Meta Description: Find out the main contrasts in overmolding and insert molding, both of which are a popular manufacturing process . Donor applications, advantages and disadvantages, costs and how to select the best manufacturing process to use in your projects.

Optimal excellence in manufacturing is a state that needs clear knowledge on the ways of production that can provide quality and efficiency, in the current competitive world. Insert molding and overmolding, and also two shot molding, are two important processes which usually derail manufacturers and designers. Although both methods relate to mixing of disparate materials to fabricate operative elements, it transpires that they have varying purposes and benefits based on requirements of the application.

Insert molding and overmolding are two of the advanced manufacturing techniques that have transformed our production process to give us advanced products that are multi-material and can effectively incorporate multiple materials. Applied to automotive components, consumer electronics and other products, these processes allow the fabrication of parts that could otherwise neither be produced or not economically possible to manufacture using traditional assembly-based systems. Knowledge of the differences between these methods is the key to making informed choices that will influence the performance attained by a product, cost of different products and competitiveness in the market place.

Intentions to use insert molding or overmolding, which can be considered as a two step process, will probably define the success or failure of a new product. Every process has its own capabilities, its limitations, as well as cost factors, which have to be adequately considered against a project requirement. This handbook highlights every element of each of the two techniques and equip a person with knowledge to arrive at strategic manufacturing decisions based on goals of the business and the technical requirements involved.

Understanding Insert Molding Fundamentals

Insert molding is an advanced manufacturing procedure in which a pre-fabricated part (or component), often including metal inserts referred to as insert, is inserted into a cavity of a mold prior to injection of plastic. These inserts are surrounded by the molten plastic and form a permanent mechanical bond moving many materials into one composite functional element. This process could exclude the secondary process of assembly and could provide the accuracy of positioning and durable fixing of various materials, resulting in a single bonded component .

Insert molding starts by thorough preparation of the materials that will be inserted into the mold; these can consist of metal threads and electronic components, or fabric items or any pre-formed parts. These inserts, including threaded metal inserts, should be prepared in such a way that it would use the temperatures and pressure that would be involved during the injection molding in order to retain their structure, as well as functional characteristics. Mold design is important because it ensures inserts are in the right location and that the plastic would flow in a consistent manner around complicated shapes.

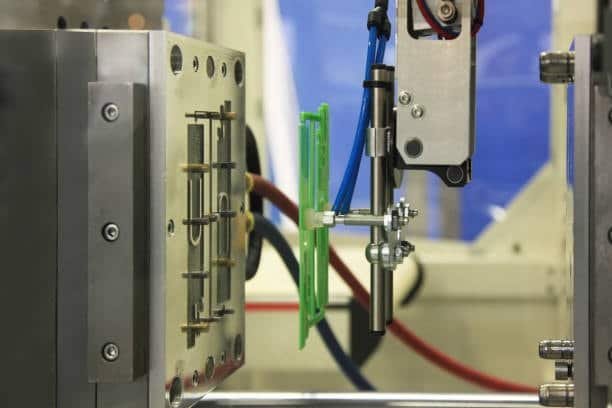

Insert molding needs stringent considerations to place inserts, suitability of material with the inserts, and parameters during processing. The final product is also due to the attainment of the best level of adhesion between the inserted materials as well as the plastic matrix without affecting the functionality of any of the two elements. High technology insert molding applications usually use automation to ensure accurate inserts location and to monitor the key process parameters in real time.

The contemporary insert molding characteristics allow more than straightforward mechanical solutions and cover multi-component electronic assembles, medical equipment, and vehicles parts. The procedure facilitates production of products whose functionality has been integrated via the use of several manufacturing actions and assembly procedures under traditional production procedures. This integration simplifies manufacturing but increases product reliability, consistency of performance, and can also be applied to soft seals.

Exploring Overmolding Technology

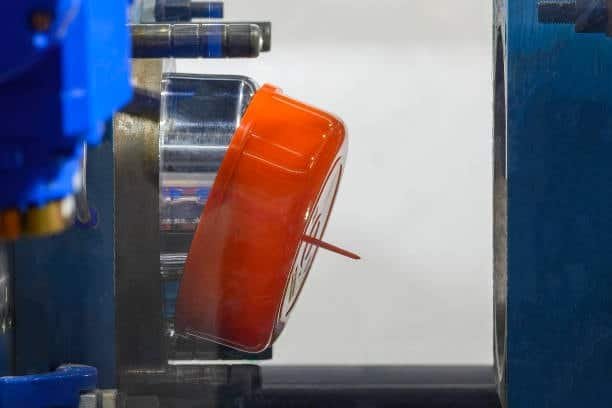

The technology of overmolding is based on the use of the primary material as the base and a second one as the layer on the top to achieve the planned functionality and to improve the aesthetic value, resulting in multi-material products. Overmolding, which may include thermoplastic elastomers, unlike insert molding results in multi layered sandwich like structures whereby different material have their own boundaries but there is mechanical and chemical bonding at the interface.

The process usually starts with a preliminary component that plays the role of a substrate to which the following materials are applied. Such substrate may be a plastic substrate, n already formed plastic assembly, a metal component or even a complex item that needs more layers of material on it to work better or just look better. The secondary molding should be well maintained in order to get the right adhesion mechanism that does not destroy the substrate beneath it.

The issue of temperature control is of essence when it comes to overmolding work and the secondary material should only be hot enough to achieve the flow and bonding, and should not cause any heat-related damage of the substrate material. Such a balance is maintained by tight injection parameter control, mold temperatures as well as cooling cycle to produce reproducible results each run. High end overmolding machines, often operated by a robotic arm, tend to include multiple heating regions and temperature controls to ensure good process conditions.

Selection of materials in the overmolding process requires compatibility with chemicals used, differences in thermal expansion and mechanical properties. The materials interface, especially in the medical industry, is also a possible point of failure which should be designed to handle expected service loads and natural environments. Multi-material bonding applications can be quite tough to realize successful overmolding operations and in many cases, it necessitates specialized formulation of materials and selection of material combinations.

Key Differences in Manufacturing Processes

The root distinction between insert molding and overmolding is the manner in which they treat integration of materials and the product architecture that follows. Insert molding produces the insert molded part where foreign materials are totally surrounded by plastic matrix, whereas overmolding constructs the structures with two or more components layered materials with separate boundaries and interfaces.

Another important difference between these techniques is processing sequence. In normal insert molding, at least one injection molding cycle is normally needed with all the materials being mixed together at once, but in over molding it is often desirable to modify the final result by subjecting the product to repeated processes and intermediate handling and quality control measures. This variation affects production efficiency, control of quality, and the ability to produce identical parts and complexity of the manufacturing process.

The level of equipment that is needed at insert molding and overmolding operations is quite different. Insert molding can make use of special tooling to precisely position inserts, and hold them in place during the injection cycle, overmolding may require multi-station equipment with the ability to process components through multiple injection processes. The automation capability and the complexity involved varies extensively with these methods.

The methodologies of quality controls should be altered to consider the peculiarities of a definite process. Quality control in insert molding centers on the accuracy of insert placement, the level of completeness of the encapsulation, and whether similar materials are used in the molding or molding process and are compatible, whereas quality control in overmolding concentrates on the ability of a bond to form between the materials used in overmolding, similarity of the layers of a molding or molding process and whether or not these layers are equal and stable throughout the transition of the molds used in the overmolding process.

Совместимость и выбор материалов

One of the vital intervening factors that tend to determine the success and possible adoption of insert molding and overmolding, has to do with material compatibility. The chemical and physical parameters in the various types of materials, such as those used for a rubber handle, to be used should also be appropriately matched to make sure of stable bonding and long-lasting performance of the service expected.

The coefficients of thermal expansion are significant factors in selection of materials in the two processes. The large mismatch between thermal expansion coefficients of different materials may produce internal stresses resulting in premature failure, delamination or loss of dimensional stability. To choose compatible material combinations, engineers should analyze thermal behavior under conditions of the anticipated operating temperatures range carefully to ensure the compatibility of materials.

The chemical compatibility involves both the consideration of the molecular interaction, surface energy as well as the possible products of degradation reactions among dissimilar materials. Mechanical compatibility of material pairings can result in long term degradation of a material interaction because of the chemical interaction over an extended period or in a special environment.

When treating surfaces and treating their surfaces, the choice of the two can be quite influential on material compatibility in terms of problems in insert molding and in terms of overmolding. The bonding strength and reliability between otherwise incompatible materials may be enhanced by a technique e.g. using plasma treatment, chemical etching or primer application. All these preparation steps should be incorporated into the whole process of manufacture so as to produce consistent results.

Design Considerations and Requirements

Designing insert molding and overmolding must take into serious consideration the patterns of metal flow, the behavior of the heat and the distribution of mechanical stresses. The shape of the main piece and the material contacts noteably influences the manufacturing possibility and the performance level of the end product.

Varying line thickness is a problem in both processes. Insert molding must take into consideration plastic flow around embedded parts and overmolding must take consideration of material build up at interface areas. The variants in thickness may result in lower or higher cooling rates which cause internal stresses and dimensional deviations.

The angles of draft and surface finishes should be projected keeping in mind the requirements of the specific process. Insert molding sometimes needs altered drafting angles around areas with embedded parts, and overmolding usually needs improved surface preparation to ensure good bonding. Such design specifications have a great effect on feasibility of manufacturing and cost of production.

The interaction between diverse rates of thermal expansion and the processing conditions makes tolerance considerations more complicated in multi material applications. Tolerance stack-up should be conducted across material interfaces of plastic parts by the design teams and an applicable amount of compensation should be implemented in order to meet the final product dimensional requirements.

Quality Control and Testing Methods

Insert molding Quality control revolves around determination of proper insert position, total encapsulation and soundness of interface between the plastic matrix and embedded elements. Internal structural quality can be observed using non-destructive testings like the X-ray examination and ultrasonic examination that does not interfere with the integrity of products.

The overmolding quality control focuses on bonding strength between interfaces, layer uniformity and bond strength between material layers. Destroyed testing like the peel testing and cross section analysis will give quantitative information on the performance of bonding and the non-destructive testing method will allow the determination of possible problems within the production units.

With multi-material products, environmental testing is of special relevance because of the risk of different responses to temperature, humidity, and chemical exposure. Environmental cycling tests and accelerated aging tests assist in the verification of the long-term performance and the possible failure mechanism of manufacturing products prior their arrival in the market.

Statistical process controls used in the manufacturing scale need to be modified to match the peculiarities of multi-material productions. Process monitoring systems and control charts should also consider how the various processing parameters interact with the various materials to ensure consistent quality over multiple production runs.

Анализ затрат и экономические факторы

Insert molding and overmolding cost analysis should factor in the direct cost of manufacturing in addition to other indirect costs like quality control, complexities of the tooling system and efficiency in production. Special insert placement mechanisms, and complex shapes of the molds, often mean that the initial tooling investment in insert molding is higher than in other molding processes.

The difference between the processes in labor costs is also quite large as insert molding usually demands more competent labor to place the inserts and assure the insert quality whereas overmolding might need extra stages of handling, and quality checks good to tight. The degree of automation varies by process, and insert molding provides more potential to develop fully automated production systems.

The impact on total costs of production in relation to material wastage needs to be an issue in overmolding where the runner systems and possible rejection rates of materials used in the production process can be colossal and a problem. Recycling and reuse of material, especially in terms of achieving lighter weight, may differ in a process and may have a significant influence on long-term cost-structures.

The fixed costs of supplying tooling and set up are an important factor in process choice when the actual production volume becomes part of the calculation to allow amortization cost over volume. Insert molding can be desirable with high-volume applications as a result of being potentially automated, which helps reduce assembly costs ereas overmolding can be preferable in lower-volume applications because they are flexible.

Industry Applications and Use Cases

Use of both insert molding and overmolding in the automotive industry is only increasing, with manufacturers trying to use less of both, but achieve more through the production of less assembly parts with highly optimized performance and functionality. Insert molding is widely utilized in: Electronic control modules; Sensor assemblies; Structural parts which need to be metal reinforced or have threaded fits.

In medical device manufacturing, the two processes are greatly vital to the manufacture of sterile, biocompatible items that include functionality integrated into them. Insert molding allows the buildup of devices that include embedded sensors or conductive features: over molding allows soft- touch surfaces and grip improvement of surgical tools and patient interface equipment.

Consumer electronics also use the two techniques to make products that are more aesthetically appealing, functional and durable. Insert molding facilitates the addition of metal shielding and electrical connections and overmolding offers weather sealed, impact resistance and additional user interface features.

These processes are applied in industrial equipment applications where parts that can operate in the occupied environment against adverse conditions are produced accurately. Possibility to mix various materials with a certain set of properties can produce the result of products that have to serve demanding performance requirements with less maintenance and a long service life.

Advantages and Limitations

The benefit of insert molding is that there is a high structural integration capacity, dimensional stability, and the process facilitates complex assembly developments during one manufacturing cycle. The process can remove secondary assembly processes and possible failure points and then guarantee the accurate positioning of the embedded components.

Overmolding benefits include design flexibility, optimization of materials, production of features to already existing parts, and increasing the functionality of existing parts. Aesthetics, ergonomics and functional improvement can also be made without re-designing the entire commodity.

The drawbacks of insert molding are: limitation of compatibility of the materials, more complicated tooling, especially involving molded parts and expensive set up costs when it contains complicated shapes. Thermal sensitivity of the embedded components and the necessity to use special handling equipment may also act as a limitation of the process.

The restrictions of overmolding include the possible problem of delaminations in overmolded parts , the higher cost of material, and the more complicated quality-control policy. It is also possible that this process, especially when using a second mold, is limited in the parameter attainable wall thickness ratios and geometry around material interface insert molding process.

Choosing the Right Process

Technical requirements, cost considerations and expectations regarding the production volume have to be weighed against each other when it comes to process selection criteria in order to establish the most appropriate manufacturing strategy. Inserting injection molding is generally beneficial in high volume productions where structural integration and component positioning are of importance in injection molding machines.

Process selection decisions are often based on a technical requirement such as combination of properties of materials (i.e., strength, corrosion resistance), resistance to the environment, and the need to integrate functional parts. Applications that demand hermetic packaging, electrical conductivity or strength support might prefer one process to the other depending on the particular performance demands of threaded inserts.

Significantly depending on process economics are production volume thresholds, it is not at all uncommon that insert molding becomes much more economical with large production volumes as it can be automated and less labor is required. Overmolding flexibility and reduced tooling cost may be a benefit to lower volume application double injection molding.

The nature of products that will require short cycles in their development or frequent change in requirements (decision dependent) may lead to market considerations affected to the process selection. The overmolding frequently is faster than the insert molding applications with the prototype development and design iteration plastic mold.

Future Trends and Innovations

New technologies in multi-material production keep on expanding both insert molding and overmolding processes. The innovation within the two categories of techniques is being facilitated by advanced, better-performing processing equipment and automation systems molding plastic cost savings.

The concept of sustainability also partakes in process creation in the last few years, and the focus is placed on recyclable combinations of materials, the minimization of waste products and energy-cheap production processes complex two shot mold. These environmental realities are causing the research of bio based materials and closed-loop manufacturing systems two shot injection molding.

The adoption of digital manufacturing with Industry 4.0 technology is allowing real time monitoring of processes, predictive maintenance and adaptive control systems to increase the consistency of quality and efficiency of production two shot process overmolded material mold cavity. Such new technologies are opening up both processes to smaller manufacturers, and to more specific applications of plastic materials.

Integration of Additive manufacturing is a new trend that integrates conventional injection molding technology with a 3-dimensional printing platform into a hybrid manufacturing system of metal parts. Such combined methods present the opportunity to achieve customization and small-run production and also provide all the benefits of the proven molding methods cnc machining dash panels.

Заключение

The solution to the injection molding process of insert molding or overmolding phenomenon eventually belongs to a certain application specifics, the volume of production that has to be achieved, and economic prospects for softer plastic. Insert molding works well on the product producing integrating structure and large volume productions and overmolding is more flexible to use in product improvement and less quantity specific applications. The knowledge of the basic differences, strengths, and weaknesses regarding each of the processes is what facilitates the manufacturer to make intelligent decisions hence balancing the product performance and the economics of its production typically metal.