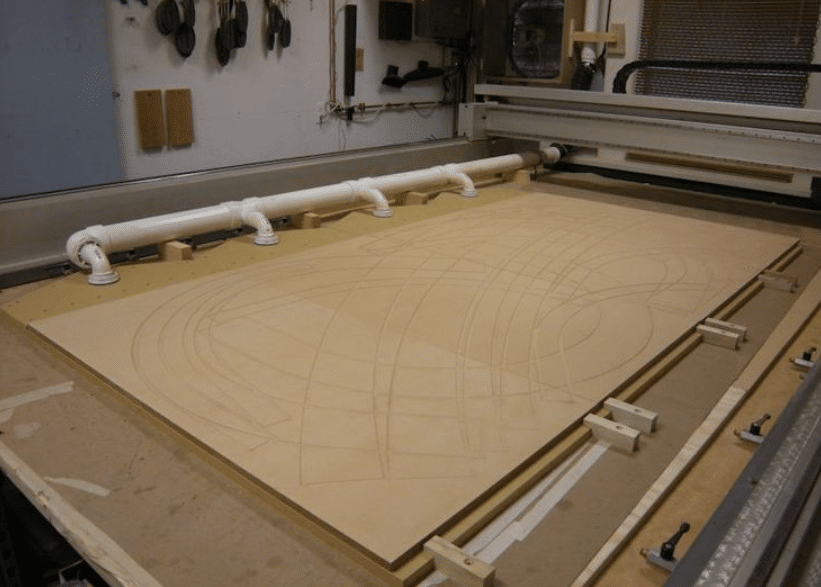

Designing the Vacuum Table Layout

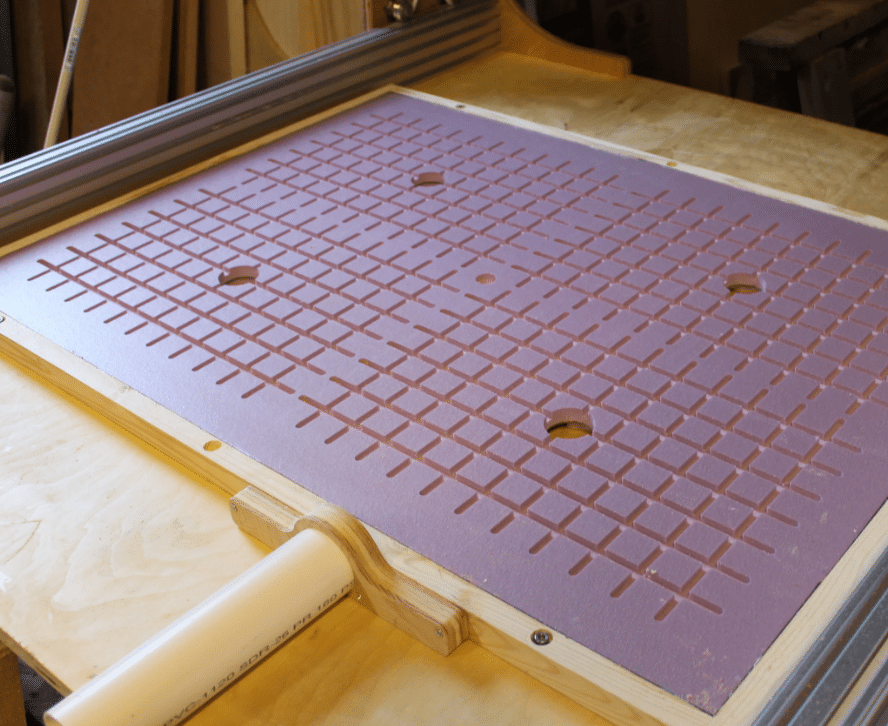

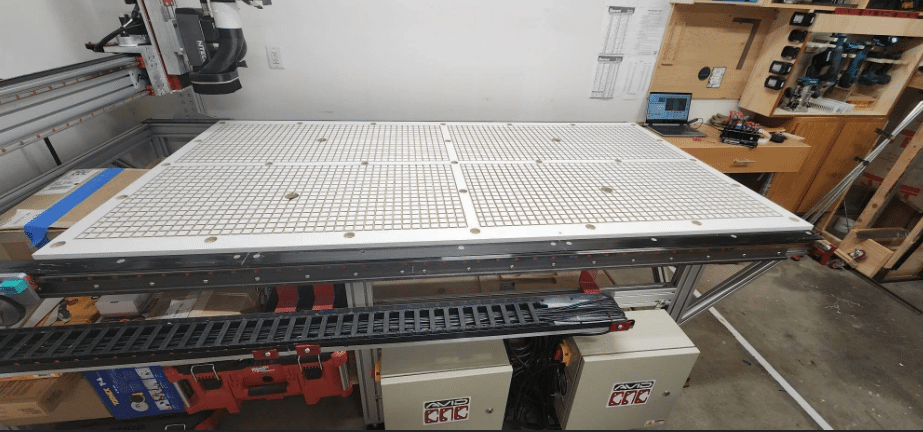

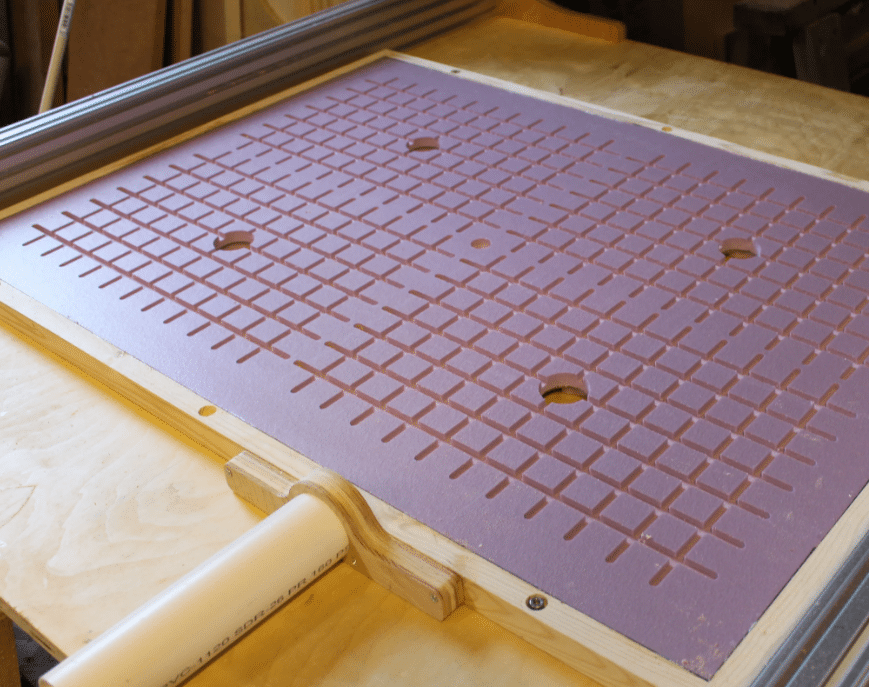

The first part of the design process is to know your table size and zoning. A 4×8-foot CNC will have four 2×4-foot cut areas with central vacuum port and shut-off in the OpenBuilds guide to selective suction. A plenum grid of 2 inch square samples with diagonal gaps to distribute air evenly and enough to fill a plane may be cut, using your CNC, in your plenum, which can be split into different zones . SI make sure the base board is flat, and level so that warping will not cause decreased suction efficiency. In smaller CNCs, a single zone table, like the one in of the Instructables guide might be enough. Design, either by sketching in CAD software or on graph paper to take into account the dimensions of your frames, and your materials.

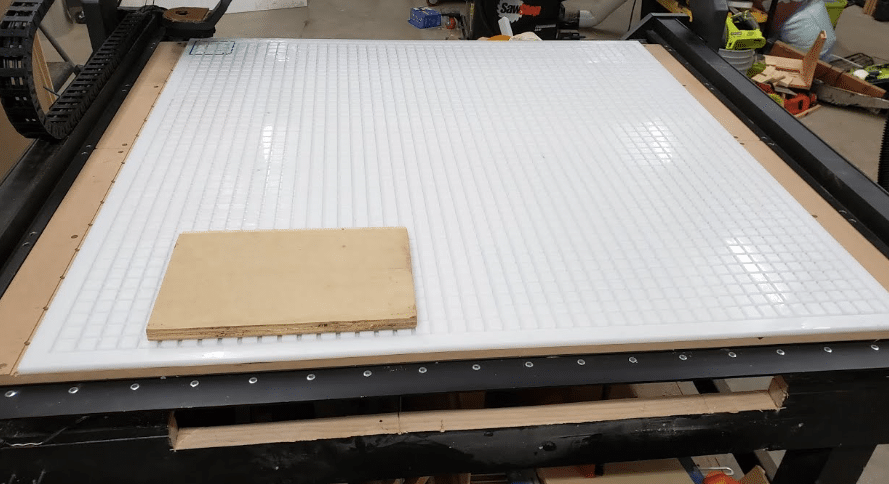

Constructing the Base and Plenum Layers

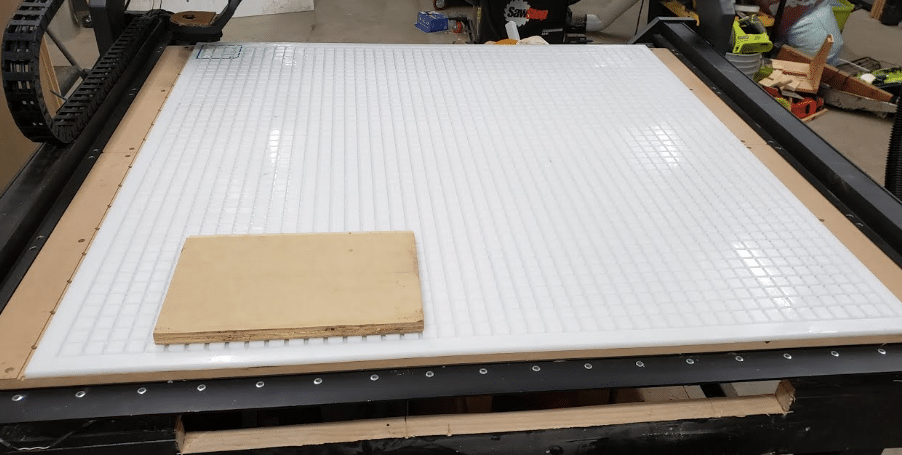

The best start is to get the base board ready, which is usually 18mm Baltic birch plywood or MDF and the surface has to be flat and aligned to your CNC vulgar gait. The Board should be coated as flat as possible, and your CNC is recommended to surface the board, ensuring that the top surface is perfectly flat, in the OpenBuilds guide. Then construct the plenum board; cut grid-like 2-inch squares (and diagonal channels) in MDF or higher density plastic.

The center of each zone drill a through-hole through which the vacuum ports are made. Spray the two boards using polyurethane or epoxy and use additional coats at the cut edges where there might be air leakage. Screw the bottom board to your custom CNC frame to securely attach it. so that it tightly fits to give an airtight holdup. Put the plenum board on top with the vacuum ports to be aligned with the piping that is going to be implemented.

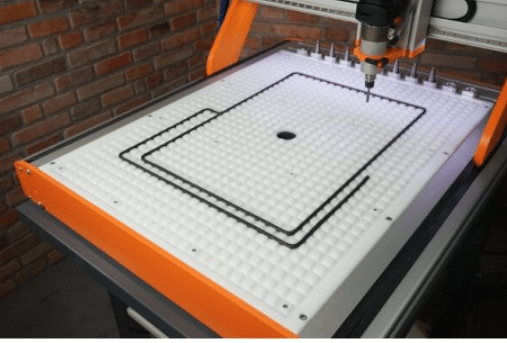

Plumbing the Vacuum System

The vacuum system should possess a quality plumbing that suction is powerful. To connect vacuum port of each zone to the vacuum source use 2 inch SCH40 PVC pipes, as recommended in OpenBuilds. In a zoned table a shut-off valve should be installed on each spot to allow suction to particular areas and cut down on smaller workpieces. All pipes and fittings should be dry-fit together to ensure fitment and alignment, and 90-degree union of fittings with grooves for PVC glue in an airtight seal. The piping network should be connected to a 6hp canister vacuum or shop vac whereby the filter along with the bag have to be removed to allow maximum airflow, which helps in creating sufficient force for suction . To check the system, run the vacuum and check weak places.

Creating the Spoilboard

MOST commonly the porous MDF such as Trupan Ultralite is used as the spoilboard and will permit airflow whilst gripping the workpiece. The spoilboard should be cut into the size of your table and you should cut the reverse side of the spoilboard, as well as the other side, 0.01 inches using the 1-1/2-inch cutting router in order to increase air flow as per the OpenBuilds guide. Ensure that the edges are sealed with polyurethane in order to reduce leakages. Tack the spoilboard to the plenum board so it is quite flat and then tack it well. Instructables guide highlights that the spoilboard might require periodic surfacing under the influence of CNC activities helps clear off any accumulated dust. ; hence preparing replacements as time goes.

Testing and Troubleshooting Your Vacuum Table

When assembled testing the vacuum table by placing a piece of work on the spoilboard and then turn on the vacuum will assist in testing the vacuum table. Assure secure hold-down by trying to raise the material slightly. When the suction is weak then look at plumbing or plenum or spoilboard air leaks. Make sure that the vacuum source can deliver enough suction; a shop vac might be good enough, but a dedicated pump can enhance efficiency. with small tables, but bigger setups might need industrial vacuum motors as Reddit states. You should verify the capacity of your vacuum system Modify shut-off valves to be able to maximize suction in certain areas. In case the workpiece continues to move, you can place some rubber gasket or tape around the edges of the material to obtain a better seal as it is recommended in CNCzone forums.

Tips for Optimizing Performance and Maintenance

To get the best out of your vacuum table, ensure you do the following, incorporating some of the best first thing to do is incorporating some of the best ideas for maintaining your vacuum table. :

- Frequent Repair: Keep the spoilboard clean and change it when it has been worn down which will keep suction.

- Zone Control: By way of shut-off valves, it becomes possible to concentrate suction precisely on areas of activity, thereby saving it.

- Material Selection: the spoilboard should be made of porous MDF in order to balance out airflow and durability.

- Vacuum Source: Using a more powerful suction, the nature of the vacuum source is something to be considered when working with larger tables, on discussions in CNCzone people recommend a 10hp rotary vane pump (among others).

- Sealing: The edges of MDF should be coated with sealant with several applications to ensure they are leak proof.

- Workpiece Prep: Make the workpieces flat and clean as much as possible to maximize suction contact.

Periodically check the vacuum system to determine if they ensure they are not clogged or have leaks., and during assembly, have extra PVC fitting and sealant in case of fast repairs.

Logistics for Sourcing Materials

Import suppliers may be used in getting materials such as MDF, PVC, or vacuum Motors. Multinational corporations such as the Shenzhen Guanwutong International Freight Forwarding Co Ltd (GWT Worldwide) deal specifically in global logistics solutions giving services in air freight, sea freight, China-Europe railway and custom clearance and warehousing. They provide efficient and cost effective delivery of the materials, for example, during bulk orders. which is very important when carrying out your DIY project that could need bulk or specialized items, especially when designing the vacuum chamber . With an established logistics partner, you would be able to concentrate on construction without worrying much about the quality of materials delivered in time.

結論

A DIY CNC vacuum table is only a game changer because they allow those in the hobby or small shop to have professional level work holding system, ensuring the axis is correctly aligned. at a price a fraction of professionally built systems. With a little effort and the help of these steps which are given in this guide with the inspiration of Open Builds and Instructible, you will be able to make a table that will suit the requirements of your CNC, which is a crucial tool for your project . Routine check-up and optimization guarantee sustainability in the long run, whereas the logistic partners, such as GWT Worldwide, make the sourcing of material a piece of cake. Begin your build today to make your CNC work easier and get cleaner and more perfect cuts by maximizing the surface area of your workpiece .