Meta Description: Learn everything you need to know about cnc hold workholding methods for stock a CNC router and create our 14- method guide to workholding e.g- T-tracks, vacuum table, and others. Acquire professional skills of safe accurate machining.

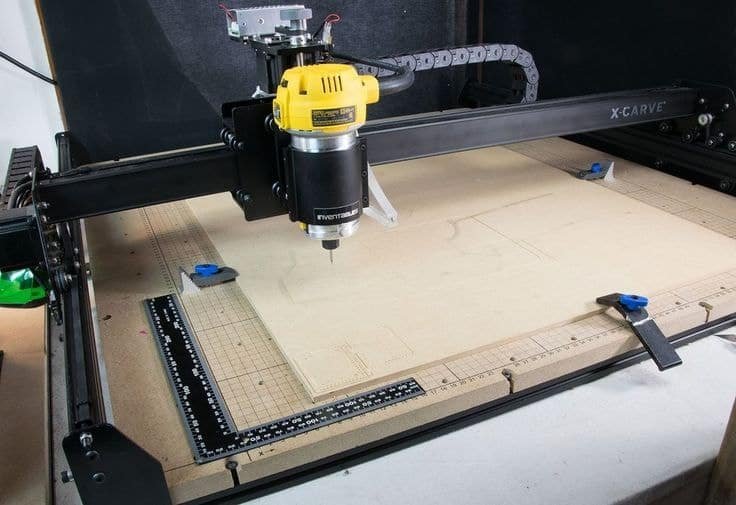

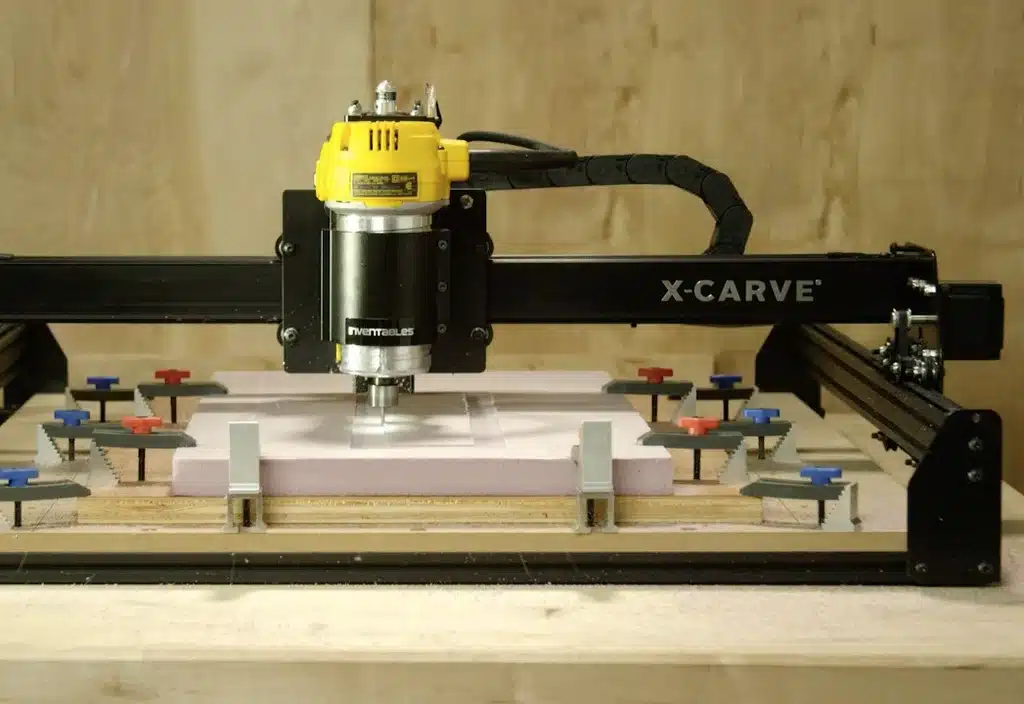

Introduction to CNC Router Workholding

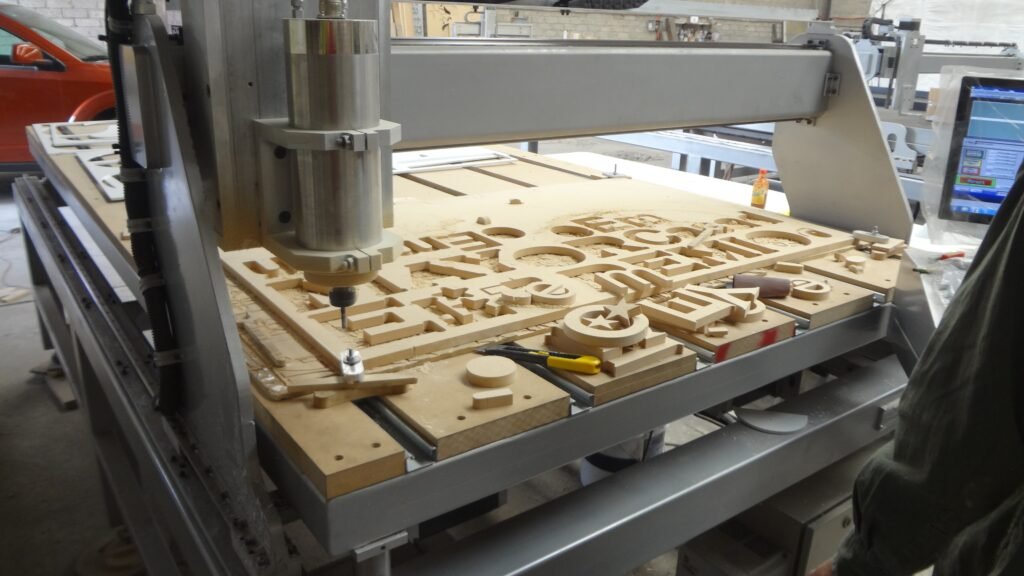

Workholding in CNC router is what makes the difference between the success and failures of cnc hold machining jobs which form accurate parts and expensive errors. The way you hold work is the way in which you keep a wood material in place during cutting in a CNC machine, and the way in which you decide to do that can lead to a rich discussion about your project result. In workholding, being conversant with the different methods and procedures enables the workshop person (whether the hobbyist or the professional machinist) to hold on to their materials in a way that they remain safe in the cutting process while retaining their dimensions.

Work holding in CNC operations is very crucial. Bad workholding causes part movement, tool failure, inaccuracy of dimensions and even safety risks. Contemporary HSC routers have very high cutting speeds with large cutting forces, including plywood so a secure grip and material clamping is important not only to quality, but also to safety.

Understanding Workholding Fundamentals

Proper workholding systems, including hold downs, should achieve a number of important goals at once. They should be able to give adequate clamping force to oppose cutting forces in every direction, offer accurate part positioning throughout the machining cycle, offer the required tool clearance in cases of complex geometries and the required change of setup in minimal time to make the production run effectively.

The workholding setup is the key element to your CNC machining process! Your work holding methods are CNC and can utilize a vacuum table to hold your part in an unyielding position and due to that the stiffness is lessened. There is a direct correlation between the work holding rigidity and the quality of the surface finish, where a secure hold prevents poor clamping that leads to twist, vibration and chatter marks, and unreproducible dimensions.

Mechanical Fastening Methods

Simple workholding methods can be achieved by direct mechanical fastening of many CNC router applications. The easiest example of work holding is to simply use some drywall screws on mdf , but in this case, one will need to consider all the places where they can put the screw to make sure not to collide with any tool.

Use of low profile screw in spoil board waste spots on your working piece should be considered during application to experiment with mechanical fastening. Implanting the screws beneath the surface of the material helps avoid the contact of the tools without loosening the clamping adequacy. In the case of hold downs and through-hole, screw placements can be done strategically somewhere not in the path of machining so that it can be continuous without repositioning.

T-Track Systems and Their Applications

The T-track systems lead to outstanding flexibility in the CNC router workholding and the adjustable clamping positions along with the standardized mountings. Such systems emulate modular work holding based on aluminum with T shaped slots that have special bolts, clamps, and double sided tape delivered onto the aluminum profile system.

Repeatability and the flexibility offered on T-track systems makes them preferable among the professional CNC operators. Fixed sizes provide the ability to follow the same creation steps and the modularity supports different size parts without customizing the tools. T-track systems allow fast part change over at the edge in a woodworking production setting when used in conjunction with stop blocks, positioning pins, and double sided tape.

Threaded Insert Installation and Usage

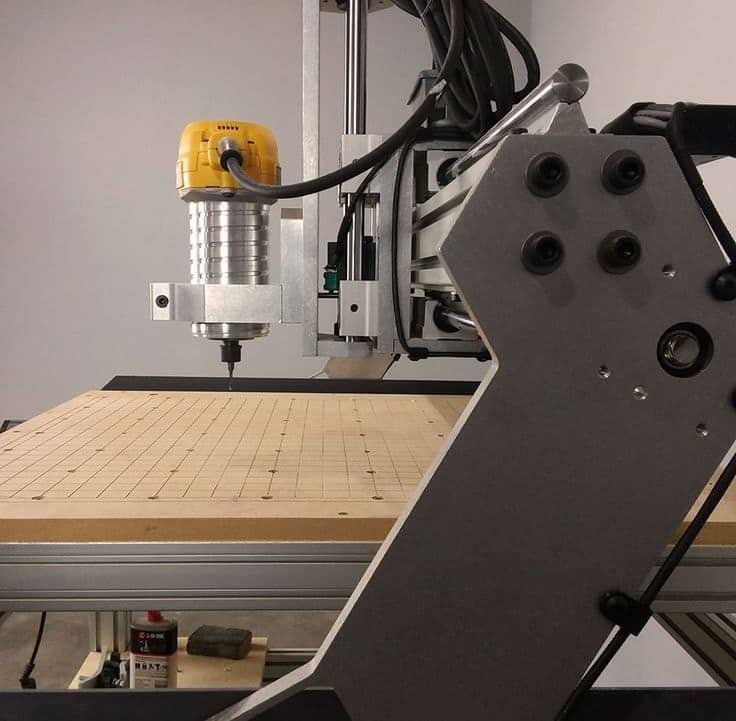

Use of threaded inserts on average spoilboards changes it into corner-to-corner workholding surfaces offering secure mounting points around the machine bed and working area. These are metal inserts that are normally of steel or brass and they are threaded into pre drilled holes, ensuring that regular bolts cannot be too loose when clamped.

The holes have to be adequately sized and the depth controlled to allow the insert to be engaged to the correct level. The vast majority of CNC routers should be able to make the necessary holes automatically giving the standard grid patterns produced that help make it as flexible as possible. Threaded inserts only require installation and deliver hundreds of clamping cycles without any loss of thread.

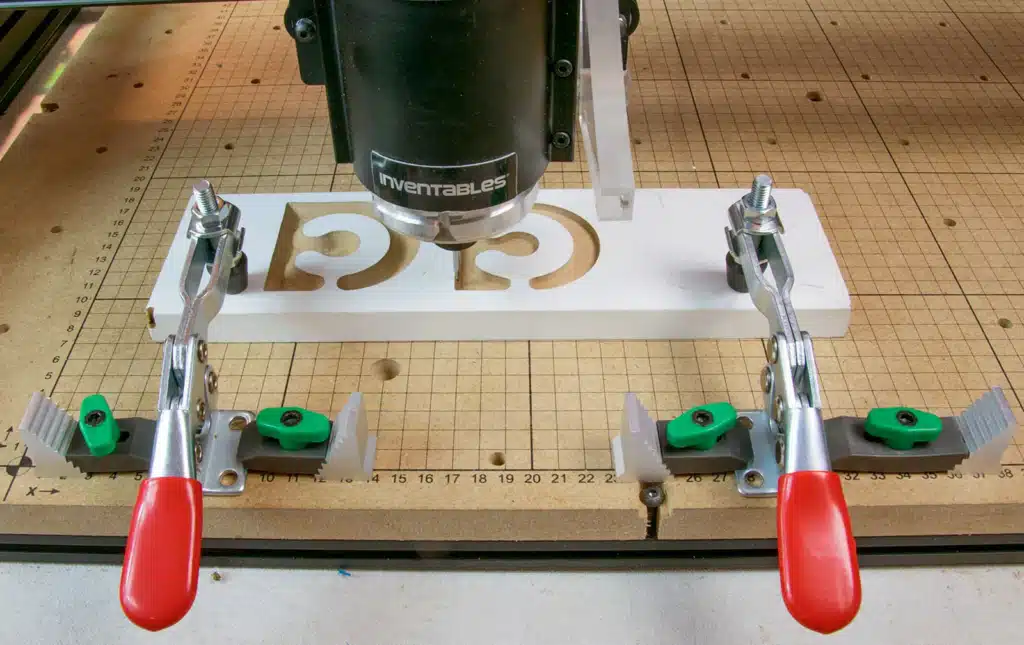

Clamp-Based Workholding Solutions

The old-fashioned clamping is still a representation of one of the steadfast forms of workholding CNC routers especially when a person is faced with unusual shaped workpieces or material that cannot be altered using fasteners. This is achieved through the use of screws or clamps or any other fastener, a good friend in the workshop, but each method carries certain benefits.

The clamps used in modern CNC have low profile design with little intrusion into cutting tools yet they deliver high clamping force. Each of the following clamps has its use, such as toe clamps, step clamps, and edge clamps, and correct knowledge of using all the above, including a new one one is also assured of the best out there. The success of clamping is to ensure that clamps are placed in a certain position so that they can oppose the main force of cutting without causing interference with the tool path.

Adhesive Workholding Techniques

Adhesive work holding techniques have become highly used because they are simple and very efficient especially when dealing with smaller work pieces or work parts that cannot be held using mechanical fasteners. However, one of the most common ways to do it is to apply painter tapes and super glue, which is quite remarkable in holding power when used correctly.

A workpiece/ sacrificial layer/ spoilboard applies the tape-and-glue technique, which, via the little effort to remove the part without destroying either the workpiece or the spoilboard. Surface preparation should be conducted properly by washing the two surfaces using the right solvents and also the full contact between the two layers of the tapes should be applied. The approach is highly valued with minor materials, or finished surfaces unable to support a mechanical fastener.

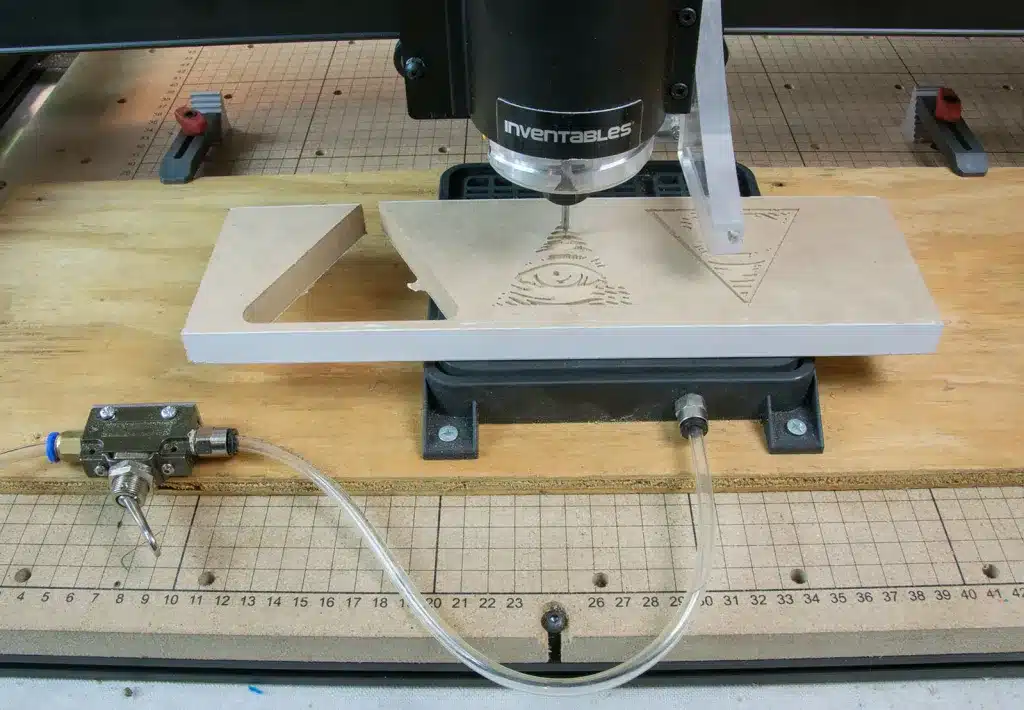

Vacuum Workholding Systems

The highest form of the CNC router workholding technology is the vacuum workholding which exerts equal clamping force on the entire area of the workpiece without any mechanical assistance. Vacuum pump systems establish a surprising negative pressure below porous spoilboards such as baltic birch plywood, thus literally sucking the workpieces against the table.

Professional vacuuming also includes zone control, which enables the selective use of vacuuming on table sections. This is extremely useful when machining more than one part during the same time or involving a part, which has different thickness. This distribution of uniform pressure also minimises distortion to the workpiece as it would be the case with point-loading clamps.

Fixture Design Principles

Custom fixtures also go beyond workholding basics to include part positioning, tool guidance and repeatability of the process. Tooling Plates usually employ a pattern of holes which alternate the precision dowel points to position and the threaded mounting holes to secure, which makes up a system of references in complex assemblies.

Good design of a fixture deals with what is accessible, extreme stiffness and cost of manufacture. You usually get better performance with simple fixtures than complex designs because the amount of time to set up and possibilities to make a mistake have been minimized. The ideal fixtures are those that use flawless part loading, unobstructed access to the tool and reviewed construction that can take the punishment of regular use.

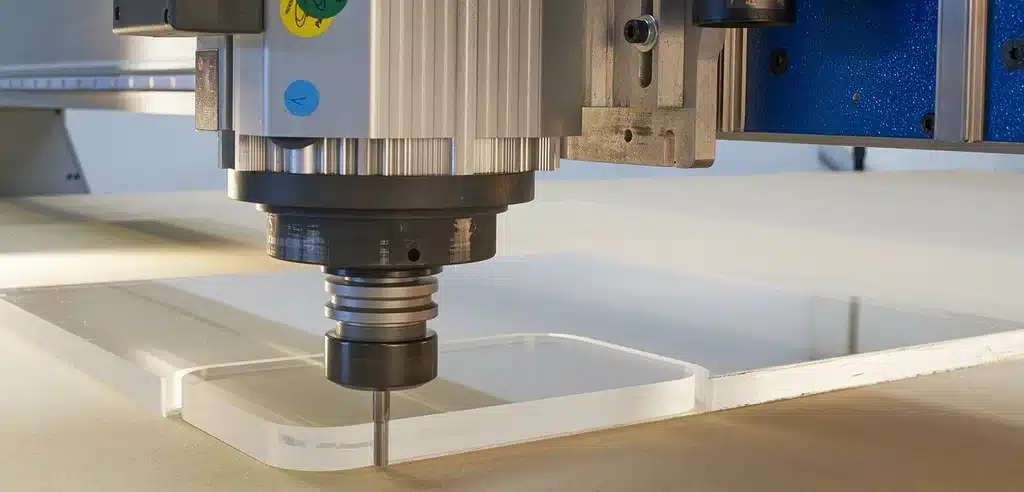

Vise Applications in CNC Routing

Although a vises are traditionally related to milling processes, they are specially used in CNC routing of smaller workpieces which require proper alignment. The issue with CNC router implementation is the fact that due to clearance that the gantry needs, the vise must be low profile in order to accommodate this clearance for various projects so the correct vise selection is pivotal in successful implementation.

CNC router vises need to strike a balance between necessary clamping power and clearances (which may require special low-profile designs). These vises work best in machining of a number of small components or where precise angular orientations are necessary. Firm clamping nature of the good vises can sometimes be worth using even when its clearance is constrained.

Hot Glue and Temporary Fastening

Hot glue workholding is a fast, reversible technique of holding light workpieces during CNC work. Such a method involving masking tape s especially successful with prototype work, short runs, or work requiring the use of a material which will not accept other fastening systems.

Effective working of hot glue workholding and double faced tape is attributed to the head of appropriate control of temperature and technique of application. Excessive heat may destroy thermoplastic materials whereas low amount of heat leads to lack of adhesion. Hot glue can be removed easily and hence it is suitable to work on those parts where no finishing operations on any surface is desired.

Safety Considerations in Workholding

Workholding safety does not only refer to part security but also operator protection and equipment safety. Insufficiently fastened workpieces may turn into a deadly projectile, and poor clamping may lead to damaging occurrences, happening to costly cutting tool and machine parts.

Frequent checkups of the workholding hardware helps to avoid disastrous breakdowns during the operation. Moldy clamps, broken threads, and corroded adhesives are the similar contributors to the combination loss of workholding integrity. Development of inspection practices and schedule of replacement ensures uniformity of safety practices in the production processes.

Material-Specific Workholding Strategies

There are machining materials, especially wood that require a certain individual workholding technique due to the nature and physical attributes of the stock material. Fine materials such as foam and plastics have lesser clamping forces needed to make them avoid deformation, solid materials such as metals need powerful systems to withstand cutting forces applied.

The characteristic challenges in wood workpieces are in grain direction and differences caused by moisture content. Cross-grain clamping may split workpieces, and seasonal movement may act on dimensional stability. By knowing these material behaviors, the right selection of work holding and wedge is possible and failure is avoided leading to wastage of money.

Troubleshooting Common Workholding Issues

Other typical workholding issues are part movement, vibration, tool interferences, and non-efficient setup time. Slippage at the part is a usual symptom of inadequate clamping pressure or incorrect force direction whereas resonance between the part and the clamping system starts vibration.

Force analysis is the start of systematic troubleshooting, which is involved in knowing about cutting loads and directions. Most common issues are avoided by matching workholding capacity with such forces. In cases where there are problems recurring it is usually found that the matter set up processes are either wrong or not followed through without tolerances being compromised which in turn will affect the workholding performance.

Заключение

The secrets of CNC router workholding are good to know in the community the principles of every technique and choose the methods that should be used in particular situations. Whether simple mechanical fastening or complex form of vacuum system, each one has its own specific benefits to enjoy in case of correct implementation. The trick is in aligning workholding techniques to part demands at the same time not compromising standards of safety and efficiency.

The performance of results is entirely professional with consistent implementation of best-known workholding principles. As you are gluing fragile veneers, using sticky solutions, as well as clamping heavy steel plates by abrasive ways of doing things with a good bit , the rule is that technique is everything in securing consistency and good results. The payback on investing in amazing quality workholding systems is virtually realized in better quality parts, shorter setup times, and an increase in safety in operation.