Understanding Flatness in GD&T: A Precision Manufacturing Guide

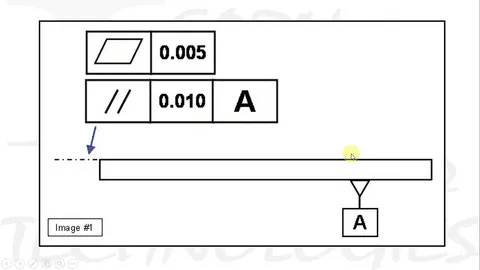

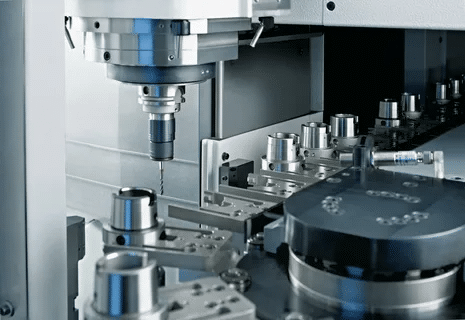

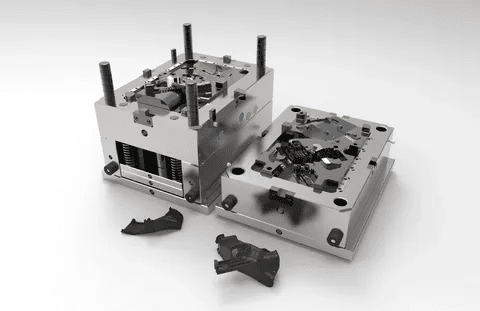

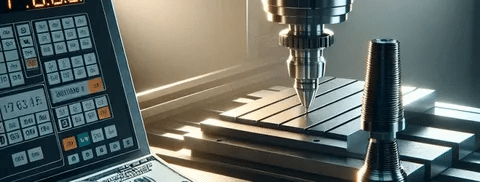

Flatness in Gd t is such an important type of form tolerance which guarantees that the surfaces are contained in a set of specified planes of parallelism which is necessary to assemble the components properly and also use them effectively. Evaluation is based on a measurement of the deviations of the surface with the application of such tools as CMMs, laser systems and optical profilometers, where systematic sampling, plane fitting and analysis of deviations are performed. Correct handling of flatness avoids assembly error, guarantees sealing performance and manufacturing uniformity and is therefore essential in precision work wherever tight tolerance requirements and consistent operation of component are mandatory as in automotive precision work, medical equipment and semiconductor manufacturing.