Meta Description: Get the best injection mold design for manufacturing plastic parts and injection molded parts and learn all of the key time-tested rules, dos and donn as well as key strategies and tips of the experts that will help you achieve optimum manufacturing outcomes and cost-saving in 5000 words.

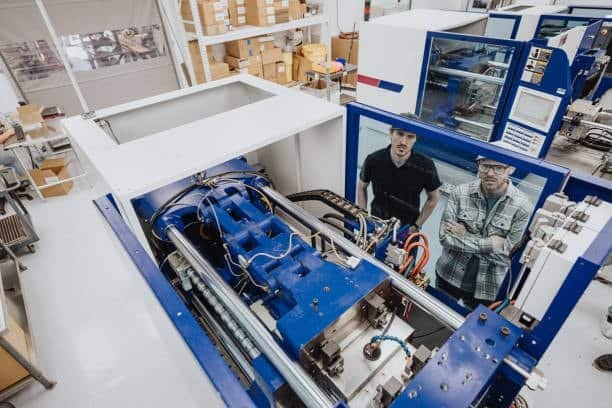

Introduction to Injection Mold Design Excellence

The injection mold designing can be attributed as one of the most imperative phases in the manufacturing process of injection molding contemporary manufacturing, which directly affect quality of products, efficiency of production and general affordability. The complex design of obtaining accurate molds imposes a profound knowledge on materials, geometry, flow mechanics, and production limitations. This in depth book covers the basic concepts and techniques that make up effective injection mold design.

Mold design is of utmost importance long after the period of manufacturing. Properly made molds maintain good part quality, decreases defects in the production process, optimizes increase in cycle time, and finally, it leads to a sustainable manufacturing structure. In consumer electronics, automotive plastic parts, medical devices, or any other application development of any product, it is necessary to observe the design principles stipulated, including ensuring proper wall thickness, to attain features of excellence in manufacturing.

Understanding Injection Molding Fundamentals

The injection technique is the method of process where the molten plastic under a great pressure and temperature is forced into a perfectly designed cavity. The process appears to be rather simple but demands analysis of a great number of variables such as material characteristics, mold shape, processing and cooling technologies. Knowledge of these principles would be used in the development of effective mold design that will serve technical specifications and commercial aspects.

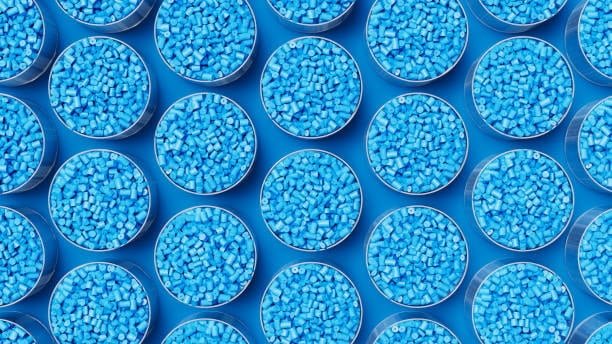

The choice of material is very crucial in the mold designing. Varying plastics have different flowing properties, shrinking properties and different thermal properties, which directly affect the mold designing parameters. Each of the thermoplastics such as ABS, polypropylene or nylon presents its own set of challenges and opportunities including thick sections that should be handled by careful guidance in the design.

Critical Design Considerations for Mold Success

Designing a successful injection mold with thin walls juggles numerous competing requirements, especially in thin wall injection molding without losing sight of how the resulting end product will be used and how it will look. Competence The needs of the modern products are complicated and may require new solutions stretching the limits of the classic technique of molding. The design engineers have to make sure that not only the current manufacturing needs are put into account but also the sustainability of long-term manufacturing and cost optimization are achieved.

One of the changes is the incorporation of higher-end simulation software which enables the designer to forecast and refine the performance of mold prior to the onset of physical production. With these tools and a molding machine , it is possible to analyze the specifics of material flow, cooling effectiveness and possible formation of defects in great detail, which allows a significant decrease in the development time and costs.

Ejector pins Material Selection and Properties

One of the most fundamental decisions in the design of an injection mold includes material selection. The selected material should meet the functions and but be compatible with the molding process and design parameters. Engineering plastics will have better mechanical properties but they need special processing conditions; commodity plastics are cost effective though their performance properties may be limited.

The nature of material flow is vital to know how to place the gate, what the runners should be like, and how the mold geometry as a whole should be. A high viscosity material needs to be designed in a different manner than a low-viscosity variant with implications to the choice of wall thickness, rib shape, plastic flow and cooling procedures.

Wall Thickness Optimization Strategies

Having a uniform wall thickness is one of the principles of the injection mold design that engineers strive to maintain uniform wall thickness, but it is often achieved with some creative solutions and planning at hand. The changes in wall thickness may cause inhomogeneous cooling resulting in stresses in the structure, warpages and dimensional instability. The problem is on how to have structural integrity and at the same time meet the design requirements of uniform thickness.

There are graduated changes in values of the wall thickness, to reduce stress concentrations and the flow features of the materials. Design engineers resort to complex tapering mechanisms and placement of the ribs in a careful location to ensure a perfect distribution of the thickness layer to keep the part functional.

Draft Angle Requirements and Applications

Draft angles enable easy part release out of the halves of the mold cavity, and there would be no damage to the part as well as to the mold itself. There are several factors which determine the needed draft angle such as the type of material, its finishing, part geometry, and the design of an ejection system. Inadequate draft may cause mishaps in the ejection of a part, distortion of part and early wear of the molds.

The consideration of a draft angle varies on different surfaces. Rough surfaces will tend to require steeper draft angles than smooth surfaces and deep holes may require gradual draft angles in order to permit correct ejection. Comprehension of these subtlety allows designers to maximize the utility of parts as well as manufacturing productivity.

Undercut Design and Side Action Systems

Injection mold design Injection mold design has both opportunities and challenges in undercuts. They allow advanced geometry and functionality and demand advanced side action systems or new molding technologies. This decision must be processed in the light of technical feasibility and economic considerations of the ensuing mold complexity involved.

Undercuts can be attained though the use of side action, such as slides and lifters, so that fully automated production is not lost. Such systems involve a lot of timing and coordination to yield a successful running of its use in the entire production cycle. The design engineer should be very sure of striking the right balance between part functionality and the complexities of the mold as well as maintenance needs.

Gate Design Principles and Placement

The type and location of injection molding gates design on a part could seriously affect its quality, look and production efficiency. Its structure is important in providing good filling, uniformity and size of lunar material in the cavity through the gate which is the inlet of molten material into the cavity. It is important to size gate correctly so that upstream material flows well, and not too much shear that would negatively affect material properties.

The site of slots influences cosmetic layout and the strength of the end component. Good placement of the strategic gates may reduce the noticeable witness mark and maintain the best flow patterns of the material. More complex gating methods, including hot runner systems and valve gates, provide more precise control of the injection process but entail a further complexity in making the mold.

Runner System Design and Optimization

The runner route acts as a highway between the injection unit where the molten material is and the part cavities. Good runner design minimizes the wastage of material, shortens the cycle time, and guarantees the desired part quality in all the cavities. The shape, size and surface finish of runners also facilitate the overall system performance.

The alternating unhypocycloidal and equal delivery of the runner systems into all bottle-like cavities of a multi cavity mold enables consistently good part quality and minimizes risk of defect. The design of advanced runners includes such features as flow leaders and specific geometries to achieve the optimal distribution of the material and low losses due to the pressure.

Cooling System Design Excellence

Cycle times, part quality and indeed production efficiency are directly affected by the effective design of the cooling system, as well as considerations for material shrinkage . The cooling system in the injection molding machine should be able to remove heat in the molded part in an even way and also control the temperature within precision in the whole process. Poor cooling can lead to long cycle times, part warpage and instability of dimensions.

The conformal cooling channels feature a better heat-extraction volume due to their track following the shape of part geometries in contrast to the conventional straight-line cooling channels. Modernized methods in manufacturing such as 3D printing and electrical discharge machining allow generating complicated cooling geometries that could not be achieved earlier.

Venting System Requirements

Accentuated air entrapment does not occur when proper venting is practiced, and sufficient air is not trapped inside the cavity. Vents should not be so poor that it leads to insufficient fill, burnt marks, and low-quality surface. The venting system should strike the balance between air evacuation and elimination of material flash, and this entails careful control over the dimensions and physical location of vents.

Ways of venting differ according to the geometry of parts, material characteristics, and limitations of a mold plastic resin. Contours and complicated geometry can necessitate repetitive vent sites and novel vent design to guarantee ventilation of air during the filling procedure.

Ejection System Design Fundamentals

The ejection mechanism should be able to take out the molded components out of the cavity in a safe manner without damage, deformation. The proper positioning, sizing as well as timing of the ejector pin also helps in part ejection. The ejection force should be spread uniformly all around the part to avoid stress concentration causing damage of a part.

More particular ejection mechanisms, such as stripper plates and air ejection, provide various solutions to dedicated tasks instead of regular ejector pins. There could be benefits of system part quality, ability to automate or maintenance of the molds.

Parting Line Optimization

Parting signifies the area that touches between two mold halves and it has a major impact on the look of the portion and complexity of the production. The right selection of parting lines allows reducing visible marks and improving the cosmetic appearance, easing the design of the mold as well as decreasing the cost of manufacturing. There are impacts of parting line location with respect to draft and ejection system design and the complexity of the whole mold.

Parting lines can be complex and need stepped or angled parting lines to fit the geometry of the part and still seal properly. Complex parting line developments may have such features as shut-off angles and special sealing surfaces to eliminate the problem of material flash and assure uniform part quality.

Surface Finish Considerations

Mold is also designed based on the surface finish requirements with regard to the selection of the material, and machining according to such requirements. Various surface textures demand certain draft angles, venting methods and ejection issues, especially when using pre hardened steel molds . The desirable surface finish should be weighed against the feasibility of manufacture and cost limitation.

Surface textures may aid in appearances and functions of parts as well as concealing minor deformities. But more textured surfaces will usually demand steeper draft angles and possibly special ejection mechanisms to avoid damaging parts during ejection. The depth of texture and the pattern intricacies influences the cost that is incurred in the manufacturing of the moulds as well as the maintenance cost.

Tolerance Analysis and Control

Attaining fine tolerances during Injection molding involves paying extra attention to material contraction, processing deviations, and wear-down of molds. When several parts have to be assembled and where the sizes of individual parts are critical, then tolerance analysis should take into consideration the assembly requirements additionally to individual part dimensions. The functional requirements should be balanced with the cost effectiveness of tight tolerances to the economy.

Measurement advancement allows monitoring and optimization of dimensional accuracy during production by using statistic process control as well as advanced methods of measurement. Specification of tolerances in relation to part designed should be done by engineering designers in view of this that they should specify practical tolerances that satisfy their functional needs on the product designed in view of manufacturing constraints and cost issues.

Multi-Cavity Mold Design Strategies

The multi-cavity moulds allow high volume manufacture efficiency and must be well designed to perform well with all cavities producing the same level of quality. Successful operation of multi-cavity requires balanced runner systems, uniform cooling and synchronized ejection. The number of partings has to be optimized in terms of the size of the part, material characteristics, and needs of production.

Variations between cavities may be due to variations in the length of the flow path, cooling efficiency or timing of ejection. High levels of design technology and in process monitoring are used to mitigate against these variations so that quality of parts remains consistent during a production phase.

Hot Runner System Integration

Hot runner systems rather do away with the runners because they ensure the molten substance remains in the heated channels all through the molding process. These systems decrease wastes of materials, eradicate second activities and accelerate cycle times. But hot runner systems use advanced temperature control systems and require special servicing routines.

Integration of hot runner system has a lot of implications to mold design, including thermal management, accessibility to maintenance. Design engineers should look at the short-term advantage and long-term effects of the hot runner and this involves energy, maintenance costs and system reliability.

Simulation and Analysis Tools

Injection molds are predominantly designed using high end simulation software to allow prediction and optimization of performance prior to actual construction. These tools allow effective exploration of the material flow and the cooling, prediction of warpage in the system, and stress distribution. The results of simulation inform the design and could help ensure that a problem during the early period of development could be detected.

Simulation results rely on adequate material property data, boundary conditions and quality mesh. The design engineer should be knowledgeable on the capabilities and weaknesses of simulation tools to be able to make use of them properly in the design process. The simulation evaluation should be understood as validation to the physical testing in the critical applications.

Quality Control and Testing Protocols

Diverse quality control standards develop a steady production of good parts. These procedures include some dimensional checking, material attributes check, and functional testing. The quality control plan should be implemented in the design stage, which means that the required features and access will be introduced into the design of the mold.

The statistical process control methods allow real-time inspection of the quality in production and detection of trends that could suggest emerging problems. Additional measurement methodology, such as coordinate measuring machines, and optical inspection systems allow in-depth quality analysis.

Cost Optimization Techniques

Cost optimization in an injection molding project involves trade-offs between the cost of the injection molding materials tooling compared to long term cost of efficiency in the production and the quality of parts. With the use of value engineering techniques, the opportunities of reducing the costs without compromising on the functional requirements are identified. The cost of ownership is total cost not what it is regarding the initial price of molds but also considers maintenance costs, energy cost and effectiveness of production.

The principles of design to manufacturability allow decision-making that decreases the complexity of the molds without impairing the functionality of the parts. It is possible to minimize both start up and maintenance costs, since components and features can be standardized. Comprehensive material selection including glass fibers and processing parameters optimization boost wholesome cost effectiveness.

Injection molding process Maintenance and Serviceability Design

Maintenance design and serviceability will assure the long-term mold performance after maintenance and lower operation cost. Easy access ports or doughports and modular constructions as well as standardized maintenance routines help efficient mold operation. Predictive maintenance practices are able to detect problems in advance such that they do not lead to production downtimes plastic injection molding.

The maintenance should be considered early in its design instead of it being a more follow up thought. Simple access to the wear parts, effective service routines, and well-documented maintenance also mean successful long-term work.

Sink marks Material Flow Analysis

The recognition of the vehicle of substance utilizing is vital in enhancing the location of gates, runner design, and general mold design. Flow analysis can be used to establish the possibility of forming weld lines, air traps and incomplete filling. The modern tools of simulation allow the detailed visualization of the flow picture and allow optimization of design parameters.

The characteristic of the material flow is strongly characterised by the various kinds of plastic materials and processing conditions. In analyzing the flow patterns and designing better molds, design engineers have to keep in mind the viscosity, the sensitivity of the material to temperature, and the content of the filler.

Thermal Management Strategies

Efficient thermal control leads to uniformity in the part quality and optimal cycle improvements. Temperature control influences the material flow, the rates of cooling and properties of the parts. Such advanced methods of thermo-management are conformal cooling, variable temperature control and treated heating systems in difficult applications.

Thermal analysis tools are beneficial in predictions of a temperature distribution/hotspot or cold zones that may cause part quality issues. Thermal results lead to the designation of optimization of the design which leads to a more efficient cooling system and a general increase in performance.

Defect Prevention and Troubleshooting

The design-based measures of defect prevention are better than detective measures taken later in the production. Sink marks, warpage and flash are typical problems that may be avoided by close observance to design specifications and process conditions. Recognizing the causes of the defects allows intra-design variations to fix it.

Problem-solving manuals and step-by-step troubleshooting methods can also be used to find and solve the various problems with production. Design engineers must also be able to predict the most likely problems and design capabilities that would enable them to carry out simple troubleshooting and correction of the problems as they come.

Advanced Design Techniques

Innovative design processes expand the limit of injection moulding potentials. Such methods encompass the multi-material molding, in-mold assembly as well as advanced surfaces treatment. These methods provide better functionality, but they need advanced design skills and also special equipment.

New technologies like additive manufacturing producing molds and more advanced simulation solutions are still increasing design opportunities. Design engineers need to keep up with current technological trends in order to ride on new potentials.

Environmental and Sustainability Considerations

Sustainable mold Creation takes into consideration the environmental impact during the life process of the product. This encompasses the choice of materials, energy conservation, minimization of waste and after life. Design choices that minimize wastage of materials, allow the products to be recyclable and require the least amount of energy are also relevant to the ultimate aims of sustainability.

Life cycle assessment tools are useful in measuring effects on the environment and in informing design choices to more sustainable alternatives. Mold design and selection of materials to use are increasingly being subjected to regulatory requirements as well as corporate sustainability efforts.

Automation and Industry 4.0 Integration

Injection molding nowadays becomes more and more automated and utilizes smart technologies of manufacturing. Molds should be designed to hold automation handling system, inline quality inspection and process monitoring in real time. Predictable maintenance, optimization, and improved quality control can be achieved using industry 4.0 technologies.

Such combining of sensors, data harvesting and automated feedback requires thought at the mold design stage. The design engineers should be ready to meet automation needs and add features to integrate without problems with smart manufacturing systems.

Regulatory Compliance and Standards

Design of an injection mold should be within the industry standards and regulations. Depending on the application, different requirements have to be met, medical devices, automative components and food packaging that need to have certain compliance requirements. Knowing the regulations before the design is well-developed saves unnecessary alterations down the road.

The documentation and traceability needs influence the mold designing and the production process. The design engineers should consider that documentation and validation activities needed should be integrated in the entire design and production process.

Global Manufacturing Considerations

The manufacturing on the international level is sufficiently challenging in terms of materials and processing capacities as well as quality requirements. Molds should be designed ignoring regional variation in materials, equipment and manufacturing. Global manufacturing networks need to be well documented and have standardized procedures in terms of communication and coordination.

Communication on designing requirement and manufacturing specifications may be influenced by cultural and language differentials. To achieve a successful implementation of global manufacturing design engineers should formulate efficient communication strategies and documentation system.

Future Trends and Innovations

New materials, processes and technologies also develop an injection molding industry. The new trends are bio-based materials, advanced composite, and hybrid production. To use newly available possibilities and stabilize competitive advantages, design engineers need to be aware of industry trends produce plastic parts.

Machine learning and artificial intelligence in designing molds and optimization of the process constitute a huge potential of improvement. Such technologies can process large volumes of data to assess opportunities of optimization and provide performance outcomes prediction in a more accurate manner, as compared to the traditional techniques.

Digital Twin Technology Applications

When applied to molding, digital twin technology generates digital copies of physical molds and processes to profile or improve it in real time. These virtual models are capable of predicting the performance, defining maintenance requirements and determining the optimal processing parameters using actual production data hot tip gates. To implement a digital twin technology it would involve integrating it at the designing stage.

Some of the advantages relative to digital twin technology are minimized downtime, better quality control, and understanding of the process same mold. Nevertheless, it will demand considerable expenses on sensors and data collection/processing and analytics sharp corners.

Risk Management in Mold Design

Successful risk management will reveal the anticipated problems at initial phases of the design process especially with the use of threaded inserts and will develop mitigation measures thick walls injection molding cycle. Technical, commercial and operational issues that may influence the success of a project should be factored in risk assessment. Flexibility in the design and contingency planning serve to consider the unforeseen problems that occur in the process of development and production.

The strategies of risk management involve testing a prototype, phased implementation of needs, and designing validation. Spreading the word about risks and avoidance measures to all the stakeholders will mean that informed decisions are made in the entire lifecycle of the project.

Cross-Functional Collaboration Strategies injection molding project

Design of injection molding involves cooperation of various professionals who are designers of engineering, manufacturing, quality and commercial department. The best communication and coordination will result in ensuring that all needs and limitations are put in consideration during the designing phase. Delays and modification that may be costly are avoided by courting early participation by all the stakeholders..

Distributed teams Communication and coordination between distributed teams is enabled through collaborative design tools and practices. Periodic reviews and milestone review also enable timely project checks to aid in ensuring that the projects are running as scheduled and all the requirements needed are in the process of being addressed.

Performance Optimization Methods

The optimization of the continuous performance will support the molds to work to the highest levels possible during their service life. The performance metrics are cycle time, quality of parts, energy consumption and the maintenance needs. The data-driven optimization method involves the use of production data to find opportunities of improvement and verify changes in the design.

The methods which can be used in optimization include parameter changes in processing, cooling system adjustments, or design adjustments to actual production experience. Periodic performance analysis and improvement programs keep competitive edges and sustain a long-term success.

Documentation and Knowledge Management

Design rationale, manufacturing specification and operations procedures are documented comprehensively. Knowledge management tools are effective in making sure that important information is retained and can be made available to future and the current members of the team. Quality control and continuous improvement initiatives via documentation standards and practices reaffirm regulatory compliance.

Knowledge management is also not just related to documentation but can also be associated with best practices, lessons learned and institutional knowledge. Organizations need to devise methods of hanging on to and transferring knowledge in order to keep the capability of design and not to repeat the things that went wrong earlier.

Заключение

Design of injection molding is a complex interruption of crossover engineering capabilities, manufacturing and business constraints. This field needs high level of technical expertise along with manufacturing experience and proper communication skills. The information contained in this detailed guide in the form of guidelines and principles that govern the development of molds that will offer high performance and efficacy as well as quality and value.

There is a need to keep on learning and adapting due to the constant stream of new materials evolved, processes, and technologies. Design engineers need to be in touch with current industry trends and at the same time keep on the basic principles of providing assurance of the reliability of the manufacturing solution at a cost-effective level. When these guidelines are applied equally and adjustments made to suit the need of specific applications the manufacturers will be able to carry out exemplary injection mold design and manufacture.