Description: Knit Lines in Injection Molding (Causes, Prevention, Quality control, and Solutions to knit lines, including how the parting line influences the proces .) Full reference manual on how to find defect free plastic components to manufacturers and engineers.

Knit lines are among the toughest imperfections of injection molding production processes, which have an impact on not only the structural integrity also the aesthetic value of the plastic parts curved parting line. These are noticeable lines which develop when two or more flows of the molten plastic run together in the injection process and do not blend correctly. Knit lines are unknown by manufacturers, engineers as well as quality control officers in the plastic injection molding business injection molding process.

It can be a major flaw towards product quality as knit lines can cause vulnerabilities on the final product and can lead to eventual product failure or even imperfection that can make complex parts or products unusable according to the proposed use of such a product comprehensive parting line sealing surface. The technical nature of knit lines, their etiology, as well as the effective prevention and mitigation, are further discussed in this all-inclusive guide prevent knit lines.

What Are Knit Lines in Injection Molding

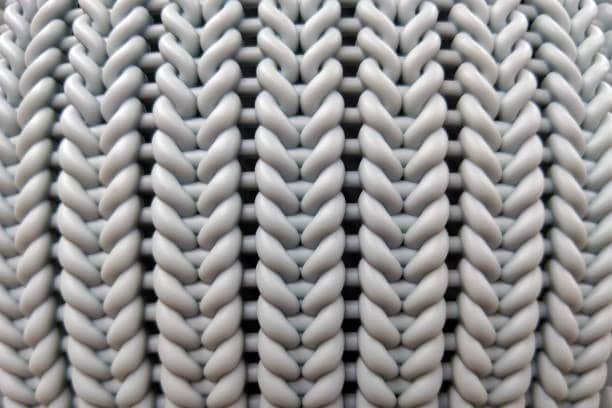

Weld lines or flow lines, also called knit lines, are those visible defects in injection-molded parts as thin line-looking or seams on the surface. Such lines come out when two or more streams of molten plastic material merge during the fill stage of the injection molding operation injection force. The meeting of the plastic flow with challenges like holes, insert or complex shapes results in the material breaking and reconnecting (convergence).

The inherent problem with the knit lines is that there is a non-complete molecular tussle of the grading flow fronts, particularly in a vertical parting line . At the intersection of the flows of molten plastic there should be a joint that is desirable to achieve on the molecular level as the result of its complete fusion and has a homogeneous structure. Nevertheless, this perfect bonding can be inhibited by numerous factors and the interface therefore remains weak by appearing with a discernible line and possibly undermined quality of the mechanical performances.

Unlike other injection molding defects, knit lines are the defects that are directly linked to the flow of the molten material, especially in cases involving a beveled parting line . Contrarily to sink marks or warpage, which can be discussed as cooling-related related problems, knit lines actually represent a flow-related problem, and thus take place in the filling phase of the molding process.

Understanding the Formation Process of Knit Lines

The establishment of knit lines occurs in a similar predictive pattern, concerning plastic flow behavior with injection molding. The molten plastic seeks the route of low resistance once it is injected inside the mold cavity and it will flow around the obstruction and through different cross-sections. The flow front is then divided into several flows as the material enters inlets, holes, pins or other complex geometric shapes.

These different streams go further into the mold cavity, flowing in different channels and at the end of the cavity combine again at the outlet downstream of the obstacle. The spot at which these flow fronts converge in turn gives the position of knit line formation. The quality of the fusion in this convergence point relies on some very important elements such as temperature, pressure, the rate of flow, and the direction in which the chains of the plastic are oriented.

These different streams go further into the mold cavity, flowing in different channels and at the end of the cavity combine again at the outlet downstream of the obstacle. The spot at which these flow fronts converge in turn gives the position of knit line formation. The quality of the fusion in this convergence point relies on some very important elements such as temperature, pressure, the rate of flow, and the direction in which the chains of the plastic are oriented.

Primary Causes Behind Knit Line parting line

Formation

Knit line formation in injection molding could be due to a variety of factors, and material related ones happen to be one of the most important. An important factor is the viscosity of the molten plastic because with increased viscosity materials due to the resulting loss of flow mobility at the convergence points, knit lines become more likely. Temperature sensitivity is also referred in the ability of various grades of plastics to fuse appropriately during the meeting of flow fronts.

Another significant group of causes of the knit line is its processing parameters. An under a pressurized injection may not sufficiently pack the material at the places of convergence and an under heated melting temperature too may undermine the capacity of the material to get molecular entangled. Speed of injection also applies in knit line formation where too slow and too fast speed may lead to the vice.

A consideration with regard to mold design, particularly the mold opening direction, has a substantial effect upon the presence of knit lines. The positioning of gates can be poor to produce undesirable flow patterns thereby promoting the possibility of knit line occurrence. Proper fusion may not take place where there is a lack of venting to trap air at points of convergence. Also, flow disturbances that cause the appearance of knit lines may be caused by wall thickness differences and abrupt changes in part geometry.

Material Factors Influencing Knit Line Susceptibility vertical parting line

Depending upon their molecular structure and their processing properties, different plastic materials may have a different level of vulnerability to knit line formation. Complex molecular structure plastics of high molecular weight, like some engineering plastics are more subject to knit lines based on lower mobility of the flow of the plastic and long chain entanglement times within the plastic.

Plastics in crystalline form possess special complexities in that there has to be scaling up of the molecular chains to the level of obtaining correct orientation and entanglement as they retain the capacity to form a clear substance in a homogeneous relationship. Semi-crystalline materials such as polyethylene and polypropylene have the potential to produce highly visible knit lines, especially in corners, because of changes in crystallization behaviour at the convergence zone as compared to the rest of material.

In plastic compounds, additives and fillers could play remarkable roles in the formation of knit lines. Molecular entanglement at converging points of flow fronts can be interfered with by glass fibers, mineral filler and colorants. The aspect and concentration of such additives determine the strength and the visibility of the knit lines that result. Certain additives can, in fact, assure that the knit line is reduced because of better flow characteristics or better fusion.

Processing Parameters and Their Impact on Knit Lines curved parting line

The processing parameters during injection molding must be well optimized, taking into consideration the cost implications of knit line formation. The temperature of melting is also one of the most important parameters, where, in the case of an inappropriate temperature, the material is too rigid to become sufficiently fluid and thus cause molecular agility that would result in adequate fusion. Nevertheless, the high temperature may also result in the degradation of the material and other quality features, and the reasonable approach is required.

The pressure in injection and rate of injection is combined to control the way well material moves and vises at merge points. Resistance to flow may be overcome by increasing injection pressures, which will also increase packing density at the knit line location. There is, however, a risk of creating other defects such as flash or part distortion resulting in excessive pressure. The speed of injections influences temperature distribution of the advancing flow front, where greater speed assists in sustaining higher temperatures at converging front.

Pressure and time parameters also have a great influence on the section of knit line because they define the quality of consolidation of the material, which occurs after the first filling. Good hold pressure will guarantee sufficient packing at convergence points during cooling and shrinkage of the part. Application of hold pressure should be done at the right time taking into consideration the specificity of the object that is being processed.

Mold Design Strategies for Knit Line Prevention

Successful mold design is the most proactive to the prevention of knit lines. Design and location of gates are the key variables that affect the flows and predisposition to knit line occurrence. Positioning of the gate strategically can reduce the numbers of convergence points or position them in non-relevant places of the part. Various gating techniques will assist in equalizing flow fronts and can minimize severity of knit lines.

The design of the runner system to flow balancing will help to make different sections of the part access the material at the same time thereby minimizing the temperature variance in the convergent flow fronts. It uses properly sized runners and gates that help to keep the material temperature and pressure during the filling process. Hot runner systems may be especially successful in terms of controlling the temperature of materials and minimizing knit lines.

Venting design O the venting design contribute significantly to the prevention of knit lines as it provides an opportunity to vent accumulated air in the convergence zones. Venting is also done to avoid entrapment of the air which could cause hindrance in molecular bonding at meeting points of flow fronts. Placements of vents should also be reviewed keenly to make them effective and not risking on the quality of parts and even the formation of a flash.

Quality Control Methods for Knit Line Detection

Knit line detection has been mainly visual as visual inspection is already the most common method to identify such defects as the lines on the faces of parts. Knit lines can be identified by the trained inspectors according to the characteristic look and position concerning the part geometry. Visual is, however, limited especially when detecting knit lines below the surface or knit lines at places where the surface texture is complex.

Scientific methods of inspection offer better knit line detection services. Internal knit lines, though not easily observable on the surface, can be tracked down with the help of ultrasonic testing; these are sites of structural weakness. Another item of non-destructive means of detecting internal discontinuity linked with knit lines is X-ray inspection.

Mechanical testing offers quantitative evaluations of knit line effects to part performance. Mechanical properties of molded parts may be monitored through tensile test, impact test, and fatigue test so as to understand the influence of knit lines on it. These tests especially matter to those parts which would undergo mechanical load throughout their service period.

Advanced Prevention Techniques and Technologies

Innovative injection molding technologies present intelligent methods of avoiding knit lines. A decrease in knit line formation can be achieved with gas-assisted injection molding especially in areas that pressure and temperature is maintained in thick-walled regions where knit lines tend to form. In this technology, pressurized gas is utilized so as to compact material in a better way and ensure mobility of compounds during cooling.

Multi zone temperature control systems make it possible to control temperature of materials within the flow path very precisely. These systems are able to enhance the molecular entanglement by keeping ideal temperatures at points of important convergence resulting to reduced knit line visibility. Advanced temperature control also allows control of the cooling rate differential between convergent flow fronts.

Knit line prediction and prevention has been revolutionized with use of simulation software. Knit line locations and severity may be predicted prior to mold construction with modern moldflow analysis tools. The simulations help install engineers to minimize knit line formation by optimizing the location, design and processing parameters of gates and runner. Virtual testing minimizes application of expensive trial-and-error method in eliminating the knit line.

Troubleshooting Common Knit Line Problems

Organised methods of problem solving will assist in locating and tackling knit line difficulties. The initial control is to record the position, occurrence and severity of knit lines in relation to the geometry of parts and processing parameters. This record assists in defining the patterns that could be used to direct the corrective measures.

Optimization of a process commonly starts with manipulation of temperature and pressure, since they have the most direct effect on molecular intersedation at fusion points. Silent incremental adjustments to melt temperature, injection pressure and hold pressure can frequently achieve a reduction in severity of knit lines and not necessitate adjustment of the mold. Nevertheless, such modifications have to be put against other quality needs.

In situations where parameter adjustments are still not enough, the mold might need adjustments. Essential flow based causes of knit line formation can be resolved by gate relocation, venting and/or runner system alterations. The changes also need thorough examination so that they do not originate other molding problems.

Industry Best Practices for Knit Line Management

Knit line management is a systematic process that should start with consideration on the design of parts. Knit line avoidance principles should be considered as the part of the design of manufacturability as: the fewest flow obstructions, alternative part geometry to reduce convergence points. Knit line problems can be avoided by conducting early design and production teamwork to eliminate such problems.

During knit line management, material selection is an important aspect. Knowing how all materials are affected by the knit line can assist us in selecting the material. Other applications might demand high quality materials with exceptional flow properties in order to develop acceptable knit line results. The material supplier can also come in to give good advice on processing suggestions to the material depending on the grades stepped shape.

Institutional knowledge about preventing and resolving knit line can be developed using documentation and knowledge sharing inside organizations, alongside the implementation of secondary operations to mitigate issue . Having data of previous solutions that are effective in a particular geometry part and material becomes a good source of future projects. The training programs make sure that the personnel is familiar with the basics of the knit line and prevention methods.

Заключение

Knit line control involves both technical and real-life know how of injection molding, where the parting line determines the quality of the final product two halves . With proper knowledge of the root causes and the effective prevention methods, manufacturers will be able to end up with high-quality parts that will meet both the functional and the aesthetic industries. The profits of investment in knit line prevention are high quality of goods produced, minimal rates of scrap, and high rates of customer satisfaction stepped parting line.