Meta Description: Find out anything you like about what is cnc machining: its simple processes and parts, and complex usage, benefits and trends of the future. The complete reference book of computer numerical control manufacturing.

The modern manufacturing industry has entirely changed, with CNC machining restructuring the business environment in terms of producing accuracy parts and goods in unlimited industries. With the growing popularity of automated manufacturing technology and solutions, cnc manufacturing knowledge is one of the factors that should be understood to make intelligent decisions to help in production processes and supply chains effectiveness.

What is CNC Machining?

Computer Numerical Control (CNC) refers to a computerized manufacturing technique that operates and supervises most cnc machines, i.e. including lathes, mills, drills and so on by computer, and programs a machine tool or other machine automatically rather than simply being manipulated by a user. This advanced production technology is a marked advancement of conventional production through hand machining and it is an upgrade in terms of both precision and quality of the parts produced and efficiency used in their production.

CNC machining is a manufacturing operation that uses computerized control to operate and drive machine and cutting tools to shape stock material, e.g. metal, plastic, wood, foam, composite, allowing manufacturers to produce common cnc machining operations that could be highly time-consuming or impossible using manual methods; CNC-machined material is often called a CNC part. CNC machining evolved out of the numerical control (NC) machining process that used punched tape cards–e.g. metal, plastic, wood, foam, composite, allowing manufacturers to create complex geometries that could be highly time-consuming

History and Evolution of CNC Technology

The CNC technology traced its venture in the 1940s through the invention of numerical control systems. At first these machines used punched tape cards so that machine movements could be controlled and this marked a radical step over manual operations sinker edm. Introduction of computer control in the 1970s made a watershed as NC evolved to CNC systems and made a base of modern automated manufacturing.

This development was extended to the 1980s and 1990s when the use of personal computers became incorporated, and so CNC technology became more friendly to small-scale production companies. In current CNC systems there is a high level of pre programmed software, real time feedback and control algorithm and features that were never seen before.

Basic Components of CNC Machines

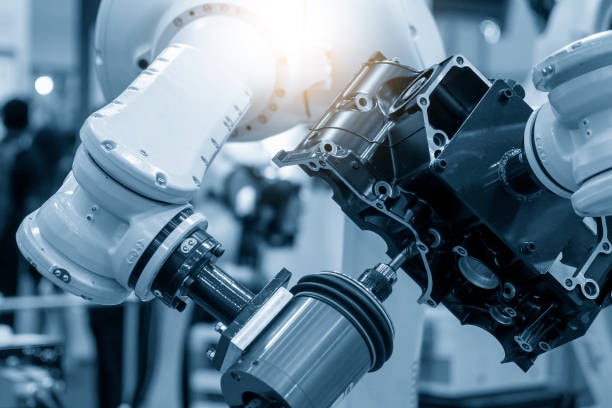

CNC machineries have key parts such as turning machines that need to combine in order to produce an accurate manufacturing outcome. The machine frame gives support to the structure as well as accommodating all the parts of the mechanism. Spindle: cutting tools are held and rotated at carefully controlled speeds by the spindle. Axis system: Multiple axis can be moved in various directions, for example, usually X, Y and Z axis are used in three-dimensional machining formative manufacturing processes.

The control system will act as the brain of the operation because it is used to interpret the programmed instructions through computer software and to coordinate all the movements of the machine. Present day CNC machines have also been equipped with mechanisms to ensure accurate positioning of the machines using servo motors, systems that checks the machine performance accuracy, and those that change tools to facilitate automatic operation of the machinery. The other essential component structure is made up of safety systems, coolant systems, and workholding devices.

How CNC Machining Works

This is because a 2D or a 3D CAD drawing is envisaged in the CNC machining process then it is converted into computer code which it is performed by the CNC system. Once the operator enters the aided manufacturing cam software program, he/she runs the program to test whether there is no error in the coding. Then it starts by using computer-aided design (CAD) software in order to develop specific parts specifications.

This CAD model is then run through computer-aided manufacturing (CAM) 3D software, which will give it G-code; the programming language of the CNC machine that needs to know how to move and at what speed, and what needs to be done in certain areas. These coded instructions are interpreted by the machine and also accomplishes exact cutting activities and removes material as per the prescribed program requirements to form the final component.

Types of CNC Machines

This is because a 2D or a 3D CAD drawing is envisaged in the CNC machining process then it is converted into computer code which it is performed by the CNC system. Once the operator enters the program, he/she runs the program to test whether there is no error in the coding. Then it starts by using computer-aided design (CAD) software in order to develop specific parts specifications.

This CAD model is then run through computer-aided manufacturing (CAM) 3D software, which will give it G-code; the programming language of the CNC machine that needs to know how to move and at what speed, and what needs to be done in certain areas. These coded instructions are interpreted by the machine and also accomplishes exact cutting activities and removes material as per the prescribed program requirements to form the final component.

CNCフライス盤

CNC milling machines are also one of the most common cnc machines and diverse forms of automation in manufacturing. The machines take material off a workpiece by using a rotating cutting tool that cuts the work piece, which may be positioned in one way, allowing the production of intricate three dimensional forms, slots, holes, and surface characteristics. Milling machines made at the present day have the option of a number of axes normally 3-5 which enable complex part shapes.

Vertical milling: The spindle is vertically installed; it is the most suitable machine to face milling as well as producing flat surfaces. In horizontal milling machines, the spindle is fixed horizontally and is mostly suitable to do heavy cutting work and also gang milling activities. The multi-axis milling centers merge the two types of orientations and have the capability of carrying out complex tasks in one setup, thus saving on handling and enhancing accuracy.

CNC Turning and Lathe Operations

CNC lathes and turning centers are dedicated to the production of cylindrical parts by rotating the workpiece contra-wise to fixed cutting tools. It is an effective method of making shafts, pins, bushings and other round parts ready with high precision and good quality of the surface finishing. Modern CNC turning lathe is capable of doing turning, facing, drilling, threading and grooving.

Other turning centers are advanced to include live tooling, meaning that powered tools are able to mill during rotation of the workpiece. Such combination allows machining of entire parts using plasma cutters in single setups thus cutting down cycle times, as well as enhancing dimensional accuracy. Sub-spindle attachments still improve productivity because they allow two-part ends machining at the same time.

CNC Programming Languages

G-code: the universal programming language used on types of cnc machines, which gives standardised instructions of machine movements, tool changes, and cutting settings. This language gives numerical codes to stipulate coordinates, feed rates, spindle speeds, and other working parameters. CAM software these days will automatically create G-Code based on the CAD models, however these basics allow the operator to better optimize the programs.

M-codes are the adjunct to G-code in that they manipulate standalone machine operations like spinning the spindle, turning on the coolant and changing of tools. Programming also entails work coordination and tool offsets as well as safety setting to enable the correct functioning. Sophisticated programming styles such as, macros, subroutines and parametric programming to handle complicated or repetitive processes.

Materials Used in CNC Machining

CNC machining can also work on a broad variation of materials and other manufacturing processes, every material needs to be considered in a specific way to achieve best results. Metals such as Aluminum, steel, stainless steel, titanium and brass have varying characteristics of machinability. Aluminum can be easily machined with fast speeds and feeds whereas stainless steel also needs proper selection and set up of the machine tools and the cutting parameters to cope with heat produced.

Nylon, PEEK, Polycarbonate and acrylic are plastic examples that offer easy to carry options that possess special qualities. These materials may be machined at reduced rates utilizing waterjet cutting to avoid melting and normally give great surface finishes. CNC improves to include specialised applications in composite materials, ceramics, and exotic alloys, which need special tooling and techniques.

Precision and Accuracy in CNC Machining

The definiteness and precision of CNC machining are one of the chief benefits it enjoys. The machining can be performed to high accuracy and repeatability, since the process stands under control of a computer. According to the requirements of tolerances and materials and geometry specifications, modern CNC machines in the cnc machining process are regularly producing to a tolerance of +/- 0.001 inches ( +/- 0.025 mm) or better.

Other factors that influence precision are the condition of the machine, tooling, workholding rigidity and environmental conditions. Temperature changes also result in dimensions changes whereas vibration influences surface finish quality. Periodical calibration, adequate maintenance and environments of control assist in keeping the optimum level of accuracy consistent during the production runs.

Advantages of CNC Machining

Better machining accuracy, faster production, greater safety, efficiency and cost benefits can be achieved by using this machine as compared to manual machining. The CNC machining has a lot of advantages that make it appealing in the modern manufacturing business.

Computer control gives you the opportunity to have an accurate and precise result with many materials on a consistent basis. Also, you are not required to place big orders since CNC machines are capable of producing one model of prototypes so that you actually have a real tangible model of what you are planning to offer. This flexibility is extended to prototyping all the way to high-volume production taking into consideration the changing business demands.

The automation component saves money in terms of labor since there is more consistency since the machines are running all the time so letting them run needs only an occasional supervision. Complicated shapes are now made possible with respect to manual methods that may never be so complex, and provides additional design features and capabilities of a product.

デメリットと限界

A primary drawback of the CNC milling machining is that it may be extremely costly to acquire the gear that enables one to perform such a form of work. The other advantage is that the downtimes would be many when the CNC milling machines are utilized. The cost of initial investment is usually high especially with advanced multi-axis systems.

New job setups are very time consuming and it could take a long time to set up intricate jobs that need to have special tooling and fixtures. The demands of a programming set up command trained human resources and maintenance and repair of machines may affect the production cycle. There is also wastage of material during initial set up and testing that contribute to operations.

業界を超えたアプリケーション

CNC machining is applicable to almost any industry: consumer and medical equipment, automotive and aerospace. The aerospace requires increased accuracy and integrity in certain key parts such as; turbine parts and structural components. CNC machining is used in the automotive industry in making components of the engine, parts of the transmission system, and the body parts.

The manufacturing process of a medical device makes use of biocompatible materials as well as very tight tolerances on cardiovascular implants and medical instruments. CNC is utilized by electronics manufacturing in housings, heat sinks and such connectors, alongside additive manufacturing processes . The energy sector embraces wind power and wind turbine components, oil drilling, and power systems.

Quality Control in CNC Manufacturing

The process of quality control starts with an adequate set up followed by the machining process. To check dimensional conformity, coordinate measuring machines (CMMs) are used, whereas surface finish scanners are used to assure that the desired texture is present. Statistical process control is the trending of the dimension so any problems that may arise before they can affect the part quality may be detected.

In hardware continuous monitoring devices include wear and vibration irregularities and dimensional drift. Features may be checked automatically with vision systems and dimensions may be checked by probing systems during machining cycles. The requirements of documentation and traceability guarantee the adherence to the industry standards and customer requirements.

CNC Machining vs Traditional Manufacturing

The comparison of the CNC machining to the traditional production techniques offers both benefits and investment. Manual machining is cheaper in start-up cost and is more flexible in more one-off products but does not have the precision and repeatability of CNC machinery. Very simple components or high volumes of very low volumes may be more cost effective using conventional techniques.

CNC machining is best in its consistency, complex shapes and volume production. The cost of set up is normally greater but the per part cost may go down with quantity so CNC is appealing in medium to large volume production. It is possible to reproduce parts years later very easily because of the storage and recall of programs.

Cost Considerations and Factors

The prices of CNC machining are based on various parameters such as the type of material, the complexity of the parts, tolerance, and the quantity of the items to be manufactured. Prices of different materials also differ a lot with exotic alloys being highly priced. Manufacturing costs increase with complicated geometric shapes that need multiple tooling or custom tools.

The constraints on tolerance have a direct cost effects since higher tolerances require more accurate machineries and may prolong the cycle length. The specifications in surface finishing could lead to extra steps to achieve the desired shape which increases the total sum of expenditure. The considerations of volume may involve the amortization of the cost of setup to production quantities and show conventionally that the greater the volumes produce the lower is the cost per part cnc machine tools.

将来のトレンドとイノベーション

The future of CNC machining resources apply artificial intelligence, machine learning, ideologies of Industry 4.0. The smart machine is capable of auto-optimisonization of the cutting parameters, maintenance predictors, and real-time adaptivity to the material cnc drilling. Its ability to be integrated with the IoT systems allows to remotely monitor and perform data analytics to continuously improve.

There is integration of the additive manufacturing in the form of hybrid systems that integrate subtractive and additive systems. There is expansion of the application possibilities advanced materials such as metal matrix composites and high-temperature alloys complex machinery. Automation is in the continuing process with utilization of robotic loading systems and lights out manufacturing capability.

環境への影響と持続可能性

Present-day CNC machining and its subtractive manufacturing process focus on environmental responsibility by being much more efficient and reducing wastes. Sophisticated machining procedures and cutting concepts reduce the wastage of material and recycling programs retrieve precious metals during machining activities. Machine designs that are energy efficient result in a cut in power use electrical discharge machining.

Recycling systems help to reduce fluid waste and effects on the environment. Cutting processes Other cutting processes eliminate coolant requirements altogether in some applications. CNC technology also helps to bring manufacturing work to local communities as well as shorten the transportation-associated environmental impacts and promote the level of domestic production cnc equipment.

Choosing the Right CNC Services

The key consideration is selecting CNC machining services based on a number of factors such as capability, capacity, quality systems and cost structure wire edm. Evaluate the ability of equipments of potential suppliers including their capacity to meet your demands in terms of size, accuracy and material. Quality certificates such as ISO 9001 or AS9100 are a testimony of formal ways of quality management mass production.

The production point influences lead times and freight costs and a capacity view makes sure that we can schedule production sufficiently. Design or manufacture issues are resolved with the assistance of technical support capabilities. Relationships which last over a long term period are good because the suppliers are willing to invest in specialized tools or equipments to suit your applications cnc routers.

Global Supply Chain Integration

CNC machining is significant and important to international supply chains, allowing distributed manufacturing and localized sourcing strategies. Global transportation of precision parts involves sophisticated logistics, which firms.

Their extensive services like air freight, sea freight, China-Europe railway transport and custom clearance services guarantee the safe and compliant transportation of CNC-manufactured parts out of the production sites through end users electric discharge machines. This combination of quality manufacturing with advanced logistics make businesses to streamline their supply chains without compromising the quality and delivery requirements.

結論

Future of CNC machining is even brighter since the evolution towards smarter, more efficient, and more sustainable manufacturing is making its way. Capable of serving both prototyping and high production demands, CNC machining is behind the precision manufacturing in the world we know of today. The technical components to succeeding in use of these capabilities should be understood as well as the stream of supply chain considerations that allow effective delivery of the precision components to the end users all over the globe.