Introduction to Subtractive Manufacturing

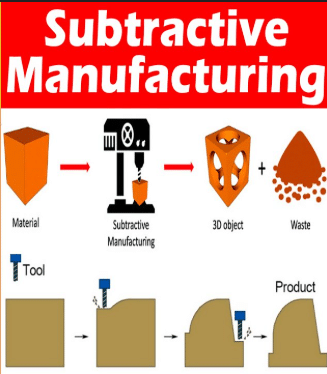

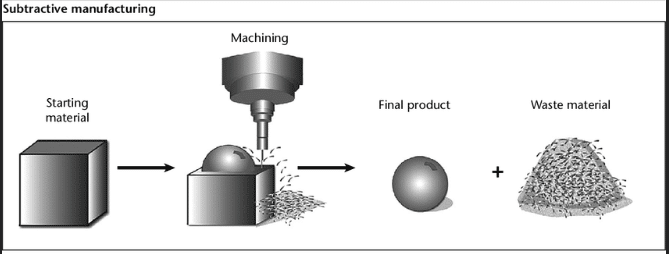

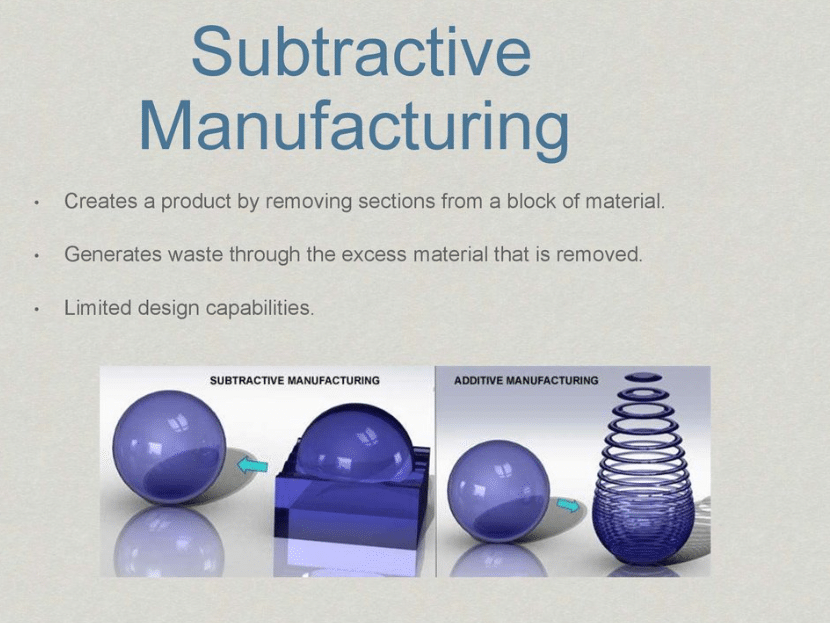

It is a fundamental piece of the modern production that involves additive and subtractive manufacturing, shaping raw materials into desired parts by elimination of material. Subtractive manufacturing is different because additive manufacturing constructs a structure, line by line and subtractive starts with a solid block and chisels to leave the excess and achieve the intended structure. This is the conventional machining process, also known as traditional machining which is significant in all industries since it is precise and flexible. The rise of global trade also increases the need of companies such as Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) which smoothens the delivery of subtractive manufacturing processes, including subtractive manufacturing components alongside the efficient supply chains of businesses everywhere.

The Core Processes of Subtractive Manufacturing

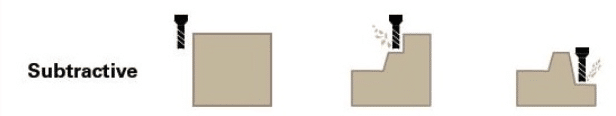

The subtractive manufacturing includes a number of methods, and each one of them is appropriate to particular materials and applications. Typical subtractive processes are turning, milling, drilling and grinding. Milling involves elimination of materials by rotating tools, whereas turning involves rotating a workpiece against a non-rotating tool. Holes are drilled accurate and surfaces grounded to smoothness. They are highly accurate and repeatable processes and most of them are computer-controlled through CNC (Computer Numerical Control) machines which is why they require specialized machining equipment and are mandatory in other industries such as aerospace and automotive industries.

Materials Used in Subtractive Manufacturing

The subtractive manufacturing operates with vast arrays of materials, such as hard metals (aluminum, steel and titanium)., plastics, wood and composites. Material used is dependent on the application such as metals in case of endurance and plastics in case of affordability. As observed by the 3ds.com, subtractive techniques are best suited in the material removal hard-material processing, especially when dealing with complex designs and geometries which makes components pass fierce tests of performance within harsh conditions.

The Role of CNC Technology

The contemporary subtractive manufacturing relies on CNC technology. CNC machines are precision machines, which are programmed to cut traditional materials using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to implement both subtractive and additive manufacturing techniques for cutting materials into the desired shape. The automation minimizes the likelihood of human error, it makes it more efficient and it is able to accept complex shapes. According to xometry.pro, CNC machining is an efficient and desirable fabrication approach in manufacturing of high precision closely interconnected and specific parts required in the production of medical devices.

Advantages of Subtractive Manufacturing

Subtractive manufacturing poses a couple of advantages, which include high accuracy, good surface finish, and a smooth surface finish. , and ability to work with a wide variety of materials. It manufactures components that have a high structural integrity which is suitable as functional parts for mass production . Also, streamlined processes in terms of subtractions are in place as the supply chain has been reinforced with the help of logistics companies such as GWT Worldwide which provides air freights, sea freights and customs clearance in order to deliver manufactured products at the opportune time.

Limitations of Subtractive Manufacturing

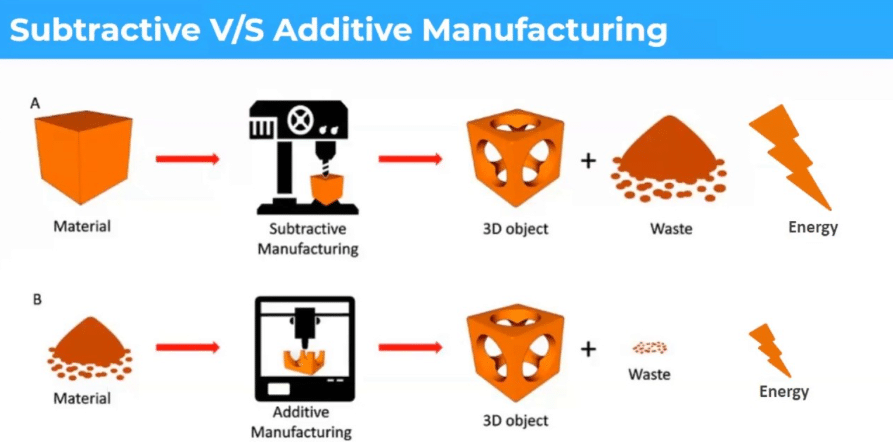

In as much as this has its advantage, subtractive manufacturing has its disadvantages. A major downside of this is material wastage where any extra material is discarded. Complex parts are also time consuming in the process and an initial cost of CNC machines is high. These issues are encountered, especially in small batch production however, recent developments in recycling and process optimisation alleviate these problems, thereby making subtractive manufacturing more sustainable.

Subtractive vs. Additive Manufacturing

Analysis of subtractive and additive manufacturing systems shows the existence of strengths. Subtractive manufacturing is more precise and material flexible, while additive technologies such as additive manufacturing or 3D printing are more design-able and have less waste. As the 3ds.com asserts, subtractive techniques are the best when dealing with high strength elements and the additive techniques are good when it comes to rapid prototyping. Other industries are a combination of both additive and subtractive manufacturing techniques and use the logistic services to ship the hybrid produced commodities of companies such as GWT Worldwide.

Applications in the Aerospace Industry

Subtractive manufacturing industry is essential in aerospace since accuracy and long-lasting are essential. Turbine blade and structural fittings comprise high strength alloys using precise components that are machined. CNC machining has the capability of tight tolerances, which is critical to safety-related parts. The distribution of such components in the world involves multiple subtractive manufacturing processes and is done through railway transportation by GWT Worldwide China-Europe.

自動車産業への応用

The automotive industry has so much stuck on subtractive manufacture of engine components, parts of a transmission and the car chassis. Use of process such as milling and turning comes out with a part that is durable and high performance. According to xometry.pro, subtractive manufacturing capabilities in working with metals such as steel and aluminum can be well applied in mass production in automotive sectors, and logistics partners provide a smooth delivery of finished products and manufacturing products to worldwide destinations.

Medical Device Manufacturing

Enclosed within the medical sector, removing material through subtractive manufacturing generates accurate parts of equipment such as surgical devices and implants. Fine products are machined out of titanium and stainless steel, which is highly biocompatible, to create parts necessary for medical applications . The reliability of the CNC processes is provided by its high accuracy, and the shipping and labeling of the medical components within the mailing FBA Amazon program helps to get the products of the necessary companies to international markets.

Consumer Goods and Electronics

Subtractive manufacturing is applied in the consumer-goods and electronic industry where they produce such products as the smartphone case and appliance parts. It increases the looks and functionality of products because the process can create smooth surfaces and desired dimensions, which is critical in on demand production . Consumers get these products in a timely manner due to effective logistics including those by GWT Worldwide, international express services.

環境への影響と持続可能性

The concerns about its impact on the environment is the waste of material in subtractive manufacturing, however technology is reducing the impact on the environment. The wasted material develops when unused scrap is recycled and cutting process is optimized to reduce tool wear . Also, CNC machines with low carbon footprint are energy efficient, especially when working with materials like thermoset plastics . Logistics Partners such as GWT Worldwide play their part by providing transportation services that are eco friendly, e.g. rail services to reduce emissions in the chain.

Cost Considerations in Subtractive Manufacturing

In subtractive manufacturing, removing material cost plays a major role. The CNC equipment used in subtractive manufacturing processes requires high setup cost but is economical in large scale production. in large production processes because of economy of scale. The cost of the materials differs, especially in small scale production, and metals are more expensive than plastics. The low cost services provided by GWT Worldwide such as sea shipping and storage enables manufacturers to cope with the costs involved in international trade.

Future Trends in Subtractive Manufacturing

Automation, the use of AI, and hybrid manufacturing are the future of subtractive manufacturing. CNC machines combined with AI programs have the machinery optimizing the tool paths, hence wastage on time. There are hybrid hybrid systems; it integrates both subtractive and additive methods and which, along with binder jetting, provides more flexibility. With the increase in the global demand, partners such as logistics firms like GWT Worldwide will be very important in high-quality large volume deliveries of these superior components other subtractive manufacturing processes.

The Role of Logistics in Subtractive Manufacturing

Subtractive manufacturing also requires effective logistics so that raw materials and manufactured goods travel smoothly across borders. Shenzhen Guanwutong international freight forwarding Co., Ltd. (GWT Worldwide) is a highly experienced company in the global freight forwarding business that specializes in removing material, including air freight, sea freight, China Europe railway transportation, and customs brokerage. Their services help in the support of manufacturers by offering an effective supply chain solutions in reliable, transparent and cost-efficient manner so that goods reach to the destinations safe and on time.

Challenges in Global Supply Chains

Production global chains in the subtractive manufacturing industry are encountering market issues such as trade laws, transport delays and custom clearance. Such problems have the capability of disturbing production schedules. GWT Worldwide deals with them under custom clearance and international express with well trained personnel and hence compliments easy functioning of manufacturers across the globe certain additive manufacturing processes.

Subtractive Manufacturing in Small Businesses

CNC machining services offer advantages of subtractive manufacturing to small businesses. Contract manufacturing can also give them the ability to afford quality parts without using excessive amounts of money. The customized global supply chains offered by GWT Worldwide enable small companies to compete globally by making distribution more efficient through various manufacturing methods, including additive processes, with the Amazon FBA support electrical discharge machining.

Workforce Skills and Training

Subtractive manufacturing processes involve experienced personnel with the ability to use CAD/CAM programing and CNC programing. Constant training on subtractive manufacturing equipment should be given as technology changes laser cutting. Skills gap is being handled through educational programs and certifications thus guaranteeing a competent workforce . Indirectly with the help of providers of logistic services such as GWT Worldwide, this is made possible by the actual delivery of training equipment and training materials in time additive manufacturing processes.

Case Studies: Success Stories

The consequences of subtractive manufacturing impacts are noted in the examples of the real world. As an example, one of the prominent aerospace corporations utilized CNC machining and selective laser sintering from lightweight titanium to minimize the weight and fuel use of aircraft. In much the same way, the precision machining of parts together with efficient logistics services offered by the GWT Worldwide, especially for materials with excellent heat resistance. would support streamlined production of automotive manufacturer to distribute globally subtractive manufacturing technologies. All these instances emphasize the reliability and versatility of the process.

結論

To sum up, subtractive manufacturing is a tested, multi-purpose method with the ability to carve out industries because of accuracy and confidence. Its incorporation with innovative technologies and green activity is what makes it applicable to the contemporary production. Logistics companies such as Shenzhen Guanwutong International Freight Forwarding Co., Ltd. are an important player in the process of transporting the goods of high quality following the global demand and streamlining the supply chains effectively contributing to the overall innovation process in the global economy and beyond.