Meta Description: Learn all about cnc machining plastics, including material, processes, application and quality control, which are essential for various applications in numerous industries . See how the CNC technology revolutionises plastic production in terms of precision and efficiency.

There is a revolution in terms of manufacturing scene due to the introduction of the Computer Numerical Control (CNC) technology especially in machining plastics. This manufacturing process has transformed the manner in which industries previously produced plastic components and provides the level of accuracy, repeatability and efficiency that was previously unattainable, catering to specific needs . In cases of automotive parts, medical devices and so on, plastic CNC machining has proved a vital instrument of manufacturing high quality parts according to tight tolerances and very strict specification.

Contemporary business sectors are in need of manufacturing solutions which will prove to offer a consistent outcome and in a cost-effective manner. These demands are met by plastics CNC machining because it is highly technology-advanced and uses many plastics in a wide range of materials; hence innovative potential in several industries. Learning about the material properties, capabilities, applications, and best practices associated with this type of technology is important to business that wants to streamline its manufacturing operations.

Understanding CNC Machining for Plastics

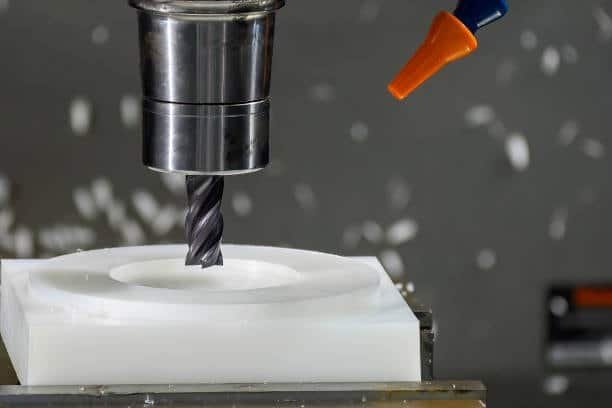

CNC machining is subtractive manufacturing, in which computer-aided instruments are used to extract materials in order to give a workpiece the required shape. This technology is distinctively beneficial when used to manufacture complex components from plastics for complex designs as compared to the traditional methods of manufacture. It starts with plastic block or sheet material and then accurately machined by cutting, drilling, milling, or turning to specified programmed dimensions.

CNC machining is computer controlled and this brings about extreme repeatability and accuracy which makes it better to manufacture complex hydromat parts with real close tolerances. Since it uses only inexpensive programming as opposed to costly tooling as in injection molding, CNC machining can accommodate quick-change designs or be ushered in with corrections valuable especially to prototyping and low to medium runs of the production cycle.

Types of Plastic Materials Suitable for CNC Machining

Utilization of different plastics is a key to effective CNC machining processes. We can have engineering plastics such as ABS (Acrylonitrile Butadiene Styrene) which are highly machinable with good impact resistance, high stiffness, and demonstrate acceptable dimensional stability. Because of its property profile and chemical resistance, this thermoplastic is commonly used in automotive, electronics and consumer goods.

Acrylic (PMMA) offers a very high level of optical clarity and weather resistance, which makes it ideal in a case which needs to be transparent or to look good. It has great machinability, which permits it to produce smooth finishing of surfaces and great control of dimensions. Polycarbonate has greater impact strength and temperature stability but needs to be machined with great consideration to parameters otherwise it will stress crack.

Polyamides such as nylon offer very good mechanical properties, such as high strength-to-weight ratio and do not dissolve easily. Nonetheless, such materials need a unique method of machining so as to control the tendency of creating heat when machining. PEEK (Polyetheretherketone) is the top of the range of engineering plastics with outstanding chemical resistance, high temperature capability and biocompatibility in extreme situations.

Essential CNC Machining Processes for Plastics

CNC milling is the core of plastic machining, where the tool used is rotating hence removing material to achieve sophisticated shapes. Face milling leaves flat faces, whereas end milling combination leaves slots and pockets and contours. The secret of success during plastic milling is to choose the right cutting speeds, the right cutting tools feed rates and tool geometries that should ensure minimum heat generated and no melting of materials.

The turning functions in CNC lathes produce cylindrical shapes, such as having external or internal diameters, threads and tapered surfaces. Plastic turning entails the use of sharp cutting legs and coolant application that ensures dimensional accuracy and the surface finish. Turning involves repeated cutting that has potential to produce a lot of heat, especially at elevated temperatures, and therefore thermal management is an essential aspect of ensuring efficient operations polyether ether ketone.

The action to drill a hole through plastics requires certain attention concerning the chip removal and hole quality. General twist drills can delaminate or even burr and special drill geometries best suited to plastic materials may be required. Good drilling allows induction of efficient, clean and precise holes not interfering the integrity of the material project requirements.

Advanced Tooling and Equipment Selection

The choice of tools is also an important factor in the plastic CNC machining processes influencing the quality and productivity. Carbide cutting tools are resistant to wear and facilitate sharp cutting edges compared to cutting tools made of high speed steels that do not maintain the cutting edge as long as the carbide ones do. Cutting tools used with plastic materials require an optimized geometry as they will normally have a sharper cutting edge as well as potentially a polished cutting edge to reduce the generation of heat due to friction.

Recent CNC plastic machining equipment is equipped with such features as fast rotation speeds, temperature regulation, and sophisticated coolant systems. Such machines are capable of holding the close tolerances necessary of precision plastic parts, taking into account specific material properties, whilst being as highly automated as possible, through optimized cut parameters and automated changeover of tools.

Plastic components need particular attention when it comes to workholding systems because of the deforming nature of such materials when stressed. The use of soft jaws, vacuum fixtures and also specialized techniques of clamping can help hold the part geometry as well as have sufficient holding ability whilst the machining is in progress.

Quality Control and Precision Standards

A plastic CNC machining process starts with quality inspection during incoming materials and stretches across all processes in the process. Coordinate measuring machines (CMM) allow dimensional accuracy checking of finished parts to assure that the parts are within specified tolerances. Any plastic components intended to be used in optical or aesthetic purposes have Statistical process control (SPC) methods aid the consistent quality by observing vital process factors and recognizing trends prior to the creation of flawed pieces. Calibration of measuring devices and service of CNC machines will guarantee further accuracy and reliability of these devices in production activities.

The monitoring of temperature during the machining process will assist in the prevention of thermal degradation in the plastic material. Most plastic parts have to be examined post machining to check any stress cracking especially at places where localised heating could have taken place during the machining process.

Industry Applications and Use Cases

Automobile manufacturers use plastic CNC machining in the production of interior trim parts, dashboard items and under-hood components that need exact placement and are subjected to the test of wear. The type of applications usually requires material that has the ability to retain dimensional stability under extreme temperatures and mechanical stress over long service periods, especially in demanding environments .

Another high use scenario of plastic CNC machining is in the manufacture of medical equipment where the requirements of the instruments, implants, and diagnostic devices used medically demand the accuracy and biocompatibility available through CNC machining of plastic. Complex geometries using medical grade materials and custom parts require the use of CNC technology as no other technology would allow the production of medical-grade parts quite as easily.

Electronic and Telecom sectors employ plastic CNC machining in producing housings, connectors and other body parts that offer electromagnetic shielding and environmental protection. CNC machining precision achieves appropriate fit and functionality in these key parts in intense electronic designs.

Design Considerations for Plastic CNC Parts

Effective plastic CNC machining starts with a well designed part that takes into consideration the individual properties of plastic materials and CNC machining. The uniformity of the wall thickness avoids warping and dilutions as a result of the machining process and the radii are very large which minimizes the stress concentration and offers greater tool life. Internal sharp corners should also be avoided because they necessitate special tooling, and could cause stress concentration points.

Although draft angles are not always required in CNC machined components, they aid in improving surface finish as well as alleviating tool wear in situations, where they are used in designing parts. The hole placement and size used are well considered in terms of the drilling capabilities as well as the sufficient material support in case of the machining operations.

DFM guidelines can be used to design the part, so that it can be very easily machined by CNC processes and can still perform its intended functions. This incorporates tool setup, fixture needs, as well as machining pattern to reduce the amount of time in setting up, and increase the amount of productivity.

Cost Optimization Strategies machined plastic

The choice of the material has a considerable influence on the total price of plastic CNC machining project. Although high performance engineering plastics have excellent properties, in many applications they can be gotten by using standard materials that would offer satisfactory performance at a low cost. Standard materials used should be bought in large quantities to get the unit price decreased and the material in application to be available in order to meet production deadlines.

Factors that can save significant amount of production cost are optimized cutting parameters, selection of suitable tools and nesting of parts in machine operations. Part loaders, machineries and unloaders are automated to reduce labor cost and enhance uniformity and flow of parts.

More cost can also be saved in the form of design optimization to allow lesser machining time with functionality of the part being maintained. The cost of manufacturing is reduced by the elimination of wasteful features, optimising part orientation and designing with standard tooling, which also minimizes the environmental impact .

cnc plastic machining

Surface Finishing Techniques

The plastic CNC parts can be substantially improved visually and through their performance by post-machining surface treatments. Mechanical polishing is used to produce smooth machined parts , reflective, optical or cosmetic surfaces. Roughing polishing Made with coarser abrasives and then polishing using progressively finer abrasives expel machining marks and tool signatures and thus progressively improve surface quality.

Extremely smooth surfaces may be attained on some plastics by means of chemical polishing with application of suitable solvents, but direct control is necessary to avoid dimensional effects or defects on surfaces. Vapor polishing is a sophisticated process which has the capacity to yield transparent plastics with optically transparent surface.

The application of texture by means of different methods makes it possible to customize the surface looks and feel. Surface patterns may produce a desired functional or aesthetic effect, either by functional (laser texturing, where arabesque textures can be produced by many lasers) or decorative chemical etching, or by mechanical texturing that may improve part performance or appearance..

Troubleshooting Common Machining Issues

The most frequent issue of plastic CNC machining is heat related issues. The elevated cutting temperatures may result in melting of the material, distortion of dimensions or a form of stress cracking, particularly in materials with lower wear resistance . It can be solved by slowing cutting speeds, enhancing coolant flow, sharper tooling, and focus feed rate to limit the amount of heat created.

Surface finish and dimensional inaccuracy caused by chatter and vibration difficulties may arise. These problems are avoided by proper workholding, choice of tools, and optimal cutting parameters. The maintenance of the machine, balancing the spindle also have a role to play in the reduction of vibration as well as the enhancement in the quality of the part

wide array.

Surface and dimensional changes, chip evacuation issues may lead to the breakage of tools and defects in the surface. Effective chip removal process in machining operations is achieved by properly breaking chips, the flow of adequate coolant, and proper geometry of the cutting tools.

Automation and Future Technologies

Plastic machining services by CNC have automated loading and unloading machines that enhance work rates at low labor costs. The parts can be dealt with by robotic systems continually and safely, especially since dangerous materials or high temperatures are involved, and materials with corrosion resistance are preferable . Real-time adjustments in mechanisms of machining are doable through its integration with quality control systems.

CNC operations plastic Adaptive machining technologies which continually fine-tune cutting parameters to real-time feedback promises to bring even greater efficiency and quality to plastic CNC operations. The systems have the ability to adjust and adhere to changes in the material, the wear of tools as well as the environment without the need of an operator.

The Fourth Industrial Revolution principles such as IoT connectivity, predictive maintenance, and data analysis are changing plastic CNC machining into a predictive instead of reactive manufacturing processes bead blasting. The technologies allow optimizing the overall equipment effectiveness and minimizing unplanned downtime and quality problems.

Environmental and Safety Considerations

Effective ventilation systems are also needed in plastic CNC machining in order to get rid of presumably harmful particulates and vapors that are produced as part of cutting procedures. Dust collection systems safeguard both the equipment and operators besides ensuring clean working environments. Material specific safety data sheets contain information on specific handling and disposal methods.

Waste management and recycling programs are more than feasible in reducing the consumption of plastics in plastic CNC machining activities. Several plastic machining chips and 90w waste products are recyclable or can be re-processed, but the issue of contamination is very important on the aspect of ensuring the quality of materials in the recycled processes cnc engraving.

One way of lowering the operating cost as well as the environmental burden of CNC machines is to take into consideration energy efficiency when selecting and using them. New machines have energy-saving characteristics such as lightweight standby models, spindle drive that is efficient, and optimized coolant that results in reduced power usage during the run certain plastics.

Logistics and Supply Chain Integration

Effective logistics and supply chain are very important in effective plastic CNC machining processes. Excellent raw materials supply can result in quality supply and predictable availability of raw materials within the plastic supply chain as inventory management will help to reduce carrying costs without jeopardizing the production flow electrical insulation.

Shenzhen Guanwutong international freight forwarding Company (GWT Worldwide) deals with the supply of full logistical services to manufacturing processes. GWT is a professionally established logistic service provider that provides air freight, sea freight service, China-Europe railway transportation as well as international express service. Their experience in custom clearance, warehouses and Amazon FBA shipping aid enhance the business streamline their supply chain practice and concentrate on core production processes.

The strategic alliances of those companies doing plastic CNC machining with logistical providers allow them to get into a full offering business model to their customers which extends beyond the supplying of raw material to providing the end part plastic type. The combined solution makes the process simpler and less expensive for all components as the level of services and customer satisfaction increase.

Заключение

The concept of plastic CNC machining is the high-tech advanced manufacturing technology which is provided with precision, flexibility, and efficiency that manufactures high-end plastic parts working in various industries. To conduct the successful work with plastic CNC machining, it is essential to pay attention to material selection, optimizations of the process, quality control, and cost management solutions. This technology still progresses and opens new features: automotive, medical applications; electronics, consumer products.