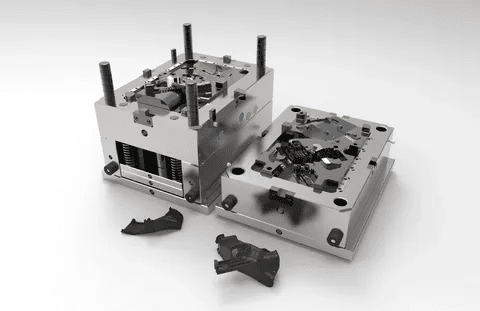

Flow Lines in Injection Molding: Comprehensive Guide to Causes, Prevention, and Solutions

Flow lines Flow lines in injection molding are cosmetic flaws that leave streaks or wave patterns of plastic flow directions. They are caused by changes in temperature or wrong processing parameters or mould design. Prevention involves finding an optimum solution to the selection of materials, injection factors, mold design and cooling systems. Effective control requires systematic troubleshooting, effective training, and thorough mechanism of quality control in order to sustain quality in production.