Meta Description: Find out everything about 3d printing of plastics PLA and ABS as well as advanced materials in the medical sectors . The complex introduction of the methods, usages, troubleshooting and opinion of the 3D plastic printing technology.

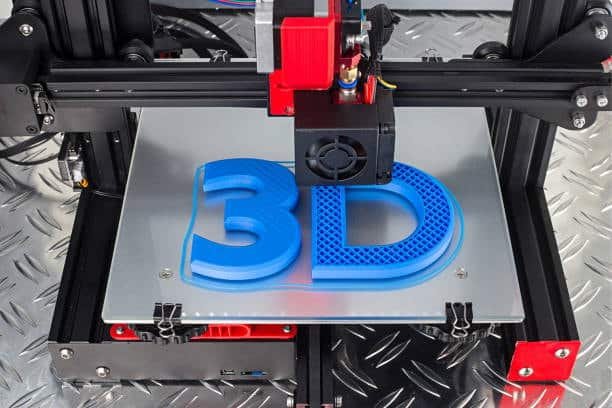

The new applications of the plastic material in the manufacturing, prototyping and the creative industries have been changed in the 3D printing world. As the demand rises and the technology of additive manufacturing evolves over the years, it is important to ensure that both the new-comers and professionals to understand about what are the different types of plastic filaments, also such as engineering resins, and that which they are manufactured in. This is probably a full account of all the possibilities of the 3D printing using plastics, with the basic point of entry to the very advanced side as well as to the commercial.

Plastic 3D printing In the 3D printing sector, the plastics are no more utilised, just so that they can prototype something. Rather, they are deployed to the sophisticated manufacturing procedures which produce full working, impact resistant constituents, medical equipment, aircraft constituents and consumer products. This form of printing is now open to all the interests; the hobbists too and the industrial manufacturers; this has been made possible by the flexibility of the plastic materials that are used, and the technology that has been developed to print in 3D.

Understanding the Fundamentals of 3D Printing Plastics

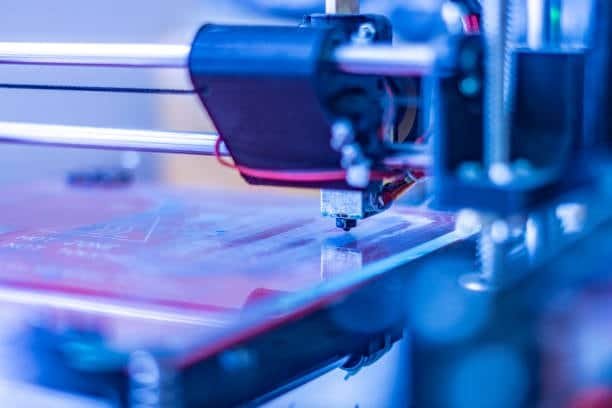

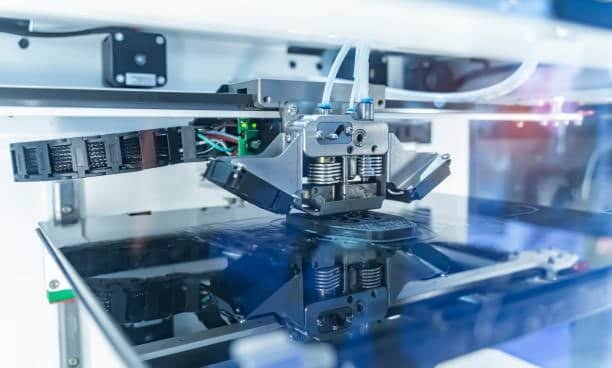

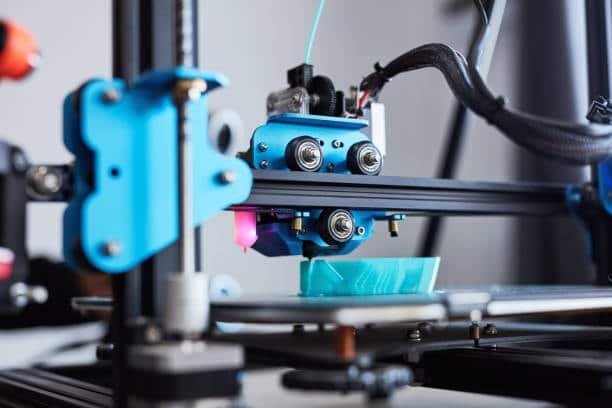

The technology of additive manufacturing relies upon 3D printing plastics. The layers of these good temperature resistant thermo plastics are heated up to their melt point and then transported through a nozzle after which they cool and solidify layer by layer into three dimensional objects. The procedure requires a precise temperature setting and an ability to accurately stick the layers and reprinting values of every particular plastic.

The principle of the method of plastic 3D printing is the assumption of solid filament into molten form and closely-measured plastering and rapid solidification. This heating procedure ought to be controlled adequately because it controls the adhesion of the layers, the dimensional property, and the type of surface. Other high performance plastics are having semi crystalline structure and have different thermal properties; hence require special temperature regime, cooling conditions and environmental effects to achieve optimum results.

Contemporary 3D printers to control the extrusion temperature to a more specific level allow advanced heating system, temperature sensors, and temperature control algorithm to fulfill necessary tasks. The extruder is the device that forces the filament in force present one after another at a particular pace and the molten material present in the heated nozzle before placing it. It includes determining rates of flow of materials and the way it changes with viscosity as the temperature changes and the way speed of printing a layer influences its quality.

PLA: The Gateway Plastic for 3D Printing

The most popular 3D printing plastic so far is the polylactic acid (PLA) since it is the simplest to deal with, biodegradable and offers the highest quality of the print. Given that PLA is a widely renewable-based thermoplastic based on a renewable fuels corn starch and sugarcane, it offers an eco-friendly alternative of petroleum-based plastics because it maintains the excellent qualities of printability.

The PLA is also printed at a relatively low temperature range of about 190-220 C and it is compatible with even the simplest 3D printers. The shrinkage rate is low and the warping tendency is very low producing an exact product in hands of a novice person, who tries to understand the principles of 3D printing. It clings very well on varied building materials like the glass, PEI sheets, and painter tape, and in most cases we do not require having warmed up beds, which proves its waterproofing abilities .

The versatility that is possessed by the PLA does not only encompass the basic properties of printing. Other properties of PLA like high temperature resistance and also greater flexibility and impact resistance have already been commercially manufactured by the manufacturers. It is used to produce special aesthetics and functional performance through wood fibers, metal particles, or carbon fiber components in specialty PLA formulations as they are perfect on decorative items.

The variety of color offered in PLA is approximately limitless with normal solid colors and non clear, color changing and metallic compounds. Diversity of this material, in its turn, predetermines the increased attractiveness of PLA to decorative objects and training models as well as make prototypes where the looks are as crucial as functions.

ABS: The Durable Workhorse of 3D Printing

Acrylonitrile Butadiene Styrene (acrylonitrile butadiene styrene) is the 3D printer-readable industrial option of robust products. The petroleum thermoplastic possesses very good mechanical properties and the ABS thermoplastic has good impact strength and are flexible and resistant to heat up to 80o C and this property makes them very common in the manufacture of aesthetic products in the automotive industry, electronic and consumer products.

The ABS will require a higher temperature to print as compared to the PLA ABS, at least as far as extruder temperature is concerned (ABS ABS is typically printed at 230-260 C), and at least it comes to the heated bed (typically printed at 80-110 C). This characteristic (warping, shrinkage) demands that the material be denoted skillfully in so far as thermal control is concerned and this means closed printing environments. Regardless of these challenges, ABS is able to compensate effectively trained users with shock absorbing elements which are very strong and functional.

Other plastics also do not match with the ABS in regards to post processing capability. Using standard woodworking devices, it is painted, drilled and tapped, sander and welded. The comfort of glass or finishing a surface does not contain any taste of layers and produces a professional like finish by the top of acetone vapor. ABS properties make it appropriate to prototype and end-uses, especially in place of traditional manufacturing methods.

The other advantage of ABS is that through the squeak-resistance, it is also chemical resistant and therefore can be utilized in an environment that exposes it to oils, light acids and variety of solvents. These qualities do not vary under a high magnitude of temperature, and, so, it can be used in the extreme conditions accurately with the broad temperature alongside the harsh areas, thus, it will be suitable in the top areas of lightweight parts .

PETG: Combining Strength with Printability

Sandwiched between the convenience of use of PLA and the mechanical characteristics of ABS is the Polyethylene Terephthalate Glycol (PETG) that seals the divide. It is clear glossy and high power plastic which is of good impact resistance as well as, resistant to chemical action and easy to print with relative simplicity with the benefit of good pliability as well as with ease of printing as compared to the other plastics since, the plastic relates to effective chemical processes. PETG is increasing its presence as a working component, and in transparent requirements.

The print temperature of PETG is 220 – 250 o C and there is minor warping and insignificant layer adhesion. Its bed temperature requirement is moderate and at 70-80 o C and it produces high tensile strength and flexible nature with good surface finish products. Unlike the ABS, during the printing process PETG does not emit any toxic fume, this is the best solution to use in an office and house environment particularly in configurations that use multiple extruder printing machines.

PETG is clear so it can be applicable in activities where the internal part, light guides, or decorating material ought to be visually inspected. When printed with optimal settings, PETG can be nearly transparent, and can look nearly as good and injection-molded parts.

The property of chemical resistance of PETG can be used in the application of the material in food entirely with consideration given to special grades and printing conditions. It is resistant to most of the common chemicals used in the powder segment and it does not interact with the cleaning agents and light acids.

TPU and Flexible Filaments: Bringing Elasticity to 3D Printing

Elastic filaments like Thermoplastic Polyurethane (TPU) provide rubber-like properties and elasticity to any project in 3D printing. The products enable them to manufacture gaskets, phone covers and shoes among others which require flexibility and absorbing impacts interest of big businesses.

The malleability of the printing filaments which is prominent in it requires the special printing technologies and changes in the printers. It is also appropriate to bendable materials to be directed towards direct drive extruders, as the difficulty of the compressions and feeding will be reduced since the filament will occupy a shorter way. The speed of the print needs to be reduced drastically, typically to 15-30mm/s, to prevent jamming, to extrude reliably in fused deposition modeling.

The ratings in shore hardness classify bendable filaments with shore A ratings falling on a spectrum of soft rubber-like (Shore A 70) and semi-rigid plastics (Shore A 95). The range allows the designer to make decisions on choosing materials which have definite cut flexibility value in case of particular applications. The soft ones are handled with even more care when it comes to printing them and are to be printed more slowly yet when it comes to flexibility it is far superior better and shock absorbent.

Due to the increasing quality of utilized materials and printing techniques, the future of the flexible 3D printing content is becoming stronger. Specialty of the properties of the elastomeric 3D print material has already been used in the manufacture of medical equipment, car parts, and accessories of consumer electronics, and in any sporting goods.

Advanced Engineering Plastics for Specialized Applications

High-performance engines plastics bring 3D printing in the harsh industrial use. The materials which offer strong mechanical properties in terms of strength, heat and chemical compatibility include PEEK, PEI and carbon fiber reinforced composite materials in the field of aerospace, medical and automotive industries.

The plastic that can show its best performance on 3D printing is polyetheretherketone (PEEK). High value parts of aerospace and medical industries could be produced using PEEK with high chemical resistance, and capable of operating at temperatures up to 250 o C. However, PEEK printing is impossible to perform on regular machineries, however, PEEK must be printed on special machineries whereby chambers are heated more than 400 o C.

The carbon fiber reinforced plastics consist of the printability of the base polymers and strength and rigidity of the carbon fiber reinforcement. Such additive manufacturing composite materials can be near the performance and machined aluminum with the design ability of additive manufacturing. These applications are focused on drone system platform, automotive solutions, and industrial equipment.

Polyetether imide (PEI) is also a good flame retardant and possesses well aerospace and electronics mechanical applications. It is hot printing, a large temperature range of -10 to 400F, very good dimensional stability and chemical resistance so ideal in the harshest of industrial environments.

Printer Settings and Temperature Management for Plastic Materials

Proper printing of plastics involves management of many temperature zones and of the surrounding conditions. The different available materials require varying requirements an extruder temp, bed temp, chamber temp and cooling fan which will produce similar results.

The temperature involved in the extrusion proceedings directly affects the material routine, the attachment of layers and the poor quality of the shoe. Temperatures that are not hot enough will cause under-extrusion and non-bonded layers as much as those that are very hot will cause stringing, oozing and inaccurate dimensional accuracy. Each of the plastic material possesses a balanced temperature range and should be determined through tests and calibration.

Even the temperature of bed is useful to prevent warping since it will make the first layer to remain molten as long and hence it can be stuck easily to the build platform. Peculiar to different materials, some plastics will bolt on unheated beds, and on others higher temperatures above 100 o C may be necessary to stick.

The rate of solidification of extrude is controlled by the regulation of cooling fan. There are plastics whereby aggressive cooling is required in order to prevent the aspects of droopiness and through this it is able to bring enhancement to the aspect of the quality of surface and there are also plastics whereby minimal cooling is required so that the issues of the keeping of the layers appropriately attached and so that cracking does not occur.

Build Surface Preparation and Adhesion Techniques

Preparation of the build surface is the precondition of obtaining the first layer attachment and passing print no matter how simple it is. Other plastic filaments require some prepared surfaces and adhesion promoters in order to adhere the build platform during the printing.

Glass beds provide both good thermal conductivity and flatness though special adhesion aids may be required with certain materials. Borosilicate glass is thermal cycle resisting as it does not crack on thermal cycling as compared to regular glass that can crack by quickly heating up. Adhesion with other plastics is enhanced by such surface treatment as hairspray, glue stick or specific adhesives.

Good adhesion also achieves most plastics on to PEI (Polyetherimide) sheets without special treatment. The printing material also provides a good binding stability in the printing process, it is easily removable and hence it can easily be removed, and there is no actual damage that is caused in the removal of the part. Occasionally PEI surfaces are a little removed of isopropyl based alcohol in order to maintain adhesive properties.

removable-surfaced magnetic beds are now in demand this is attributed to its ease and congruent use. The good part about the systems is the ease to flex and file off parts on the build surface and the great adhesion through the print jobs. Different surface textures are most suitable in treating variety of materials.

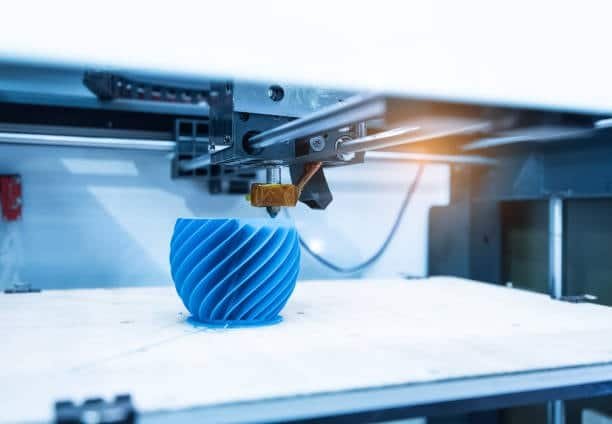

Layer Height and Print Speed Optimization

Layer Height and Print Speed settingsLayer heights are settings that set the structure of the filament, and so is the print speed. The print speed dictates how quickly the printer will print out 100 percent of the filament and this is one of the things that a designer should make before commencing with printing. Layer height is the size of the filament and the range of the height of the filament also depends on the size of the motor as per the motor design and one of the options which also a designer has to decide. Layer height The layer height is what the print will be high and is set by motor size and how fast the motor moves.

The speed at which it prints and the height upon which the layers will be printed will really have a big impact on the quality of the prints, mechanical properties as well as the time it takes to print. The relationship between such parameters could be known and the knowledge used to optimize them to achieve a particular application but with a trade off between the quality and production efficiency aspects.

The layer height creates effects on the strength of the layer adhesion, the surface finish and level of detail. The thinner layers will produce a smoother surface and detail by all means but will take a lot more time to print. The thicker layers will save on the print time at the expense of quality of surface and the feature resolution of small features renewable raw materials. Most applications can be covered by a high layer height with 0.1-0.3mm.

Quality of surfaces, dimensional terms and mechanically is determined by the rate of printing. Low production speeds are normally of good quality but they are not fast fiber reinforced materials. There is also need to delegate printing phases to slow and fast speeds- different printing phases can be delegated to slow and fast speeds to attain precision and fast speed can be assigned to create prototypes without jeopardizing the visible quality fiber reinforced materials powder form..

Jerk and acceleration are two settings that enable you to control the speed at which the print head is going to change speed and direction common soluble filament materials. Vibration is reduced by acceleration well-tuned and improves the quality of the surface in fused deposition modeling, particularly the details features and on overhangs fiber reinforced materials. The greater is the superior quality achieved, the more retrogressive settings worsen the print time manufacturing process.

Support Structures and Overhang Management

Support structures enable the use of complicated geometries that have overhangs, bridges and suspended elements automotive sector. This will limit the amount of wastage of materials to produce and print in a successful manner by knowing when to use aids and how they can be placed most effectively market growth major companies.

The 45s rule: The 45-degree rule provides a crude guideline to what tends to require support: that overhangs, above 45-degrees, most commonly require support not to slacken and distort layers. However, this rule is being added individually to the properties of the material, cooling, and the implementation of the setting of the printing speed.

Support selection of the material impacts the part quality and after-processing requirements withstand high temperatures. Blend well with the part, but it is important to take it out carefully without destroying same media. PVA or HIPS Soluble supports can enable final separation to be done cleanly but require dual-extruder printers, and combinations of materials fiber reinforced materials.

The approach to support structure is in a balance between printability and removal. The settings of an appropriate gap will allow the support removal without damaging the part surface whereas enough support area will ensure that the printed part is supported adequately. The tree support pattern and the organic support pattern take less materials and works excellent mechanical properties.

Post-Processing Techniques for 3D Printed Plastics

After the post processing 3D printed anatomical models are ready to be positioned and stand as the eligible products with improved overall appearance, functionality, and durability good temperature resistance. The different plastic materials also respond in different ways to the finishing procedures and this provides an alternative of making judgement about the surface texture, the strength and the aesthetic values thermoplastic widely.

Sanding, filing and drilling has to do with mechanical finishing so as to be accurate in the sizes as well as the quality of the surface. As one goes through the steps of grit sand we have a progression of constant smooth finish between coarse grit to fine grit giving us the smooth surfaces that can be painted or can be coated. The rate of working will be enhanced through the adoption of power tools, and care should be taken to ensure that they do not damage through heating and change of dimension low cost.

Chemical smoothing involves the application of solvents in partial dissolution of layers of surfaces and create glass-like surfaces. Acetone vapor treatment is admitted into ABS quite readily however other material requires the use of different solvents and precautions similar properties. Specified exposure duration and temperature prevent the tendency of excessive elution and maintain dimensions.

To some materials, it is possible to relieve certain internal stresses and improve mechanical properties by heating treatment. PLA can be heated to higher temperature Melts of reproducible PLA above 35 C are more crystalline and thermally resistant, and careful temperature and time control is required.

Quality Control and Troubleshooting Common Issues

The outstanding systematic troubleshooting mechanisms and preventative maintenance should be used in realization of uniform quality in 3D printing process. By examining common failures and reasons thereof, the speed of attacking problems and raising their success rates will become high.

The layer adhesion problems manifest themselves as delamination, crack or non-adhering parts. Some of the factors include the wrong temperatures, the wrong leveling of the bed, unclean work surfaces, or undersalting of the materials. Systematic diagnosis involves a process of checking up on all the variables systematically to determine the primary cause.

The issues causing dimensional accuracy are founded on the concept of thermal expansion, shrinkage of material or mechanical issues. Calibration activities can guarantee axis movements, rates of flow of extruder and accurate temperatures. The repairs that are done periodically put a stop to the gradual fading that disrupts quality of prints.

Layer lines, roughness or inadequate extrusion of the surface quality are the types of problems normally attributed to the mechanical issues, material inequalities or to the environmental factors. Vibration dampening and belt tension and work of materials that can stand under high temperature is observed to produce good quality surface finishes as regards holding the materials homogenously in storage.

Industrial Applications and Manufacturing Use Cases

Plastics used in 3D printing that were initially regarded as prototyping materials have in certain of the industries turned out to be production solutions of end parts. Successful application as perceived indicates the direction that appropriate material selection should be made towards the development of the process to commercial production.

Strong weight characteristics of materials as well as thermal resistance and regulation of materials used are put to test by aerospace products. PEEK, carbon fiber composites and specialty resins are the composites that may be used to make cabin parts, ducting and non-critical structural parts and these composites show a significantly greater degree of weight savings.

It is advantageous to use biocompatible materials and properties of customization in relation to medical device manufacturing. Implants that are patient-matched, surgical guides and prosthetics are highly regulated, but take advantage of the freedom of design associated with 3D printers.

The 3D printed plastics also find their used in prototyping, tooling and low volume manufacturing parts by Carmakers. Functional parts that can withstand the automotive environments and reduce the cost and development time can be developed using engineering materials like the ABS, nylon and carbon fiber reinforced material.

Environmental Impact and Sustainability Considerations

The entire environmental implication of the processes of the 3D printing is varied depending on the choice of a material, technologies of manufacturing, and the fact of the final destruction of plastics. The consciousness of the sustainability matters dictates the conscious choice of the materials and reduction of the wastes.

The use of biodegradable raw materials like the translucent filament has a positive environmental implication as the raw material is renewable and complies with the term of composting it under the right conditions. However, biodegradation can only take place when the industrial composting plants and home composting can never attain high temperatures to ensure they are degraded.

The challenge to 3D printing of plastic recycling is contamination, wear-out of the plastic and sorting problems. The others can be recycled as a mechanic by shredding and re-extruding, and some of the materials require chemical recycling to obtain base materials.

The summaries of the circular economy approach focus on the disassembly design, material recovery and material reuse. The closed loop systems reprocess the wastes thereby resulting in a reduction in the consumption of virgin materials and wastes at the product phase.

Future Trends and Emerging Technologies

The components of the future of the 3D printing of plastics are advanced materials, processing and increased applications. The newer technologies give the promise of adding on to the existing abilities and there are new frontiers to follow on in the area of additive manufacturing.

The scope of multi-material printing has opened the gates to the mixing of the properties of plastic into smaller portions. Gradient materials pass on levels to an extent of varying hardness to softness and embedded electronics create smarter materials with in-built sensors and actuators.

Recycled and bio-based feedstocks are less environmentally degrading and possess an equivalent list of performance attributes. The waste plastic retrieval systems produce 3D printing to filaments and the agricultural wastes are an unwanted inventory of materials during the production of bio-based polymers.

Recycled and bio-based feedstocks are less environmentally degrading and possess an equivalent list of performance attributes. The waste plastic retrieval systems produce 3D printing to filaments and the agricultural wastes are an unwanted inventory of materials during the production of bio-based polymers.

Material Selection Guidelines and Decision Frameworks

The process of choosing plastic material suitable to apply during 3D printing should be done systematically by carrying out the assessment of performance requirement (performance need), processing restrictions, and cost. Emerging numbers of available materials are being addressed with the help of decision frameworks.

The process of choosing plastic material suitable to apply during 3D printing should be done systematically by carrying out the assessment of performance requirement (performance need), processing restrictions, and cost. Emerging numbers of available materials are being addressed with the help of decision frameworks.

The mechanical property requirements are strength, flexibility, limitations, impact and the fatigue life. Understanding of the load condition, environmental exposure and the modes of failure will help in choosing the materials that will meet or even improve the performance it is aimed at.

Cost analysis of the described article consists of the material, processing costs, failure rate and processing requirement. The total cost of ownerships can prove to be tremendously different than the raw material cost and to an even higher degree, on more complex geometry shapes or higher performing materials.

Advanced Printing Techniques and Multi-Material Systems

Advanced 3D printing technologies introduce extended possibilities of design and activity with the help of innovative techniques of interacting with the material and depositing it. These technologies enable it to produce complicated items and multi-purpose components.

Massive printing of various materials is possible through having a two extruder structure to produce objects of varied characteristics or multi functional support structures. The physical property match can be achieved by matching colors present in the mix, gradients, and embedded material can be achieved through controlled deposition of materials.

Continuous fiber During printing, fibers which are highly resistant are impregnated throughout the plastic body. The process enables making of composite components with extraordinary strengths and stiffness with the still-considerable design flexibility of additive manufacturing.

The in-situ monitoring systems install cameras and sensors on the locations of detection to monitor defects and spots in the prints in real-time. The data transmitted by the sensors can be used by the machine-learning techniques to predict the failures and automatically adjust the parameters of the printing, thereby raising the Samsung probabilities of

Safety Considerations and Best Practices

Protective measures Material hazards, ventilation and personal protective equipment to use must be known when working with 3D printing plastics. Different materials possess similar characteristics but different hazards that are achieved through adherence to efficient procedures and equipments.

Thermal hazards such as using hot parts and melted plastics require a safety approach and safety measures. Safety precaution and awareness will prevent burns on hot surface, in extruder, or build platforms, and others.

Certain plastic products 20give out chemical fumes which ought to be cooled down and purified by fresh air. Enclosed printers with filtration systems located in a closed room guarantee that operators are not exposed to injurious fumes released during the printing processes and at the same time facilitate the most favorable environment required in the process of carrying out the activities of printing during production of the products.

Fire safety plans involve good electrical works, heat protection plans and emergency measures. A runaway heating condition can wreak fire hazards, and it must be prevented by ensuring careful designs of the equipment and monitoring systems.

Анализ затрат и экономические соображения

The cost economics of doing 3D printing plastics involves consideration of the cost of the material to be utilized, the nature of the equipment involved to be installed, a matter of labour involved and even comparison of prices in relation to the more traditional forms of production.

Meanwhile, the price of ordinary and advanced plastics is quite different and specialty types of engineering plastics are expensive. The process of waste reduction recycling programs helps improve cost effectiveness of the production applications when using volume discounts.

The expenditures on the equipment involve the costs of the printers, the necessity to carry out maintenance, and the rearranging the facilities. Justification of costs incurred in capitals should be based on the calculations of the returns on investment based on volumes of production, complexities of part and alternative cost of manufacture.

The producers of the 3D printing devices will also need some labor force to run the machines, post processes and quality check these products. The automation advantages and the capabilities cover the costs and the overall production of the commercial intentions.

Global Supply Chain and Logistics Considerations

Supply of 3D printing materials is international business, which is why one should know the foreign regulations, shipping regulation and supply chain risks. Logistics partners are essential in the selective laser sintering in terms of quality and material availability.

The 3D printing materials and equipment have professional logistics services of Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide). GWT is a business logistic company and a global freight forwarding and supply chains solutions provider, who offers air freight, sea freight (China Europe railway freight), intercontinental express, and China Europe railway freight. Their shipment and custom clearance, warehousing, and Amazon FBA experience is incredible, which implies that they can provide the 3D printing supplies worldwide. With the aid of its global network of trusted partners and the latest technological tools in the sphere of logistics, GWT makes it possible to transfer the material manufactured by the manufactures to the final users without wasting time and effort, controlling the quality and compliance indicators.

A number of regulations governing the exportation of plastic materials into the international market exist which relate to the classification of the potentially-hazardous materials, packaging and documentation of such an exportation. Some rules to consider in the import of plastic materials in the various countries exist and these affect the shipping practice and the cost in general of soluble materials by the filament.

Transport quality must support good packaging skills, temperature and handling. When moisture is absorbed into a material, when a material is subjected to thermal cycling and when a material is subjected to mechanical incursion, moisture absorption, thermal cycling and mechanical incursion can compromise its material properties and these issues must be managed effectively in the supply chain.

Заключение

There have been variations in the possibilities of manufacturing because of the adaptability, the performance, and the accessibility of the 3D printing plastics. Be it, simple PLA prints to the most sophisticated engineering materials, the range of choices continue to expand to serve a multitude of application needs. In order to be successful in 3D printing, there are various aspects of knowledge that should be grasped and parameters that should be optimized and in that other way high performance polymers after quality control measures.

The future stage of plastic 3D printing is promising due to the possibilities of additional work with materials and processing as well as expansion of possibilities of use. This number of industries will adopt it due to the nature of the materials that are sustainable, the speed of processing and the multi functional nature which all deal with the problem of the environment. As the technology matures, good logistic support and supply chain management is becoming very important issues in order to facilitate the continuity of good quality and availability of materials in any part of the world.