Detecting metal in archaeological records enables study of human technological development where early copper discoveries alongside bronze belong among the most critical metallurgical breakthroughs, particularly in applications related to marine equipment . Through these metals humanankind moved beyond stone tools leading to significant changes in the direction of civilization. The heritage links between bronze and copper steel exist because bronze uses copper as its base metal, which provides high corrosion resistance, but their material properties create diverse uses during human history until the present day.

The Dawn of Metallurgy

According to archaeological records human exploitation of copper began around 9000 BCE which establishes it as one of the earliest metals used by prehistoric civilizations, often with varying zinc content . The unprocessed state of copper made it possible to work with through simple hammering before requiring advanced smelting methods. Copper established itself as the first metal widely adopted by humans because of its thermal and electrical conductivity, as it was accessible for turning into tools and decorative objects which spread across the early settlements of the Middle East and Eastern Europe.

The Bronze Age Revolution

During 3500 BCE ancient makers achieved an important breakthrough when they learned that tin bronze was formed by uniting copper with tin, which led to a tougher and more adaptable metal substance known as a metal alloy . The discovery of uniting copper with tin led historians to name this period the Bronze Age which brought enormous technological development. When early humans switched from copper to bronze it led to one of the most important technological transformations in human history since this created stronger tools that revolutionized the practice of farming and combat as well as artistic work.

Copper: The Elementary Metal

The periodic table identifies copper as element number 29 and gives it the abbreviation Cu which comes from Latin cuprum. Today most extracted copper, known for its high conductivity, originates from minerals whereas pure native copper appears sporadically in nature but modern extraction occurs from minerals such as chalcopyrite and both malachite and bornite. The reddish-orange nature of this metal along with its outstanding physical characteristics has motivated its essential usage since prehistoric times.

Bronze(aluminum bronze): The Transformative Alloy

Modern bronzes include common bronze alloys such as aluminum bronze, copper and tin combinations containing about 12% tin content but also add different elements such as aluminum manganese nickel or zinc in particular ratios. Copper loses its original properties when alloyed with other elements and attains new character traits such as increased hardness along with better casting capabilities and better protection against wear and corrosion. The development of bronze stands as one of humanity’s first deliberate material science innovations.

Metallurgical Properties of Copper

Attributes of exceptional nature in copper brass have allowed it to maintain its perpetual use patterns. The excellence of copper’s electrical properties comes second only to silver within the metallic elements making it vital for electrical usage due to its excellent electrical conductivity . Being high in thermal conductivity copper provides excellent malleability along with ductility features and naturally resists diverse types of corrosion. Material workability remains possible for copper due to its 1,085°C (1,985°F) melting point even though it easily shows its distinct color for visual recognition.

Metallurgical Properties of Bronze

The combination of materials in bronze creates material attributes that outperform copper in all aspects. Tin addition to copper creates stronger and harder materials that can be easily castable at about 950°C (1,742°F). The material properties of bronze include improved resistance against metal fatigue and better wear attributes as well as good corrosion resistance and improved corrosion protection especially in sea environments. People have used metallic bronze often because of its attractive golden-brown hue and outstanding ability to achieve high reflective finishes for decorative purposes.

Early Applications of Copper

Archaeological evidence demonstrates that during the prehistoric period people used copper mainly for decoration and worship through artifacts that were fashioned between 11,000 and 10,000 years ago. Different metallurgical methods allowed copper to start being used for basic tools together with cooking pots and water carriers as well as agricultural instruments. During the earliest historical periods Mesopotamians together with Egyptians and Indus Valley residents incorporated copper into their religious art and built architecture and basic plumbing solutions. The material held exceptional value for creating shaped tools through hammering because it could be easily shaped by hand.

Bronze and the Rise of Complex Civilization

Society experienced extensive societal transformations as a result of bronze technology’s introduction. The combination of bronze tools and weapons which surpassed copper tools enhanced agricultural productivity to a notable degree. Military superiority stemmed from bronze weaponry which simultaneously enabled builders to construct advanced structures because of its tool durability. Dense civilizations started forming because of bronze production since bronze required dedicated tradespeople and specialized network systems to operate the entire cycle of production. Bronze possessive civilizations exhibited clear superiority against other societies which did not have access to this technological metal.

Copper in Ancient Warfare and Tools

Despite surpassment by bronze for most uses copper continued serving military purposes along with toolmaking in ancient times. The archaeological record shows that copper maces and arrowheads along with axes continue to appear alongside copper tools despite the arrival of bronze weaponry. Numerous societies preserved copper and zinc applications for particular purposes that required its favorable properties along with its cost-effective nature. Through unknown mechanisms in ancient times the antimicrobial nature of metal helped sustain its usage in preparing food and storing water despite its scientific understanding being discovered just recently.

Bronze: The First Military-Industrial Metal

Entire ancient warfare systems changed due to bronze weapons which incorporated advanced swords, spear points, armor, shields, and helmets. The battlefields that used to be controlled by stone and red metals like copper weapons now experienced decisive advantages through these newly invented implements. Bronze weapons became durable and deadly because of the material’s tensile strength, hardness, and sharp edge maintenance properties and bronze armor provided improved defensive capabilities. Kingdoms entered strategic metals control competitions for both necessary resources and technical expertise which occasionally determined political and military dominance.

The Copper Trade Networks (copper alloy)

The widespread distribution of copper across ancient territories required substantial trade networks because its distribution was not even throughout the world. Standards show that miners transported copper over distances exceeding hundreds of miles to reach manufacturing factories aluminum bronze. Copper trade elevated the point of contact between faraway cultures through intricate trade networks that left significant historical traces from Europe to Asia and Africa. Trade networks acted as conduits for material distribution as well as technological advancement because metallurgical information traveled between the trading points.

Bronze and Ancient Technological Innovation

Merely weapons and bronze metal alloys were not the only technological achievements that bronze enabled. Bronze components enabled manufacturing of hinges, fasteners and gears and complex mechanisms which stone and copper materials had limited capabilities in producing. The superb casting abilities of bronze permitted makers to create precise machine components which had excellent lifespan even when subjected to substantial stresses. The properties of bronze enabled ancient society to construct advanced technological systems through multiple eras including astronomical devices together with irrigation systems.

Copper’s Electrical Revolution

The progression of human technology hit its most significant milestone in recent times because of electrical applications utilizing copper. After scientists Faraday, Ampère and Ohm made their findings, electrolytic copper emerged as the essential element required for developing electrical systems because of its remarkable conductivity and high corrosion resistance. Electricity distribution infrastructure emerged from copper material which brought about telegraph systems and lighting as well as motors and generators before powering modern electronics systems. Human progress owes its greatest advancement to this particular copper application.

Modern Copper corrosion resistance Applications

Today copper plays an essential role for a wide range of industries in modern applications. Electric wiring represents the biggest industry use of copper because buildings and motorized systems and diverse infrastructures rely on its conductors. Plumbing systems apply copper in their water distribution networks because the material demonstrates resistance to corrosion and antimicrobial behavior. The material stands crucial for sustainable energy technology since it powers solar systems, heat sinks, alongside wind turbines and energy storage technologies. Democratic industries like telecoms and construction and transport beside electronics maintain their operations through copper’s distinctive attribute set.Electronics, telecommunications, transportation, and construction continue relying heavily on copper’s unique combination of properties.

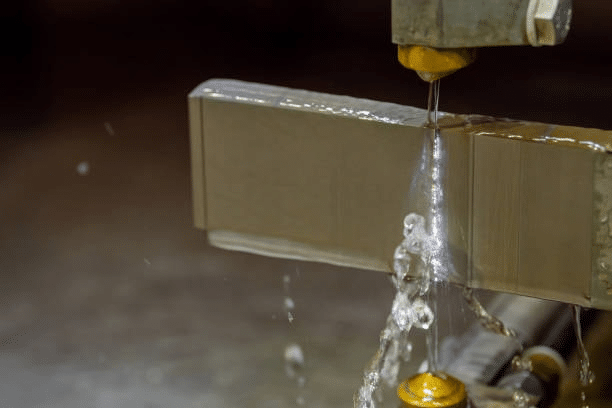

Contemporary Bronze Utilization

Although bronze handed its dominant position to other metals it retains specific utilizations that rely on its unique properties. Marine hardware depends on bronze since it demonstrates better performance against seawater corrosion. Due to its low friction behavior the alloy shows top performance in bearings and bushings applications. Bronze IT maintains its traditional association with musical instruments along with bells due to its advantageous acoustic properties. Today, bronze is used regularly to produce sculptures together with decorative architectural components as well as commemorative items because it combines appealing aesthetics with excellent casting potential.

Comparative Physical Advantages

The selected applications for copper and bronze materials are primarily determined by their physical characteristics during evaluation. The electrical conductivity of oxygen free copper versus brass vs bronze exceeds bronze by about 65% hence making it indispensable for all electrical systems. Thermal conductivity overlaps with copper’s superiority thus making it prevalent in heat exchangers alongside cooling systems. Bronze, however, offers substantially greater hardness (typically 3-4 times harder than copper), superior wear resistance, and better performance under load-bearing conditions, particularly where friction resistance matters.

Economic Considerations Between Metals

Movement of minerals and their price play a vital role in deciding between copper and bronze material selection. The price of pure copper stays beneath brass and bronze except when global markets influence them both. The two metals differ in their production techniques since bronze enables better casting of intricate shapes but copper works better for making formed parts. The long-term cost management of bronze solutions works best in demanding applications that need extended use and low maintenance yet copper possesses better end-of-life economic value through its higher scrap price. The excellent recycling capabilities of these metals improve their total economic advantages.

Environmental Impact and Sustainability

The environmental issues that arise from these metals show unique characteristics. The mining along with processing of copper needs big energy inputs while creating major adverse environmental effects through habitat destruction and dangerous water pollution potential. Quality control for bronze manufacturing requires evaluating mining operations of tin along with other existing industry challenges. The materials show outstanding lifespan capabilities and endless recyclability without quality loss which leads to superior environmental performance during their product lifetime compared to typical substitute materials. The adoption of circular economy principles reveals copper and bronze as sustainable materials in suitable structural conditions.

Architectural Applications: Copper vs. Bronze

Performance alongside visual appeal causes architecture to remain a field that favorably incorporates copper and bronze as key materials. Trace elements in copper-based materials create long-lasting survival which extends beyond 100 years and results in architect-favorable green patina formation. The weather-resistant bronze architectural details enhance buildings through their durable nature as well as their warm color transformation into dull gold or dark brown or almost black aged surfaces. The aging processes of both metals establish opportunities for architectural creativity which surpass most modern building products.

Artistic Expressions Through Copper and Bronze

Throughout history artists have used these two metals because of their separate characteristics. Malleable copper features in repoussé and chasing metalworking methods which help create elaborate relief sculptures and ductile copper allows skilled artists to produce detailed wirework art. Recent sculptors use ancient lost-wax casting technology from bronze ages in their work alongside this metal. Artists benefit from the two metals’ varying visual signatures because copper displays a warm reddish hue yet bronze appears as golden-brown and this enables artists to communicate multiple artistic goals through their work.

Corrosion Characteristics and Patination

Through time exposure the metals form protective layers which simultaneously produce unique visual outcomes. When exposed to atmospheric conditions copper develops a protective green patina primarily composed of copper carbonate which might need decades to form electrical and thermal conductivity

. The alloy composition of bronze and environmental conditions influence the development of dark brown through blackish patinas. According to corrosion standards, bronze is corrosion resistant, showing better resistance to damage in marine conditions thus it dominates nautical applications. Experts use chemical solutions to manage and speed up patination reactions of both metals depending on the desired visual appearance yellow brass.

Future Technological Applications

Modern technologies are developing new uses for these ancient metallic resources. Copper’s antimicrobial capabilities now receive increased scientific interest for medical uses because copper-alloy surfaces effectively eradicate bacteria and viruses and fungi. Due to excellent thermal properties, aluminum bronze alloys, and copper remain essential for cooling high-performance electronics because rising computing needs intensify copper brass and bronze. The manufacturing industry uses bronze for advanced bearings as well as wear-resistant components. The combination of both metals serves the field of additive manufacturing through 3D printing to deliver components with specific functional properties and processing parameters.

Global Production and Resource Considerations

The world produces more than 20 million metric tons of copper per year and Chile and Peru lead major copper-producing countries together with China and the United States. The statistical data for bronze production remains challenging to identify because the alloy finds uses in many different industrial entities. Material selection depends more heavily on resource constraints because copper encounters expanding market needs from developing countries along with renewable technology requirements alongside diminishing rock-grade contents brass bronze and copper. The reuse of these metals continues growing since it now provides roughly 35% of copper sector requirements.

Conclusion: The Enduring Legacy of Civilization’s Metals

Copper and bronze serve as the two principal metal artifacts which have strongly influenced human progress since ancient periods until our current age. These related materials differ by specific properties to suit different applications despite their common chemical makeup. Copper, known for its density copper, dominates our electrified world due to its unmatched electrical conductivity performance and bronze continues to be essential through its hard visage and resistant properties against wear and corrosion to specific applications. The development of human technology can be traced through metal evolution which started with hand-hammered tools and progressed to modern electronic parts and accurate engineered products.

Civilization approaches increasing sustainability problems while copper and bronze demonstrate important traits of long-lasting material components and recyclable systems. Sentimental components made of these metals survive many decades to centuries until remanufacturing occurs in which they maintain high-quality properties. Circularity together with longevity has emerged as essential material quality measures due to increasing emphasis on resource efficiency.

Through generations copper and bronze materials proved their exceptional nature by adapting into modern technologies while preserving their ancient significance. Such extended historical significance with bright future prospects only exists for a few materials.