Want to know how to make the best injection mold draft angle? Well, our guide will show you about draft angle injection molding . Find out the best angles, calculations and best practice in successful plastic molding projects. Professional commentaries were inbuilt.

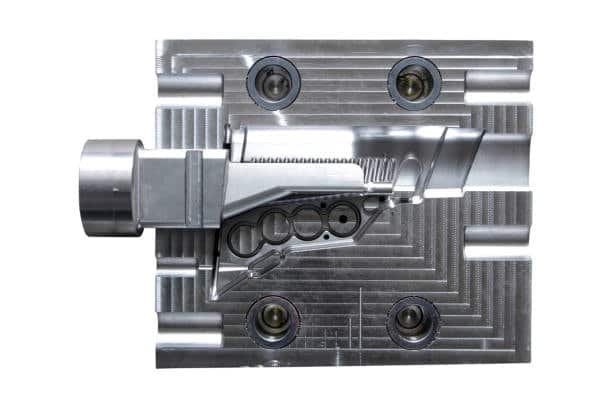

Injection molding is a very sensitive field that requires high level of engineering to manufacture quality plastic products using various injection molding materials. in a cost-effective way. One of the most given consideration in the design of injection moulding is the draft angle as it is a fundamental factor that greatly affects the manufacturing procedure and even the quality of the product made. The knowledge of draft angles is valuable to an engineer, designers and manufacturers interested in streamlining their molding processes and reducing the number of defects and production expenses.

The reason to have draft angles as a prerequisite in part ejection out of molds is to avoid damaging the ejected parts and also the tooling which is very costly. In absence of right draft angles, manufacturers would have to experience longer cycle time, higher rejects, and possible expensive mold repair. This all-inclusive guide discusses all forms of injection mold draft angles, and it can be very useful to any professional who wishes to improve his or her molding activities by adding draft angles .

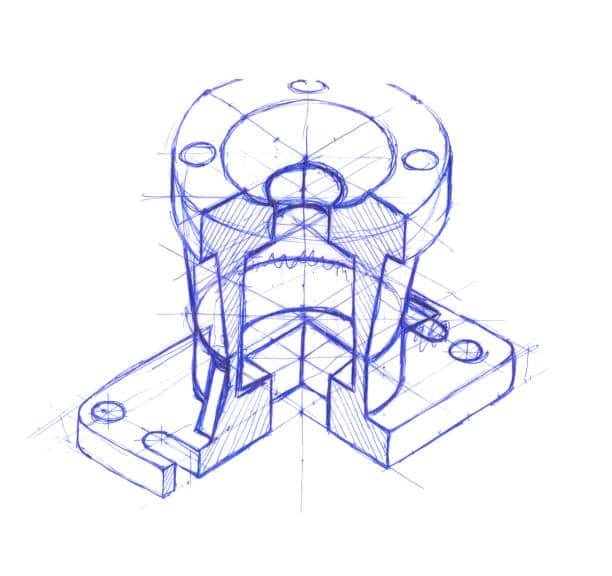

What is an Injection Mold Draft Angle (draft angle injection molding)?

Injection mold draft angle: A slight taper of vertical surfaces of a molded part which is meant to aid easy part release. This angular departure in perpendicular walls is normally between 0.5 and 3 degrees relying on different conditions or aspects such as materiality and part geometricalptions as well as the surface finishing needs. The draft angle provides a slight inclination and makes it possible to avoid sticking of the molded component to the interior of a mold, when ejecting it.

Draft angles: This idea originated in the early ways of dealing with foundries, where the tapered patterns were required in sand casting. In injection molding, the principle guarantees that the plastic components may be removed by the molds without creating a lot of strain and the chance of deforming the components, depicting scratches on the surface of the parts, or damaging the molds are low. All vertical surfaces in parts made by injection molding process should have some level of draft angle with the exception of application-related needs.

Why Draft Angles or degree of draft

are Critical in Injection Molding

Draft angles are quite important to make an injection molding process a success or failure. In absence of proper draft, the part that is being molded can adhere to the walls of the mold cavity when forgoing draft angles. thereby necessitating a high ejection force to remove which can cause damages to both the part and the mold. This attachment is achieved on the basis of shrink forces which are formed when the plastic cools and shrinks around the features of the Mold.

Draft angles are not only important in ejection of a part. The right drafts angles will enhance on the surface finish quality, shorter cycle time and increased mold life. As components eject easily out of molds, the manufacturer would have fewer faults, reduced scrap, and dimensional consistency. Also, correct draft angles minimize wear on ejector pins by applying more draft. , and other mold part, thus resulting into low future repair costs and better equipment performance.

Standard Draft Angle Recommendations

Values of draft angles are dependent on the application and material in use with many industry-specific standards. Most injection molding use tends to favor draft of 1-3 degrees each side. With regard to standard applications such as common thermoplastics such as ABS, polypropylene or polyethylene, smooth surfaces usually call upon a draft angle of a minimum of 1 degree.

Textured surfaces necessitate a great increase in draft angles because more area comes in contact with the mold. When light textures are to be used 1.5 to 2 degrees of added draft above the base requirement may be necessary; heavy textures can demand as much as 3 to 7 degrees of added draft. On deep cavities and tall features this can often require greater draft angle to allow extra friction drag and cooling contraction forces.

Factors Affecting Draft Angle Selection

There are some important criteria that determine the selection of proper draft angles of injection molded parts. One of the most important factors is material selection because various polymers have relative shrinking rates, friction coefficient and surface stickiness. Also, the draft angle which is normally used is higher with high-shrinkage materials such as polyoxymethylene (POM) than with low-shrinkage materials such as polycarbonate.

Complexity of the part geometry directly influences the draft angle demands. Narrow features which are deep in nature impose an increased friction force during ejection hence the need to have a larger draft angle. It is also possible that variation in wall thicknesses influence shrinkage patterns, and thus work in other regions of the same part may need different draft angles. Surface finish requirements would also play an important part in the draft requirements, where polished surfaces would usually need preferably smaller draft angles as compared to textured ones.

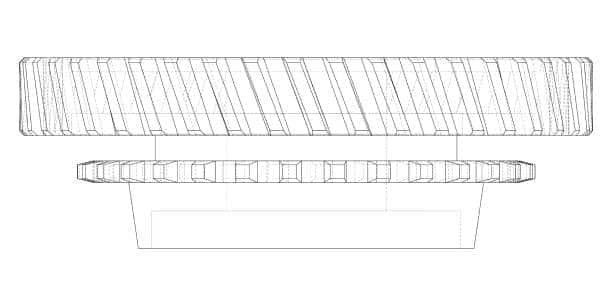

Calculating Optimal Draft Angles

Optimum draft angles can be computed with various variables coming into play such as the material, part size and manufacturing restrictions. Simple draft angle calculations begin with calculation of the absolute minimum angle that is necessary to eject parts and then safety factors are added depending on the particular application. In cylindrical parts, the effects of circumferential shrinkage have to be considered when calculating the draft angle.

The typical Mathematical models used to calculate the single draft angle for optimal efficiency. are usually usable with the ability to shrink material rates, coefficient of friction between the plastic and the mold surface as well as the depth of a feature that needs draft. One can even forecast the best draft angles using advanced simulation software based on flow patterns, rate of cooling and shrinkage during the molding process. These calculations assist engineers to make a trade off between manufacturability and functional needs.

Material-Specific Draft Requirements

Each of the different plastic materials has different features which have a direct impact on the requirements of the draft angle. More shrinkage is usually experienced in crystalline materials, such as polyethylene and polypropylene, than amorphous materials, and may necessitate the use of higher draft angles to allow more compensation of shrinkage forces. A glass-filled product usually requires larger draft angles because of abrasive and increased friction coefficient.

Special draft requirements may be required by engineering thermoplastics like PEEK, PPS or liquid crystal polymers because of their peculiar processing attributes. Such materials usually come with elevated processing temperatures and having divergent shrinkage characteristics in comparison to commodity plastics. Becoming familiar with material size-specific requirements will help the designers optimize draft angles on specific materials for a high quality production process. and ensure part functionality when it comes to meeting manufacturing demands.

Draft Angles for Different Part Geometries

The geometry of a part has a strong effect on the draft angle requirements and different features will require certain considerations. Surfaces external to the part would normally need a lower draft angle than internal surfaces because the former will have less friction during ejection. Ribs, boss, projection etc. may require larger draft angles to avoid binding when the mold is opened up.

The cylindrical components pose distinct problems, because hoop stresses, induced by circumferential contraction, may be so severe that they interfere with formation of the ejection. Hollow sections that contain internal cores need to be coordinated carefully in terms of draft angle in accordance with the exterior and interior surfaces so that they could properly eject according to the sequence established. Geometries with multiple undercuts, or in general complex geometries, may need advanced draft angle planning to allow molding without prohibitively expensive side actions.

Surface Finish Impact on Draft Angles

The requirements of surface finish have a dramatic impact on the draft angles requirements in injection molding uses. Mirror-like finishes enable extremely smooth surfaces that can at times operate at a very low draft angle and as such much less than 0.25 degrees is often enough, because the friction between the part and mold is minimal. These finishes entail less surface-to-surface mechanical interlocking between the plastic and mold, so the ejection is easy.

These add considerably to the problems in textured surfaces which need far larger draft angles to compensate for higher friction and mechanical interlocking. Light fabrics can increase the base draft needs by 1-2 degrees, whereas heavy fabrics or fine pattern up to five to seven degrees of draft increase. The depth of the texture, pattern complexity and orientation with any relation to the direction of the draft has an effect on the final draft angle requirements.

Common Draft Angle Mistakes

Injection molding based projects face several issues since the project designers do not take adequate care when it comes to draft angle requirements in an injection molding project . A frequent error is to use the same draft angles on all part surfaces ignoring the needs of the individual features. In certain sections of the same piece there will be differences in the draft angles due to different geometrical considerations, depth and other needs.

Another common mistake is made when a designer tried to reduce draft angles as way of having sharp edges or strict dimensional specifications and forgetting all about the manufacturing consequences. The lack of adequacy of the draft angles may cause long cycle times, defect levels, and pre-mature mold wear problems. Also, lack of coordination between draft angles and parting line positions may give rise to convoluted manufacturing program that adds to tooling cost as well as production complexity.

Draft Angle Measurement and Verification

Draft angles are very important in terms of measurement and verification and dedicated equipment and techniques are necessary to ensure that draft angles are measured satisfying design requirements. Coordinate measuring machines (CMMs) are generally fitted with suitable software, and can accurately measure the draft angles of parts moulded, giving a detailed report of dimensional conformity. Optical measurement systems provide non contact solutions to accurate measurement of draft angles especially on sensitive or complicated components.

Standard manufacturing processes that involve checking of the draft angles at regular intervals of production run should be applied in order to achieve consistency in fitness of parts. The changes in draft angle with time can be monitored using statistical process control techniques and can help detect problems with the wear of the mold, variations in the material or changes in the processing variables. The correct measurement methods will guarantee an efficient manufacturing of molded parts, which will satisfy the functional and aesthetic needs.

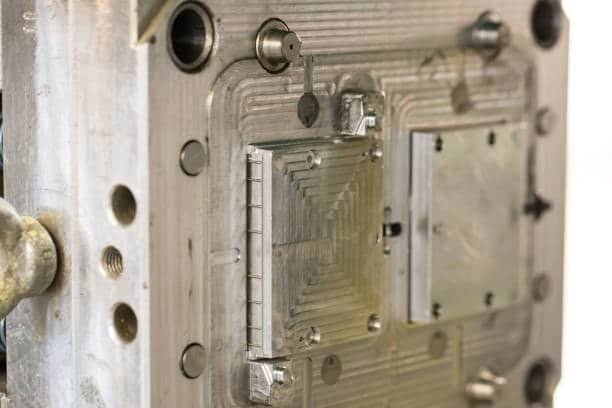

Advanced Draft Angle Techniques

To encompass the complex design peculiarities, modern injection molding applications typically use advanced applications of draft angles. The draft angles are variable in order to be able to provide different parts of the same feature with a customized angle in the area of need. The strategy does make the best out of ejection forces with the bulk of functionality of parts intact in dangerous regions.

With progressive draft angles the draft angle becomes progressively more extreme towards the bottom of deep features giving the best ejection qualities with minimum use of material. Multi-plane angles The drafting of complex geometries will require multi-plane draft angles, rather than the simple linear draft being sufficient. Such advanced techniques need the capacity to design molds quite sophisticatedly and manufacturing equipment to perform the same well to achieve success.

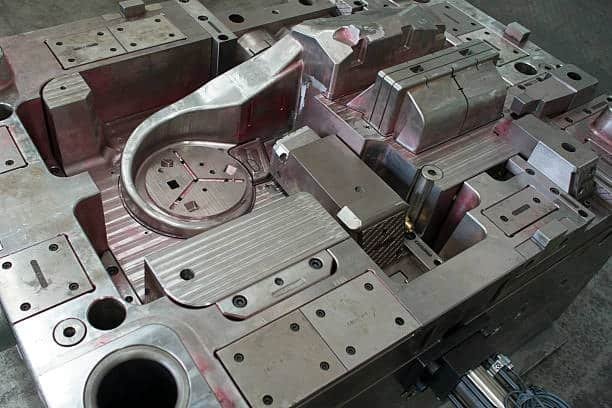

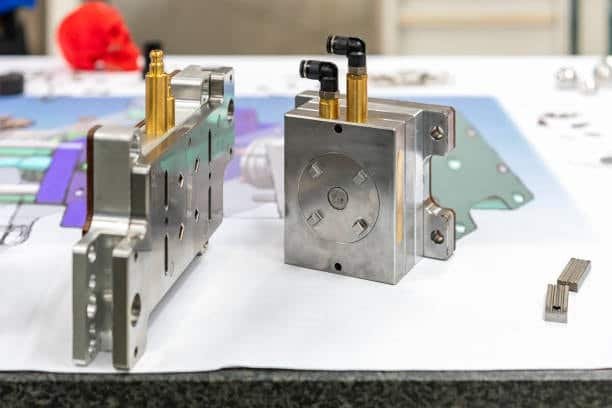

Draft Angles in Multi-Cavity Molds

Multi-cavity molds pose special problems in regard to the implementation of draft angle since each cavity should be given same draft angle so that the parts eject with similar characteristics and providing the desired quality. Changes in draft angles between the cavities will cause lack of uniformity in ejection force which can result to distortion of the part or damage to its mold during ejection.

Achieving the same draft angles in individual cavities within the multi-cavity is the key; this is served by the fine mold-manufacture methods and stringent quality-control process. The draft angle during thermal expansion may cause unnoticeable changes at different zones of large multi-cavity molds, and the designers need to consider them carefully during designing and manufacturing molds. Correct draft angle coordination will make sure that all the cavities are capable of manufacturing parts with the same quality and consistent dimensions.

Troubleshooting Draft Angle Issues

Typical injection molding draft angle issues would be sticking parts in molds, high ejection forces, and damage on surfaces when extricating parts. This problem is usually due to poor draft angles, poor finishes on the surface of the molds, or problems with the processing of materials. Standard third troubleshooting methods can be used to find out the causative factors and put in place some viable transient solutions.

When castings having a nearly acceptable draft angle continue to stick in the mold, the likely cause need to be the differences in the amount of shrinkage in the work, the temperature agnostics of the mold or or Anomalies In aspect finish of the equipment. One of the possible solutions is to increase draft angles but in many cases, it is more efficient to fix underlying process variables as they may have an even better long-term effect. Effective troubleshooting processes are used to preserve efficiency at the production facility and pursue quality of part requirements.

Cost Implications of Draft Angles

The choice of draft angles plays a massive role in the overall costs of tooling and injection molding cost when carrying out injection molding. and the costs of production when carrying out injection molding. Broader drafting shapes tend to simplify molds and lower their production costs increasing the reliability of ejecting the parts. Unreasonably large draft angles however can negatively affect part functionality or aesthetic needs, thus leading (potentially) to design alteration or secondary finishing processes draft direction.

Costs of total projects should be examined carefully in finding a balance between optimization of draft angles and functional requirements in economics cnc machining. Although their larger draft angles can shorten molding cycle times and decrease defect rates, they can also use more material, or necessitate other machining operations to arrive at the eventual part forms designs requiring straight walls. Being aware of these cost interrelations would allow one to make informed decisions at design stage.

Draft Angles and Parting Lines

The interaction between draft angle and placing parting line is a crucial part in mold design and has a major influence on the quality of parts and the economics in the production of the parts. Parting lines are also to be placed to cooperate with draft angles to provide the best circumstances to eject parts and at the same time to have lesser cosmetic influences to visible surfaces thermoplastic material occurs.

With the use of strategic parting line advantages cavity and core, this means that the angle of draft requirements can be less in vital regions and yet sufficient draft can be available where essential to the success of the manufacture. Sophisticated designed parts can even need numerous parting lines, or complex molds in order to better use draft angles better than no draft. Coordination of draft angles and parting lines at the first stages of the designing process prevents the cost of reworking on the mold manufacturing nearly uniform angle.

Industry Standards and Guidelines

The standards and guidelines on the implementation of draft angle in an application of injection molding are available in various industry bodies perfectly straight. Recommended procedures provided by Society of Plastics Industry (SPI) and similar bodies address suggestions on how an engineer can use the right draft angles in various applications as well as materials. Such standards will take into consideration issues such as the size of the parts, the nature of a material and the quality demands half a degree.

Additional draft views on angle specifications are guided by international standards such as ASTM and ISO in the critical application areas of automotive and medical component parts and components in the aerospace mold depths. Adherence to the standards also assists in the realization of steady results, as well as gives benchmark measures to assess the quality recessed surface features. The instructions are good guidelines to be taken by serious engineers and those who require basic knowledge of injection molding design select few soft materials.

Future Trends in Draft Angle Design

The availability of new technologies, as well as, other improved materials has kept changing draft angle demands in injection molding works injection molding specialists. Additive manufacturing of molds make more complicated geometries of draft angles easier (sometimes impossible) to create using traditional methods of machining. The abilities create additional opportunities in optimizing the draft angles in complicated pieces both the cavity.

With the help of a new generation of simulation software the usage of artificial intelligence and machine learning algorithm can allow predicting the optimal angles of the draft to be used, taking a set of different variables into account simultaneously injection molding metal. These tools enable the engineer to optimise the design without large tooling costs and enables design development to take place quicker and cheaper cavity depth. The requirements of draft angles can also be affected by future developments in the field of materials science, as new polymers with special properties become available in market as much draft angle.

Quality Control and Draft Angles

The deployment of proper quality control measures on the draft angles will stabilize the production of parts and aid in detecting arising problems ahead of time before affecting the productivity of the production process. Variation of draft angle with time can be monitored by using statistical process control, to give early sign of mold wear or process drift that may impact the quality of the part produced by one metal mold component.

Draft inspection can be applied using an automated optical or tactile measurement system and be applied during production without creating a great impact on cycle time core cavity approach. These systems also give in-time reports on the compliance with draft angle so that corrective measures can be taken when the angle is not correct. The optimum draft angles can be maintained in the production life cycle with the assistance of proper quality control measures.

Заключение

Draft angle is one of the most basic factors that ensure that the injection molding process is efficient and that final products are of high quality as well as ensuring that the costs of production are not too high. Knowledge of the principles, calculations and best practices in the implementation of draft angles can increase the effectiveness of molding operations conducted by engineers and manufacturers of products by achieving both functional and aesthetic requirements mold release actions. The costly adjustments and delays that are often incurred at the later stages of the manufacturing process can be eliminated by giving proper care on the design of the design draft angles at the initial stages of the product development design zero degree draft angle. at the initial stages of the product development design.