It is no longer a luxury for manufacturing to Precise, Fast, and Long Tool Endurance, these are necessities when it comes to manufacturing in the twenty-first century, including considerations for tool life . Dynamic machining is another method that has had considerable impact on job operations through an advanced cutting approach, particularly in terms of tool engagement. that incorporates toolpaths, chip load, and chips involvement to achieve incredible machining. Milling with dynamic cutting velocity not only reduces time for cutting but also helps in cutting without causing much wear and tear to tools as well as offer smooth surface finishes even on complex materials.

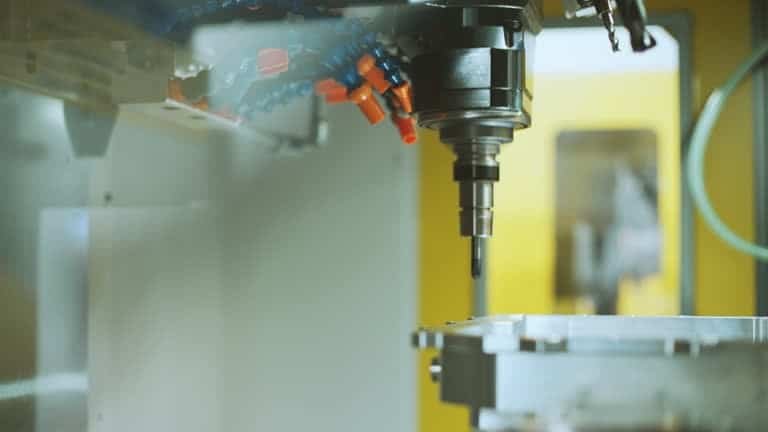

What is Dynamic Milling?

Milling at high speeds is said to be the most efficient way of removing material and achieving favorable cycle times and material removal rates, utilizing the dynamic milling strategy . through consistent tool interaction while maintaining an optimal cutting speed and an effective milling strategy . In addition, while in conventional milling, the cutter may periodically interact with the workpiece at random places, dynamic milling features a consistent radial width of the cut while changing the path of the tool to eliminate possible overload, ensuring consistent feeds throughout the process .

This usually involves dynamic tool paths that are computer aided manufacture which involves smooth arcs rather than sharp lines and takes into account the flute length . These continuous motions help to control chip thickness level great, manage the sudden changes in directions, and prevent any force build-up constantly. This means that the stress and heat put on the cutting tool is lower, resulting in less stress during the machining process and better management of chips . and the heat created during the machining process is dissipated over a larger area and time thus increasing the tool’s durability.

Key Characteristics of Dynamic Milling

Dynamic milling is characterized by a small radial depth of cut and a greater axial depth of cut which gives deeper cutting action while considering axial engagement and allowing for the removal of more material. ithout significant lateral contact. It also allows for minimizing the amount of the cutter surface in contact with the corners of material at any given time thus minimizing the cutting force and heat build up.

Another feature of this method is the ability of adaptive tool path in which the software controls the direction in which the cutter travels in order to avoid sharp edges and other obstacles which reduce the cutting angle.

It also has high spindle speeds and feed rates as claimed in the case of dynamic milling, which often benefits from appropriate coating . The possibilities of running the tools at higher speed with better load control meant that jobs were able to be completed in much less time than through typical usage, contributing to the overall success of dynamic milling by significantly reducing cycle times . , thus retaining the surface quality and increasing efficiency .

Benefits of Dynamic Milling

Another advantage of dynamical milling is the increased durability of the tool, particularly when using end mills . This means that shock is prevented and its effects such as blunting of cutting edges are controlled thus the cutting edges can go on for a long time before they become blunted, especially when machining titanium ultimately extending the tool life. . This results in better tool design leading to less frequent tool change, decreased down time, and less tooling expenses all around.

On productivity, it rises to the occasion as well as offers significant improvements, especially when working with steel material . They also provide optimized paths and efficient high feed rates which decreases the cycle time and minimizes pressure, hence making it more suitable for shape-sensitive production. Furthermore, dynamic milling allows for greater depth of cut per pass which reduces the number of passes over a pocket or cavity, another potential gain in productivity.

From the quality aspect, the smoothness of the dynamic motion results in better finish and better parts accuracy, especially when working with aluminum . It is also important to note that reduced heat and force also have the benefits of reducing workpiece distortion especially for thin-walled or shape-sensitive components that may be sensitive to heat.

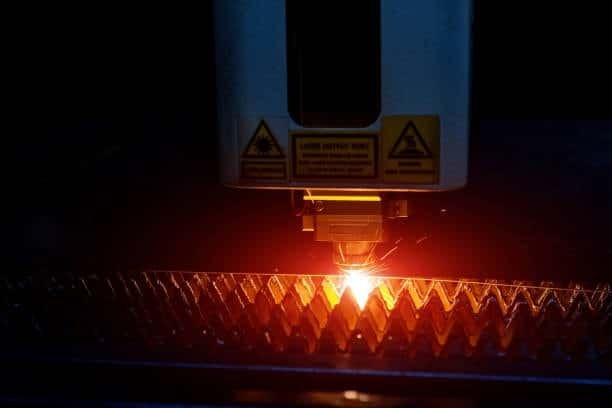

This is especially good for die and mold steels, high tensile strength steels, titanium, inconel and other hardened materials, as well as for various members that prove to be a challenge to other types of cutting due to the wear and high cutting force required.

Applications Across Industries

Dynamic milling is now extensively applied in aerospace, automobile, medical device production, mold manufacturing industries and other industries. For example in aerospace industries, geometries and the use of strong material make use of dynamic milling as a result of less tool wear and high speed during the machining process, which can be optimized through program adjustment . In mold and die work, where undercutting and undercut features are the order of the day, the method is quick and does not produce as much waste as other traditional cutting methods.

However, because it can quickly change between modes, the dynamic milling strategy is suitable for prototyping and other low-volume operations that require great precision but do not necessarily require high productivity. Thus, in contrast to mechanical changes, which offer fixed settings, parameters provide shops with flexibility to accommodate new designs and requirements, taking into account the unique challenges of each project, along with the implementation of precise code . .

Implementation Considerations

Getting to dynamic milling needs a little effort than just cam software and implementations, including proper tool selection. Classifying the machine, selection of tooling and work holding are some of the crucial tasks that are involved. This should be accompanied by high-feed operation, smooth movement of each axis, and proper code implementation as well as the availability of ample horsepower to effectively support and manage the chips produced. in the CNC.

Milling should have tools that can be used at higher speeds, and any guy in charge of the operation should ensure they are coated to prevent melting from heat. Also, the correct clamping is critical along with the feeds – any vibration during the operation means that all the advantages of dynamic methodology are void, potentially reducing effectiveness by half. .

Training is another key element, particularly in understanding the relationship between feeds, axial depth, radial engagement and the spindle speed . It is crucial for the operators and programmers to know the correlation between axial depth, radial engagement and the spindle speed, showcasing the versatility of dynamic milling. and the feed rate. Expending time to learn how to optimally set up these parameters shall ensure that a thorough exploitation of dynamic milling is achieved, ultimately extending the tool life .

Заключение

When every split second counts and where ERROR margin leaves room for no other options, dynamizing milling comes out of the equation as a key competitive weapon, establishing a crucial link between efficiency and productivity . It revolutionizes the traditional approaches to machining through smart cutting strategies, best toolpaths, minimized stresses on tooling and unification of multiple operations. For sectors that are keen on testing the envelope within materials and design, dynamic milling remains an ideal progressive innovation whose performance will correspond with increase in production. For any shop that aims towards optimization, such a technique is not a luxury but rather a necessity that must be in the shop, especially for applications with limited resources .