Введение

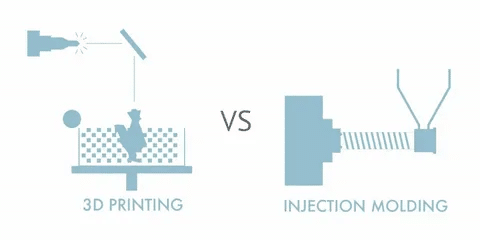

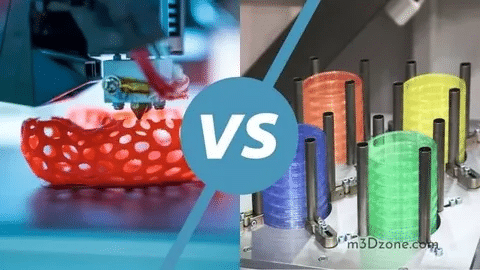

Nowadays, fast-changing conditions of manufacturing provoke a problem of a production method selection determining the success or failure of projects. Among the most visible manufacturing technologies (3D printing and injection molding), each can be beneficial in its own way: it all depends on your particular needs. The basic difference between the processes is very essential to make informed decisions, which affect cost, quality, timeline, and scalability.

What Is 3D Printing?

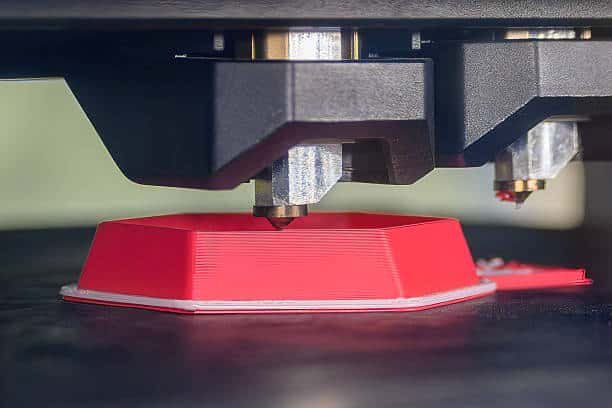

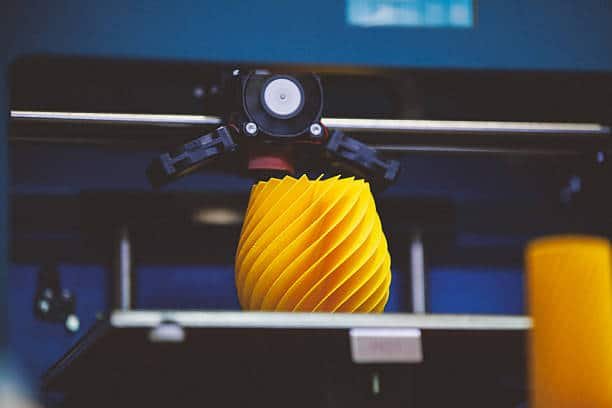

Additive manufacturing, which may also be referred to as 3D printing, involves designing objects by constructing a few layers on top of other layers to end up with a complete object. This is a radical technology and its technology constructs parts out of different materials such as plastics, alloys/metals, ceramics, and composites directly via CAD files including brape. The process removes the necessity of conventional tooling, making it suitable for manufacturing fast prototypes and small runs.

3D printing forms Popular 3D printing technologies and include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). The possibilities of each of these methods are unique when it comes to the material compatibility, surface finish, and compliance with the dimensions.

What Is Injection Molding?

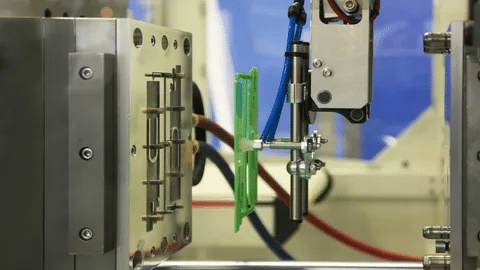

Injection molding is an already mature manufacturing process with parts formed by injection of molten material into well engineered molds. This is a subtractive method of manufacturing that uses customized tooling but it is very productive in mass producing identical parts with high productivity, with excellent consistency and quality.

There are many important elements in injection molding the machine, and they are the injection unit, clamping system, mold assembly, and control systems. In Zecheng Precision, we produce high-precision mold parts with the tolerance of as ±0.001 mm and manufacturing high quality high parts and dimensional tolerances.

Cost Comparison Analysis

Initial Investment

The investment involved in 3D printing is very low considering the fact that the desktop printers cost a few hundred dollars to the cost of industrial systems that can reach thousands to hundreds of thousands. Tooling cost is very high, especially in the beginning, and high precision molds can easily cost anywhere between 10,000 and 100,000 dollars or more depending on the level of complexity and precision mandated.

Per-Part Costs

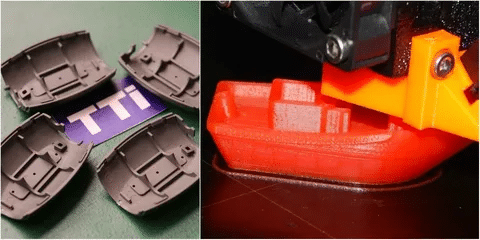

In the case of low numbers (1-1000 parts), 3D printing can be more cost-effective as tooling prices have been removed. Nonetheless, injection molding cost per part is significant when volumes are high. At an outsource operation it would generally take 1,000-10,000 parts to reach a break even point depending on material requirements and complexity of parts.

Long-term Economics

High end production volume is best served through injection molding according to the long term value. Well maintained precision molds are capable of creating a large number of parts that are consistently high quality, in the millions. 3D printing is still cost efficient when dealing with low-volume high-variety scenarios.

Speed and Production Timeline

Prototyping Speed

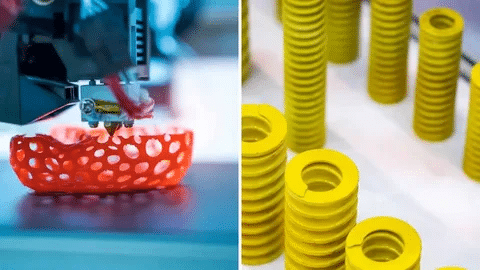

Rapid prototyping is one of the strengths of 3D printing, and designers can build prototypes without waiting long tooling times to change or repeat the product. Basic prototypes can then be made within a few hours to carry out design confirmation at a quicker rate and expedited time-to-market.

Production Readiness

Injection molding necessitates a long lead time of mold design, definition, production as well as testing of the mold, 4-12 weeks normally being the lead period of precision tooling. But after the production starts injection molding is capable of producing thousands of parts per day compared to 3D printing that is up to its capacity.

Scalability Considerations

3D printing is linear in scale- to scale manufacturing, time needs to be doubled and machines as well. Injection molding has scaling benefits that are exponential since even the one-mold tool can produce parts 24 hours a day with little labor employed.

Quality and Precision Standards

Dimensional Accuracy

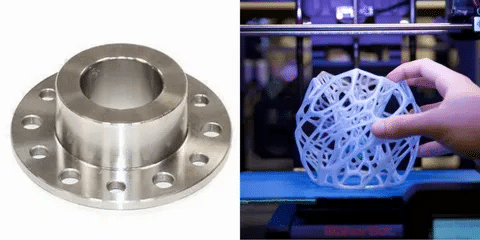

Contemporary injection molding is extremely accurate and tolerances are usually maintained on critical dimensions within the order of 0.001 mm. The high-precision parts that we produce with our precision mold components at Zecheng embrace coaxiality of 0.002 mm and roundness of 0.0015 mm, and they are applied in automotive and medical situations.

Accuracy of 3D printing also depends considerably by both technology and applications used. The ±0.1-0.3 mm error level of FDM printing can be obtained with the accuracy of SLA approaching ±0.025 mm (small objects).

Surface Finish Quality

Injection molding allows producing high quality surfaces directly out of the mold and may obviate the need of any post-processing activities. With the proper designing and manufacturing methods, Ra 0.025 values of the surfaces can be reached.

Post processing Adding time and cost to the production procedure, 3D printed components usually need extra processing that smooths the parts. The typical features are layer lines and support marks that need finishing.

Material Properties

The parts made by injection molding are characterized by better mechanical properties since material flow and molecular orientation is optimized in the process. This leads to components that are strengthened, durable and with improved performance characteristics.

Weaknesses of the layer boundary may arise in 3D printed parts since it is anisotropic because of the layer-by-layer structure. Still, higher quality 3D printing materials are getting better in terms of mechanical strength.

Material Selection and Compatibility

Available Materials

The injection molding process accommodates a very wide variety of materials, such as engineering plastics, elastomers, metals, and proprietary compounds. The wide compatibility makes it optimizable to suit certain functions including automotive-grade plastics and biocompatible medical materials.

The selection of a material used in 3D printing is still additional or narrower than that of injection molding. Technical 3D printing materials, however, bring some special properties such as dissolving supports, elastic rubbers, and metallic-loaded materials.

Material Performance

Materials used in injection molding have well defined supply channels and tested results have been documented which gives the material predictable performance attributes. Most injection molding materials have well documented long-term material stability and performance.

The performance of 3D printing material might possess more limited information, especially in emerging formulations. Nonetheless, the fast moving progress of materials is still widening what it is able to accomplish and what it is capable of using.

Design Flexibility and Constraints

Geometric Capabilities

With 3D printing, the freedom of design is unprecedented, and permits complex internal geometries and lattice structures as well as consolidated assemblies, not possible with conventional manufacturing techniques. This functionality enables creative designing and integration of functions.

During injection molding, it is important to consider draft angle, undercut and parting line in the design. Nonetheless, with the proper planning and investment, complex geometries are achievable with advanced steps having been taken up in mold-making techniques and multi-cavity designs.

Design Optimization

The ability to print in 3D allows the quick iteration and improvement of designs without the need to change the equipment. Physical tests of different versions can also be performed by designers, to optimize performance prior to locking down final versions.

DFM analysis is an advantage in injection molding as it allows producing maximum efficiency in manufacturing and design of parts. Zecheng offers all-inclusive services regarding DFM in making designs injection molding-successful.

Industry Applications and Use Cases

Automotive Industry

The injection molding is considered the dominant technology in automotive manufacturing by ensuring that millions of identical parts with the same quality can be obtained through it. The precision needed with connector molds, interior parts, and under the hood parts are what injection molding offers in the form of durability.

The use of 3D printing within the automotive sector is in the use of quick prototyping, low-volume, specialty, and tooling support parts. Designs availed by 3D printing capacities include custom fixtures, prototypes and end-use parts of limited-production vehicles.

Medical and Healthcare

The two technologies have made important medical uses. Injection molding is used to make large volume medical equipment, drugs, and precision parts that demand regulatory approvals regardless of their use and performance.

It is starting to deliver personalized medical devices, surgical guides and body parts through 3D printing. Difficult medical applications make use of precision capabilities and biocompatible materials.

Бытовая электроника

Injection molding is of importance to the electronics industry since it creates housings and connectors as well as precision components. Micro-molding facilities allow manufacturing of the smallest components in high quality precision and reliability.

Electronics applications are supported by the 3D printing, which is used in prototyping, custom enclosures, and special needs parts that are specific to the niche or products that produce in small quantities.

Environmental Impact and Sustainability

Material Waste

In 3D printing, there is very little wastage of materials, in fact, just what is needed to make the complete part and supports. The additive process minimizes the burden on the environment and lowers the cost of materials used in a complex geometrical structure.

Runners, gates, and rejected parts are the injection molding processes that cause wastes. Most thermoplastic wastes however are recyclable and reusable with minimal effects on the environment in large scale productions.

Energy Consumption

The energy consumed in the process of 3D printing is dependent on the type of technology and complexity of the part, the latter defining the amount of support material. In most cases, energy use per part is reduced as density of build and part consolidation is increased.

High or medium volume injection molding is often cheaper per part in terms of energy consumption, the cost of energy being spread over many parts. The current injection molding machines include the use of energy saving methods and systems.

Future Trends and Technological Developments

3D Printing Advances

New technologies such as multi-material printing, accelerated printing speeds, and enhancement of material quality are in the process and continue increasing 3D printing applications. Some applications are challenging traditional manufacturing procedures and now industrial-size 3D printing systems are coming to challenge them for use.

Injection Molding Innovation

Injection molding has been advancing alongside exotic materials, high precision tooling and robotic integration. Fourth-generation industries help in real time tracking, proactive servicing, and quality improvements.

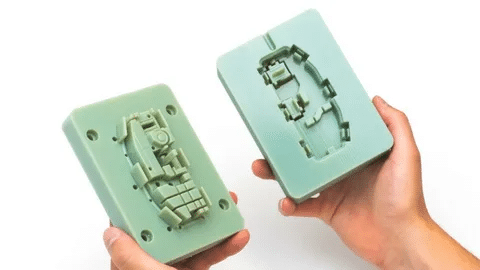

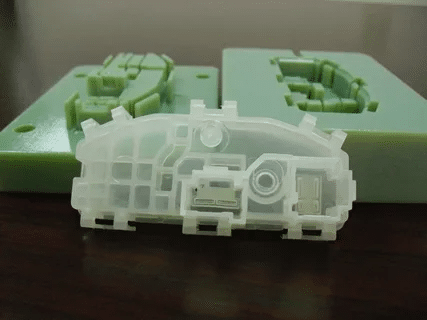

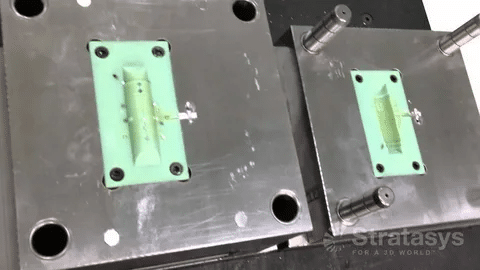

Hybrid Manufacturing

The combination of both technologies is being carried out by innovative manufacturers in which the advanced features of mold features, conformal cooling channels and rapid tooling solutions have been carried out through the 3D printing of the injection molding.

Making the Right Choice for Your Project

Volume Considerations

3D printing tends to win in low-volume small-scale manufacturing (1-1000 pieces) because it decreases the tooling cost crucial in fabricating all products, as well as reduces time-to-market. Injection molding is often more economical than other methods and produces more parts per hour in a 10,000+ parts production cycle.

Quality Requirements

Injection molding is normally preferred in places where the application demands close tolerances, high fidelity finishes on the surface, and uniform mechanical properties. Projects that are more focused on the complexity of the design and fast iteration are potential users of 3D printing opportunities.

Timeline Constraints

3D printing is likely to be more suitable to projects that have a short term production requirement or where prototyping is required immediately. Injection molding is scalable and efficient when applied on long-term production projects where the designs are fixed.

Заключение

3D printing or injection molding is a useful method based on its own merits, and each has its areas of specialization. These technologies have their differences which may lead to selection depending on various parameters such as volume of product to be produced, quality of product to be produced, time frame and budgetary issues.

Injection molding is still the best in such a high-volume production that needs extreme precision and consistency of quality. Firms such as Zecheng Precision are involved in the supply of the precision mold components that are required in the attainment of the world-class injection molding outcomes.

The 3D printing industry still has a long way to go, furthermore, it presents exceptional potential in case of quick prototyping, low volume manufacturing and intricate geometry needs. As both the two technologies keep on developing, manufacturers have an advantage to know the limitations and advantages of the technologies so that they can make effective decisions to optimize their production strategies.

The future of manufacturing may see a smart combination of the both technologies, which can be used manually in order to make the production systems more efficient, flexible, and able. Learning the possibilities and shortcomings of these technologies, manufacturers will be able to make decisional steps that will foster success on the current competitive market.