Know more about rapid injection molding and rapid injection mold tooling whether on prototyping that are a cost effective solution or production read parts. Find out advantages, technologies, and materials of rapid production.

The industrial environment has transformed into a whole new dimension, where mechanical engineering and speeding up the mode of production has become an unprecedented venture of success on the part of any company that upholds its product creation tasks. Such an innovative practice creates a middle-ground between conventional prototyping technologies and production molding, providing manufacturers with a method of total efficiency with regard to high precision cost-effective and efficient production components of high quality.

In the present competitive world, the key to the success of the business can be the rate of ahead of others in the market. This competitive advantage of rapid injection mold tooling is achieved due to its greatly decreased lead times as compared to the lead times taken by traditional injection mold tooling processes along with the quality and precision of rapid injection molded parts that can withstand higher molding temperatures, which is the hallmark aspect of the traditional injection molding processes.

What is Rapid Injection Mold Tooling?

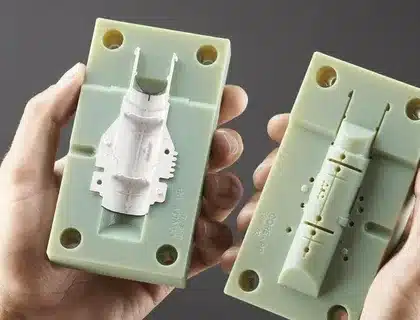

High-speed Injection Mold Tooling is an innovative production method suited to produce finished products quickly that increases production speed and injection molding precision and high accuracy while driving down the lead times drastically. In comparison with the standard tooling which requires about 12-20 weeks to be completed, rapid tooling provides functional molds in a short time scale of 2-4 weeks, thus speeding up the process of product validation and market entry into full production .

It involves the use of modern manufacturing technology, such as CNC machining, 3D printing and non-traditional tooling materials that allow for uniform cooling and efficient manufacture of production-level molds in an extremely compressed time period. The tools derived can manufacture between hundreds to thousands of components depending on the actual requirements and materials to be used for low volume production runs .

Over the last ten years the technology has grown up and evolutions in tooling materials, production methods, and techniques of design optimization have lead to increased durability and part quality. Using modern rapid injection mold tooling, the tight tolerances may be as good as traditional steel tooling but with the flexibility required in multiple design iterations as well as small electronic run quantities, which ensures the desired mechanical properties .

Key Benefits of Rapid Injection Mold Tooling

The benefits of the fast injection procedure of mold tooling are much more than the mere savings in terms of time and include strategic commercial leverage that can be a game changer in terms of product development strategy. One of the most convincing benefits is seen in competitive pricing and cost savings, where the typical cost of product development in rapid tooling is 30?70 percent cheaper (than traditional steel tooling), which means that shorter runs and verification of production parts can be affordable.

Acceleration of speed to market enables firms to rapidly respond to market pressure, test thoroughly, and make design change easily, and without jams caused by slow traditional tooling. The ability to respond quickly to changing needs of such industries or seasonal products through rapid injection allows real world testing and is especially cost effective.

Early validation or risk mitigation allows manufacturers to eliminate costly and time-wasting rework later in the process by finding and fixing design problems early in the work process, ensuring parts with excellent chemical resistance . Their capacity to manufacture working components to test and validate in the market immensely lowers the chances of incurring high costs to change the design at a later stage of development.

Design iterability gets supported by flexibility in which any number of complex molds and design variations can be tried and improved without being limited by the cost. Such iterative solution may result in final plastic parts that are much better, and also it can help identify optimization opportunities using bridge tooling, which would otherwise be overlooked.

Traditional vs Rapid Injection Molding: A Comprehensive Comparison

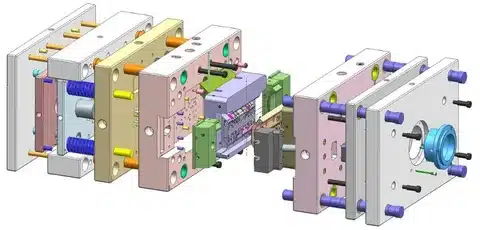

The gold standard of high volume injection molding with harden steel molds at millions of inserts or decades of service life has traditionally been with traditional injection molding. These tools, including traditional steel molds, have a lot of machining, heat treatment and finishing and this sometimes can span to months before the lead time can be achieved also they also need a lot of initial investments involved.

Rapid injection molding does not have the long life time as its main objective because it values speed and flexibility more than durability, and instead makes use of materials and procedures that are designed to allow faster and cheaper manufacturing. Whereas the standard molds may yield millions of pieces in their span, the rapid tools usually aim for uniform wall thickness at thousands to tens of thousands of cycles, which also coincides with the requirements of prototyping, low-volume production and market testing, often using a master unit .

Approach, the nature of material involved in traditional approaches such as molding, involves hardened tool steels and exotic alloys, whereas rapid tooling makes early use of aluminum alloys, pre-hardened steels, and even composite materials. This material optimization focused on plastic material, often enhanced by electrical discharge machining, will lead to slower cutting time, less expensive aluminum molds and sufficient durability to be used as intended.

The consideration of quality differs depending on the applications required and both methods can be used to make high- quality parts so long as they are well designed and implemented. The decision to go with either the traditional and rapid tooling or standard injection molding is usually influenced by the quantity of production required, time lines, cost restrictions and the purpose on which the finished mold cavities an components will be used.

Essential Materials for Rapid Injection Mold Tooling

The choice of materials associated with rapid injection mold tooling is of critical importance, according to which the aluminum alloys occupy the first place, as they are highly machinable; possess best thermal conductivity; and offer adequate durability, which makes them suitable both to build and operate and achieve decent production volumes. Common aluminum types are 7075-T6 which is a high strength alloy and more generically applicable 6061-T6 aluminum which has good machining properties that are superior to steel, even when enhanced with carbon fibers .

And Pre-hardened steel offers great compromise in machinability and tool life, where it does not require so-called post-machining heat treatment and, in addition, has a better durability than aluminum. P20 steel is widely used in rapid tooling and gives satisfactory wear resistance and thermal resistance dimensional stability during the life time of the tool, making it suitable for full scale production .

Metal matrix composites and advanced composite materials, however, are become potentially effective in special applications, providing unusual combinations of new properties, including low thermal expansion and high thermal and exceptional wear resistance. Such materials, including rim molds, are generally high priced but can hold better results in difficult applications.

Copper alloys have special purposes in rapid tooling where specific applications may have unusually high thermal conductivity requirements or special electrical requirements. Copper alloys are not widely used in manufacturing, but they can still bring on a different set of benefits in a specific machining situation.

Step-by-Step Rapid Injection Molding Process

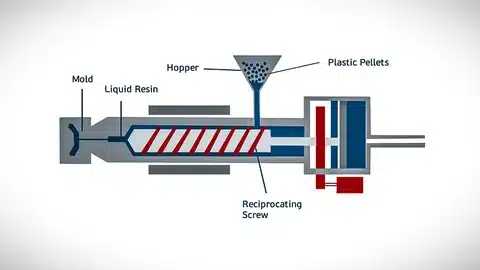

The Rapid injection molding process starts with thorough design analysis and optimization by the introduction of modern CAD system and analysis of the moldflow with intent to discover the problems that may occur in injection molding process and also to optimize the parts and tools geometry. This up-front investment in the product development process and rapid injection design validation can go a long way in eliminating the chances of issues on the production end and can also provide first-time success.

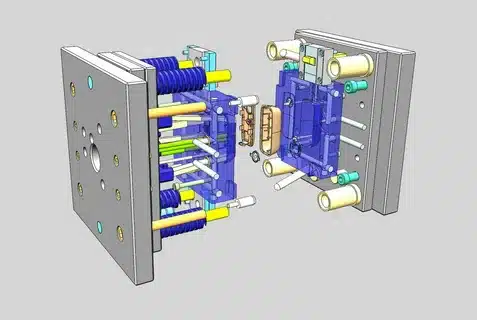

Tool design and engineering adhere to conventional injection molding guidelines with the addition of rapid tooling concept so that simpler cooling mechanisms, modular design and better machining practices can be adopted. Design time Assuming the design is already complete, usually the design stage does not involve extreme detail but helps to fulfill the necessary quality of the part at hand but with minimal complexity of tools and manufacturing time.

At this stage of manufacturing, high-speed CNC cutting, advanced tooling and cutting parameter optimization is used to ensure the minimum of cycle time and quality. Lights-out machining centers utilising automatic tool changers, high pressure coolants, and high level CAM software are capable of vastly decreased machining lead times.

Testing and assembly are made to ascertain that the tools operate well prior to production, and the initial sampling offers the chance to adjust the process parameters and establish that the parts measure up. This stage is usually accompanied by mold trials, process fine tuning and quality assurance to ensure the tool produces the same parts continuously during its active life.

Design Considerations for Optimal Results

The effective rapid injection mold tooling is given due consideration when the design guidelines are focused on a balance between functionality and cost of producing parts. The optimization of wall thickness will guarantee adequate material flow as well as low cycle time, low material consumption; the uniformity of wall thickness is especially vital to prevent warpage and sink marks.

Draft angles and undercuts should also be well planned so as to make sure that there will be an ejection of parts without making tools very complex. Although rapid tooling may be capable of cutting complex shapes, when a complex shape is avoidable, simplifying the design can dramatically cut the tool costs, as well as the manufacturing time and greatly enhance the quality and repeatability of the finished part.

Where parting line location influences the outlook of the part as well as the complexity of the tool, carefully chosen parting lines will help limit the amount of flash and the secondary steps required to complete the part. The section line ought to be positioned in such a way that it reduces the complexity of the tools and at the same time provides part support in the molding processes sufficiently.

The layout and positioning of gates set out patterns in which the material passes, quality and time cycles. The correct design of gate will fill the cavity completely and produce minimum gate marks and secondary processing requirement. When placing gates in an injection molding machine , characteristics of material flows, geometry of parts, and aesthetics should be taken into account.

Applications and Industries Leveraging Rapid Tooling

Rapid injection mold tooling is heavily used in the automotive industry to validate prototypes, injection molding services low volumes pieces of production, and custom pieces. Use Jim Mulligan has involved applications in the area of interior trim pieces, functional prototypes, and applications in more specialized pieces for race and limited production pieces.

Rapid tooling assists consumer electronics manufactures to develop consumer products, test in the market and produce accessories and specialized parts. Rapid iteration of designs and creation of working prototypes is a valuable asset in an industry where the technology evolves rapidly and product lifecycling are short lived.

The medical device manufacturers find rapid tooling in developing prototypes, the clinical trial parts and special devices that demand speedy market introduction. The strict nature of the medical industry as far as quality is concerned can be favorable with rapid tooling capabilities when it is appropriately implemented and validated.

Prototype components, tooling aids, and specialty parts Suitable to Aerospace applications are involved in research and development programs. Although most parts of the production aerospace may need conventional tooling because of the strenuous requirements of the regulations, the rapid tooling has significant roles during development and testing stages.

Cost Analysis: Investment vs Returns

The preliminary expenditure in rapid injection mold tooling is approximately 30-70 % of the customary steel tooling expense, depending on the complexity of the part, material picked, and quality needs. This lower cost of entry allows rapid injection molding quick tooling to be affordable to smaller production quantities and allows the company to test designs without investing in high cost production tooling.

Per-part costs are also dependent on the quantity of parts to be manufactured, the material being used and the cycle times but generally when production quantities are less than 10,000 parts the likely advantage of rapid tooling often has a cost benefit. Whether one will make the transition at break-even between the rapid and the traditional tooling will vary depending on the requirements of the application to be put as well as the production quantities that one works with.

The competitive advantages of time-to-market may offer meaningful competitive advantages so that rapid-tooling investments generate as much value as they cost in cases where unit-part expendable assumptions even rise beyond those available with traditional molding. Return on the ability to take a market share, evaluate designs early, and meet rapidly with client demands often brings a much higher return than direct manufacturing cost savings.

Considerations that form part of the total cost of ownership are the tool life, tool maintenance, and production abilities throughout the life span of the tool. Although the life of rapid tools can be shorter than that of steel tools, their significant cost benefits in useful applications can be in terms of low initial costs or quick replacement cycles.

Quality Control and Testing Standards

Quality control on rapid injection mold tooling entails rigorous testing standards which not only certify the performance of the tool as well as the quality of the piece during the manufacturing run. Primary parts sampling are supposed to incorporate dimension check, material test and functional check so as to ascertain that the cylinders will perform to shape.

The statistical process control techniques also permit steady part quality during production, ensuring frequent sampling and gauge can detect problems early on. The control charts and capability studies are quantitative overviews of process stability and how stable the quality of parts is.

Validation of material properties will guarantee that the mechanical, thermal, and chemical properties of the parts obtained by rapid tooling material and processes will be suitable. Such validation is especially valuable when the goal of rapid tooling is bridging to production tooling, i.e. the parts need to satisfy exactly the same specifications no matter how they are made.

The foregoing requirements on documentation and traceability are industry-specific and application-specific, with medical and aerospace applications normally requiring comprehensive documentation (both material and process) and quality control procedures. Regulation compliance and useful information to perform troubleshooting and process improvement will be provided by proper documentation.

Advanced Technologies in Rapid Tooling

Such additive manufacturing technologies and engineering are being combined with rapid injection mold tooling and allow detailed cooling channels and conformal cooling geometries, rapid prototype tooling in very low volume applications and allow quick quick build up of mold inserts and components for rapid injection molding work to reduce lead time and allow geometries not possible with traditional machining.

Designs of tools and plastic injection molding project processes can be virtually validated by simulation and modeling software prior to the physical construction of the tooling. To optimize a design and foresee any possible troubles, there is moldflow analysis, thermal modeling, and stress analysis, which saves a designer doing real-life iterations and fixes.

Multitechnology; Multitechnology manufacturing technologies are hybrid manufacturing technologies where several technologies are brought together to maximize tooling performance and to minimize time spent during manufacturing. More are examples of advanced additive manufacturing where complex internal geometries are combined with conventional machining of critical surfaces or insert molding type processes that mix materials in single tools.

Common Challenges and Solutions

One of the majorly significant issues in rapid injection mold tooling is tool wear especially in materials that are softer such as alloys of aluminium. Proper materials selection, process parameter optimization, and a form of preventive maintenance programs suitable to maximize tool life but retain part quality are ways to solve the problem.

Part encapsulation as a drawback in terms of finishing The surface finishing method may impair the look and performance of the part especially in cosmetic cases. Surface finishes can be as good as steel tooling through advanced machining processes using new types of materials and tooling and using post processing methods.

The issue of thermal management will also be raised in the context of rapid tooling applications because of the thermal characteristics of the commonly used tooling materials. Rational cooling system design, temperature control strategies and optimization of the cycle time are the techniques to keep the part quality with good precision and avoid thermal stress as a source of damage to the tools.

When materials are combining rapid tooling materials with definite kind of plastic resins or processing conditions, material compatibility problems can develop. Being able to further test thoroughly our materials, treating the material surfaces correctly and refining the selection of materials all add up to this compatibility being achieved, avoiding premature failures of the tools.

Future Trends and Innovations

The integration of the digital manufacturing is set to transform rapid injection mold tooling by enhancing the process to deliver advanced design to manufacturing processes, real-time process monitoring, and predictive maintenance. Principles of industry 4.0 such as IoT sensor, machine learning software, or cloud-based manufacturing systems will increase efficiency, and reliability in rapid tooling.

The rapid tooling materials and processes innovation is because of sustainable manufacturing practice, in which more attention was paid to recyclable tooling materials and energy-efficient manufacturing processes and fewer wastes were produced. Issues on the environment and sustainable practices re also gaining prominence in terms of material selection or the optimization of the tooling process.

The capabilities of rapid tooling are further increasing with advanced material development providing new alloys, composites and surface finish applications and corresponding increased performance characteristics. Nano-structured materials and high-performance coatings offer the potential of supplying longer tool life, high part quality, and supporting high volume production while preserving the speed benefits of rapid tooling.

Adoption of automation and robotics will further extend the time of lead and profits in consistency of rapid tooling manufacturing. With automated setup, lights-out machining solutions and robot finishing, turnaround time will be further accelerated and labor costs will be lower and consistent quality achieved.

Selecting the Right Rapid Tooling Partner

When choosing partners to work with, it is important to evaluate them on basis of their technical skills, quality systems and experience in rapid tooling applications. Machining, material knowledge, quality management systems and capability to achieve challenging turnaround times without compromising quality in an injection molding machine are some of the key evaluation criteria.

The ability to communicate and work, together, plays an important role in effective rapid tooling initiatives where effective communication channels, frequent status reporting, and joint problem solving regimes are factors towards project success. The partners ought to be ready to work intimately with customers in the development process.

The quality certifications and compliance to industry standards are signs of commitment to quality and process control by a partner. Standards like the ISO 9001, AS9100 or ISO 13485 indicate compliance to documentation practices in quality management and compliance to the regulators.

The specifications like geography, the ability to ship and the compatibility between the time zones such as the ability to communicate in a timely manner, could play an important role in executing a project plan and making the contact an effective one. Local partners can be useful in communication and logistics, and international partners could allow a cost benefit or new subsets of capabilities.

Best Practices for Implementation

Before starting thinking about rapid tooling projects there should be some objectives, there should be a schedule determined and project should have some success parameters that should be put forward. Thorough planning such as design reviews, choice of materials used and process confirmation ensures that it leads to success and avoids delays of modifications which are very expensive.

The design to create rapid tooling will have to be optimized based on the identification of the peculiarities of rapid tooling processes and their opportunities. Design and manufacturing teams should collaborate early enough to help establish optimization opportunities which would enhance part qualities and effective design manufacturing.

Process validation guarantees assuring correctness and general condition of parts and tool performance over manufacture lines. Validation procedures are to involve an initial sampling, shaping up of processes and continuous observation to ensure the quality standards and to spot opportunities of improvement.

The constant upgrade schemes are used to enhance rapid tooling processes and results in the long run. The frequent auditing of projects, lesson learned reporting and process improvement help in enhanced abilities and customer performance.

Integration with Global Supply Chains

The concept of the supply chain also becomes more relevant with the faster product development cycle and global entry at the hand of rapid tooling. Interoperability with logistical partners, customs clearance processes and global shipment needs makes it easy to move an item that has been made using rapid prototyping needs to global branding.

The universal quality in the process of manufacturing across the manufacturing global networks demands standard processes, materials and the control of quality. Rapid tooling may take the role of a bridge technology by allowing local manufacturing needs and ensuring global performance and quality standards and easy logistics.

Shenzhen Guanwutong International Freight Forwarding Co. Ltd. (GWT Worldwide) is the kind of logistics partner that would be needed in achieving success in rapid tooling in the international markets. GWT Worldwide, being a professional logistics service provider with focus on global freight forwarding, supply chain solutions, and cross-border e-commerce logistics, provides all the comprehensive services required to support rapid tooling projects. The main services such as air freights, ocean freights, China-Europe railway freight transportation, worldwide express solutions overseas, custom clearance, and warehousing plus Amazon FBA shipping offer the logistics backbone that is required in the case of successful rapid tools projects. Companies such as GWT Worldwide are doing this by incorporating top-notch technology in the logistics system alongside a world-wide system of trusted customers to make sure that their goods arrive within factories in a secure and timely manner and in a manner that adheres to rules and regulations.

Contingency planning and supplier diversification and quality assurance initiatives that can be consistent across geographically dispersed manufacturing sites and logistics providers are needed in risk management in global supply chains. The flexibility of rapid tooling allows the responsive supply chain strategy which is capable of responding to changing markets and logistic problems.

Environmental and Sustainability Considerations

Energy consumption, waste management and disposal as well as material selection Environmental impact assessment of the rapid tooling processes should be given to the way of choosing the material involved, energy consumption, waste production and disposal options available when the life of the tooling process will end. Rapid tooling can have sustainable practices, which fulfilled the general corporate aim of environmental protection as much as sustained manufacturing tools.

Environmental factors such as recycling, energy used to produce and effects on the environment during disposal is becoming a major consideration when choosing the material. Aluminum alloys are very recyclable and the steel tooling gives high durability that can save environment in long term since long life of tooling can be maintained.

Energy efficiency optimization in rapid tooling production involves use of high-efficiency machining principles, cutting parameter optimization and use of renewable energy where feasible. New manufacturing outfits also introduce energy efficient cutting edge technology which is less environmental friendly but fully productive.

Waste reduction practices are aimed at to use of materials economically, recycling of cuting fluids and chips and waste by packaging. In rapid tooling, the operation can be run on the principles of circular economy in order to reduce environmental impact with economic sustainability.

Regulatory Compliance and Standards

Rapid tooling medical devices, aerospace industry rapid tooling, including automotive, among regulated industries are influenced by industry-specific regulators. Knowledge and adherence on appropriate regulations makes it acceptable in the market and prevents unnecessary redesigns or hold ups caused by regulations.

ISO 9001, ISO 13485, and AS9100 quality standards are guidelines that facilitate quality management in operations of the rapid tooling. These standards assist in maintaining the quality and continuous improvement and prove commitment towards customer satisfaction and regulation.

The extent of documentation needed in relation to industry and application differs, where some applications such as the food industry require a lot of traceability and validation documentation. Documentation systems that are well documented guarantee compliance and also give effective data to troubleshooting or improvement of processes.

Testing and validation procedures have to be in accordance with the requirements of the industry and customers so that the part can be accepted and the manufacturers can comply with the regulations. Detailed testing schemes allow to be sure in the quality of parts alongside to demonstrate diligence in terms of quality control.

Заключение

Rapid injection mold tooling has now become a breakthrough technology, which is helping various industries in developing their products quickly and at low costs in addition to bringing more responsiveness into the market. The maturity in the technology has led to one of its reliable processes, which will result in quality parts that can be used in reproduction and in the prototype of a product. In rapid tooling success, design optimization as well as the selection of materials, control over the manufacturing industry process and the selection of partners should be considered vigilantly in order to deliver the best results.