Swiss Machining: The Ultimate Guide to High-Precision Manufacturing Excellence

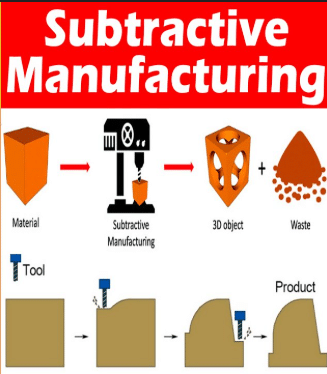

Swiss machining is an excellently developed precision manufacturing technology that can never be matched in terms of accuracy and efficiency in the manufacture of complex components. The technology originated in Swiss watchmaking and is still a must in such industries as aerospace and automobile industries that need manufacturing with a high level of precision and quality.