Meta Description: Learn which saws are the most recommended in cutting aluminum, tricks and tips on cutting, and safety precautions. Find out how to produce clean cuts and improve your projects using the appropriate tools.

Introduction

Trimming of aluminum can be a heavy task and most especially without the necessary tools. As a professional or the DIY enthusiast, it is important to grasp knowledge of the best saws to use to cut steel and aluminum as a way of trying to get clean and precise cuts. This guide will identify the different classes of saws, methods and safety precaution tips so that you can have the best outcome.

Understanding Aluminum as a Material

Aluminum Aluminum is a non-ferrous easily castable metal that is always found in the industry, be it the automotive or aerospace industries. Due to its qualities, it fits perfectly in a variety of applications, but it needs special tools and methods to cut it. Because aluminum is subject to burrs, and can easily warp when not cut properly, it is an imperative to select the appropriate saw.

Types of Saws for Cutting Aluminum

1. Circular Saws

One of the most used tools of cutting aluminum is the miter saw, along with circular saws. They are flexible and able to process different thickness of aluminum sheets. Operating circular saw, it is necessary to install a special blade, intended to cut non-ferrous metals. These blades are usually shorter with less teeth and fabricated in carbide to minimize their friction and heat.

2. Miter Saws

Miter saws would be best suited when quite accurate cross cuts and angled cuts in aluminum are required. They provide a solid base and a stationary cutting angle and are thus ideal in work involving precision. Miter saws similar to the circular ones should also have saw blades cut in aluminum so that clean cuts are made.

3. Band Saws

Aluminum pieces that are thicker will cut excellently with a metal cutting blade on band saws. They give machine continuous cutting action that cuts down the possibilities of chips and warping. Aluminum band saw blade tooth pattern is slightly different so that friction is reduced to the minimum and heats do not accumulate thus cutting is smoother.

4. Jigsaws

Intricate shapes and cuts in the form of curves in aluminum can be cut using jigsaws. They are simple to work with and can be applied to straight and curve cuts in cutting aluminum extrusion . When you are using a jigsaw, it is essential that you use a special blade that is used in cutting metal to have the best outcome.

5. Cold Saws

Cold saws: the cold saw is a specialized tool used in cutting aluminum at low speeds. It produces fewer heat and will therefore warp less and will also provide a clean cut. Cold saws are ideal when it comes to high-volume production and can cut thicker materials without any problem.

Choosing the Right Blade

The thing is that it is no less important to choose the appropriate blade than the appropriate saw. When cutting aluminum, you should find safety glasses a a blades which have the following qualities:

- Material: The use of the carbide-tipped blades is the best choice when it comes to cutting aluminum because of its long-lasting and durability component.

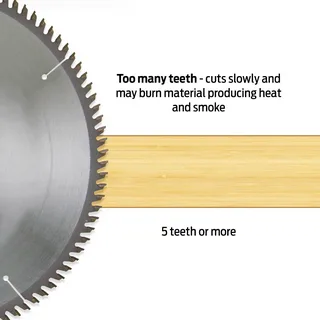

- Tooth Count: A lesser amount of teeth in the blades (60-80) is appropriate when working with aluminum, and minimizes friction and generates less heat.

- Tooth Design: Seek blades that have a positive rake angle as these would assist in cutting through aluminum with better efficiencies.

Techniques for Cutting Aluminum

1. Secure the Material

Make sure the workpiece, which is the piece of aluminum, is clamped directly to a sturdy surface before performing any cuts. This eliminates movement when cutting, which would otherwise result in incorrect cut and even injuries.

2. Use Proper Speed Settings

In working with power saws, the speed settings should also be adjusted based on thick aluminum. The thicker materials tend to do well at slower speeds though thinner sheets can be run at high speed.

3. Lubrication

Friction and heat created by the process of cutting may be minimized by applying a lubricant, like cutting oil. Not only will this extend the life of the blade but will also lead to less dirty cuts.

4. Take Your Time

Hurrying during cutting may result in errors in making the cut, and wearing a full face shield is advisable to prevent injuries and ensure safety. Do not be in a rush and make sure that you are careful to control the process, it is the saw which performs the job.

Safety Measures When Cutting Aluminum

When using power tools, safety must be a consideration. The following are some of the safety precautions that should be followed:

- Wear Protective Gear: Safety goggles, gloves and ear protection must always be used when cutting aluminum.

- Check Your Tools: Before beginning work file, inspect your saw and blade as to whether it has any damage or expidition.

- Keep Your Workspace Clean: work area usually gets cluttered causing accidents. Make sure that your space is clean and tidy.

- Follow Manufacturer Instructions: you can never go wrong; every saw and blade has a specific following.

結論

It is not always a complicated task to cut aluminum and you will only need proper tools and methods. With a little knowledge of what kind of saws for aluminium are in the market and also being effective in the use of those saws, you can accomplish clean and precise cuts and make repairs when working on your projects cutting process Always work safely and slow down, so that you can achieve the best outcome radial arm.