What is Plastic Injection Molding?

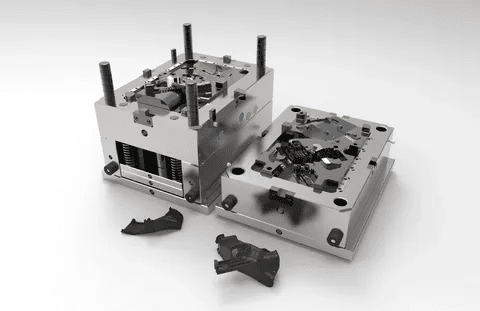

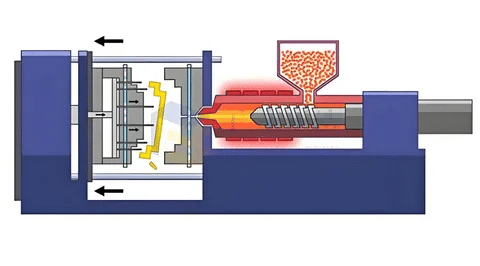

Plastic injection molding is another means of manufacture where an injection of molten plastic material is injected in a carefully designed mat to form a part. It starts with the plastic pellets heated to the melting point, forced into a mold cavity under high pressure and after cooling down, it solidifies to the desired shape. This flexible manufacturing technology has the flexibility to produce very precise and repeatable complex geometries.

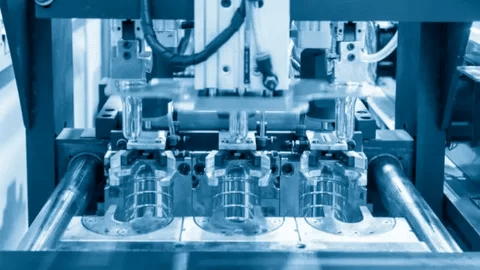

Injection molding is carried out in 4 phases namely clamping, injection, cooling, and ejection. In clamping, the halves of the mold are firmly shut. During the injection stage, molten plastic is forced through the mould cavity. The cooling phase permits the plastic to harden and at last the final product is released out of the mold. The repetition of the cycle is possible thousands of times with the same results.

Advantages of Plastic Injection Molding

The applications of plastic injection molding constitute a lot of benefits that justify its use as the means of manufacturing being used when the volume of the production is large. The technology provides outstanding precision, to the extent of ±0.001 mm tolerance, allowing the stability to be sustainable even in high volumes of production. Complicated geometries can be generated in one operation and hence no more secondary machining or assembly procedure.

Another major benefit is its cost-effectiveness especially when it comes to high volume production. Starting the tooling is expensive but the unit cost falls off ruthlessly with volume. They also mean the fast production cycle, mostly the cycle times are a matter of seconds to minutes, depending on the complexity of parts.

Versatility in materials enables manufacturers to select among hundreds of plastic resins containing particular properties of chemical resistance, temperature tolerance, or electrical conductivity. It is also able to incorporate inserts, overmolding and multi material combinations in the same molding process.

Plastic Injection Molding Applications

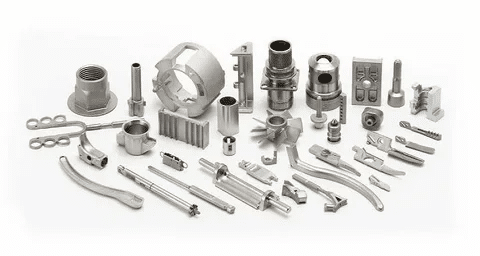

The uses of injection molding include automobile parts and medical equipment as well as other industry applications. The automotive industry where injection molded parts find application are dashboards parts, interior trims, connectors and under-hood that must be especially resistant to high temperatures and dimensional stability.

Smartphone housing, connectors, and precision parts in computers and consumer electronic technology are largely injection-molded in the electronics business. Examples used in the field of medicine are surgery tools, health testing equipment casings, and drug wrappings that are put under stringent regulations.

Toy, appliances, and household products are other consumer products that enjoy the attributes of making consumer products that are attractive, durable with consistent quality that injection molding achieves. Examples of industrial applications are components of automation, machinery housings and precision components of manufacturing equipment.

Plastic Injection Molding Capabilities

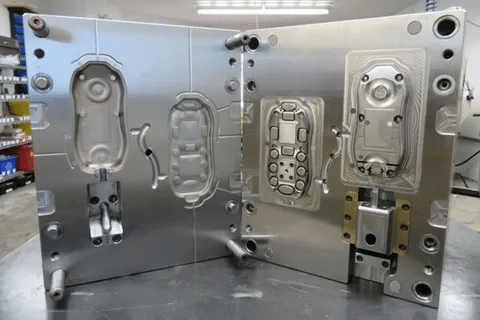

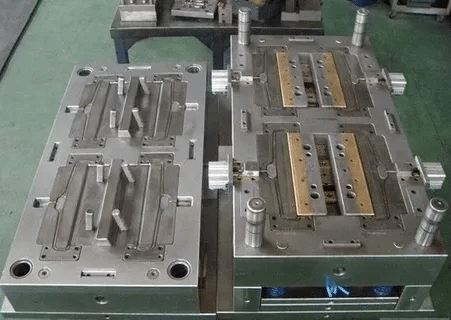

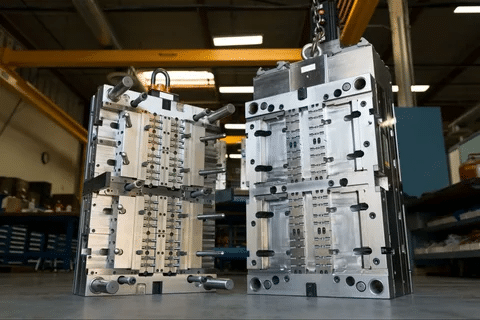

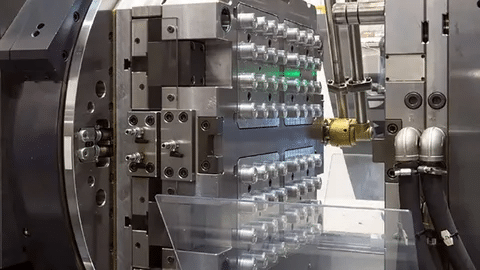

The injection molding capabilities of today are definitely more than simple part manufacturing. High-tech multi-cavity molds can be built to create dozens of parts in each shot, thus making the most of their efficiency and cutting their per-unit production cost. Hot runners systems also save waste and shorten the cycle times by keeping essentially molten plastic at ideal temperatures all through the mold.

The high precision molding can produce micro-components measured in microns and the large molding can produce components of several kilogram weight. Insert molding integrates both metal or electronic pieces and plastic in a single process to yield composite assemblies, which have greater functionalities.

The overmolding processes enables multiple materials to be combined so the products can have various properties with soft-grip handles being one example. Gas-assisted injection molding massively lowers material consumption and cycle time, generating hollow components that have uniform wall thickness, and structural integrity.

射出成形材料

Good injection molding depends on the right materials being chosen. The largest percentage of injection molding applications includes thermoplastic products that can repeatedly be melted and reshaped. Polyethylene (PE), polypropylene (PP), polystyrene (PS) and ABS are the common ones with each having its own properties to suit a particular application.

The designed plastics, like the nylon, polycarbonate, and POM engineering plastics, offer high mechanical performance, resistance to chemicals, and extreme temperatures. High-performance polymers such as PEEK and PPS provide outstanding aerospace and medical performance at the cost of special processing requirements.

Selection of material takes into account such factors as mechanical, environmental resistance, regulatory compliance and cost. The stronger, stiffer Glass- and carbon- filled versions are available and flame-retardant grades are available to meet fire safety demands. Recycles and bio-based products support the sustainability issue and performance.

Design Guidelines

In order to achieve successful injection molding, certain design considerations have to be made to make sure that manufacturability and quality of the part are given. The similarity in walls thickness averts imperfections like warping, sinks, and internal tensions. The thickness of walls varies, depending on what material you use, but in most cases it is between 0.5 mm and 6 mm.

Draft angles, provided of 0.5 to 2, allow evacuation of the parts and safeguards them as well as the mold against destruction. The appropriate design of the radius avoids sharp corners which form stress concentrators and possible failure origins. Its radius is preferable to be 25-60 percent of the wall thickness.

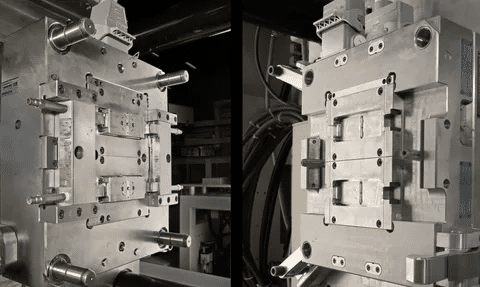

The undercuts and complicate details must face serious consideration to allow appropriate mold operation. Complex geometries are possible with side actions, lifters and collapsible cores but increase the complexity and cost of the tooling. The position and design of gates play a critical role in the quality of parts and the careful placement of gates will reduce the appearance of gate marks as well as eliminate improper filling.

Plastic Injection Molding Services

A full service injection molding goes through the whole way of the manufacturing process, initial consultation and meeting of design up to the final delivery of parts. Design for Manufacturing (DFM) analysis takes a close look at the part and verifies that parts are best suited to injection molding and that these parts can be altered to improve on cost effectiveness during production by stating possible problems among them.

Three-dimensional prototyping services enable both design validation and test of the design prior to accepting production tooling. 3D printing, soft tooling and different rapid prototyping methods allow faster iterations and design improvements. Material testing and validation is done to check the required performance requirements of the materials that have been selected.

Quality assurance systems deploy all inspection procedures, statistical process control and the ever-improving initiatives. The advanced quality systems have part control and part traceability that are consistent across the production. Affiliation assembly, packaging and decoration can be put together as secondary operations.

Why Choose Zecheng Precision for Injection Molding?

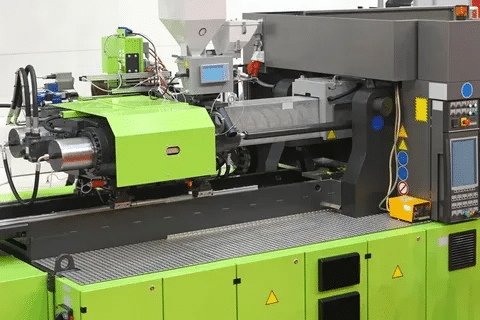

Zecheng Precision has more than twenty years experience in the precision mold industry catering to customers in automotive, medical, electronics, and industrial industries. We have state of the art Japanese production equipment and support technology processing to the standards of parts that are of the highest international standards and those that will meet the demands of GB, JIS, DIN, and AISI among others.

The manufacturing abilities of our precision give unbelievable tolerances of dimension to +/- 0.001 mm, coaxiality to +/- 0.002 mm, and Ra 0.025 finish. These are the mechanical capabilities that serve the most exhaustive applications such as the automotive connector molds, micro- motors components and precision molds of threads.

Since we have a worldwide client formation of Germany, United States, Japan, Italy, Singapore, Thailand and Malaysia we are conversant with market needs and regulations. Our services in full DFM support, custom productions, and coverage of quality also guarantee quality production that goes beyond the expectations of clients, and precision is reliable.

Injection Molding Resources

Successful practices of injection molding should be followed by continuous learning and keeping up with industry tendencies. Technical documentation incorporated is the material property databases, design guidelines, and processing parameters that assist in superior part design and manufacturing. Industry associations supply norms, best operations and networks.

Training programs include principles of the basics of molding to complicated troubleshooting problems. Certification programs confirm knowledge and confirm standards in the industry. In technical publications and conferences, the reader gets the insight into the newer technologies and market trends.

Development for the mould flow analysis, structural analysis and cost estimation are provided through software tools hence the mould flow analysis, structural analysis and the cost estimation can be done with the right decision being arrived at. Tooling is anticipated to have problems by using simulation software and it will take less time and money to develop better tools that will make parts.

結論

Injection molding is one of the widest and effective manufacturing processes of today. Precision, speed and cost-effectiveness of use are what make it the popular system when it comes to production of high volumes in varied industries. High chance of success in injection molding depends on paying attention to design, the choice of materials and optimization of the process.

With the current advancement in technology, injection molding is also developing to fit the changing needs in the market. The future of injection molding is occurring through digital manufacturing, industry 4.0 integration and sustainable materials. The firms which invest in high level parameters and remain quality conscious and precise will still survive in this dynamic field.

The secret of successful injection molding is to work with the manufacturers who know the technical requirements as well as business goals. Through proper planning, design improvements and management of quality, injection molding produces superior results of utmost specifications at cost-effective prices.