The Evolution of Manufacturing Precision

The manufacturing landscape has undergone remarkable transformation since the introduction of Computer Numerical Control (CNC) technology, particularly in cnc precision machining processes . What once required skilled machinists performing manual operations has evolved into sophisticated automated processes capable of producing components with microscopic precision. CNC precision machining represents the pinnacle of modern manufacturing technology, combining advanced computer programming with highly engineered machine tools to create parts that meet the most demanding specifications.

Understanding CNC Precision Machining Fundamentals

CNC precision machining utilizes computer-controlled machines to remove material from a workpiece to create a desired shape or component. These machining processes interpret digital instructions, converting design specifications into precise tool movements. The beauty of CNC technology lies in its ability to repeat complex operations with consistent accuracy, eliminating human error and producing identical parts with micrometer-level precision.

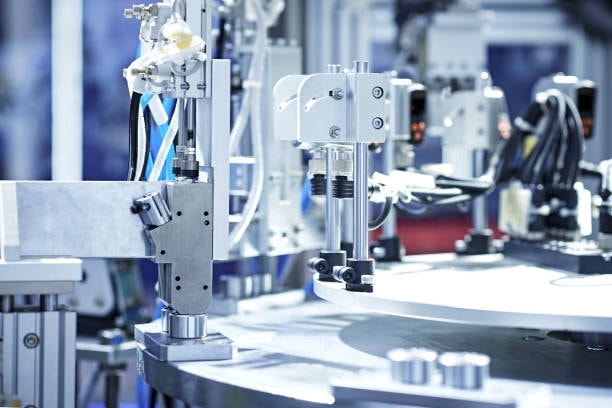

Key Components of CNC Machining Systems

Modern CNC systems consist of several integrated components working in harmony, showcasing advanced technology . The control unit serves as the brain, interpreting programmed commands and directing machine operations. Servo motors and drive mechanisms translate digital signals into physical movement. Cutting tools perform the actual material removal, while workholding fixtures secure materials during processing. Measurement and feedback systems continuously monitor operations, ensuring dimensional accuracy throughout production.

The Programming Behind Precision

At the heart of CNC precision machining lies the programming language that controls machine movements. G-code remains the industry standard, containing specific instructions for tool paths, feed rates, spindle speeds, and tool changes. Modern CAM (Computer-Aided Manufacturing) software has simplified programming, allowing operators to generate complex tool paths from CAD models automatically. This technological advancement has opened doors for creating increasingly complex components while reducing programming time.

Materials Mastery in CNC Machining

CNC precision machining demonstrates remarkable versatility across materials, utilizing various precision machining techniques . From aluminum and steel to exotic alloys like titanium and Inconel, CNC processes can be optimized for specific material properties. Plastics, composites, and even wood can be precisely machined using appropriate tooling and parameters. This material flexibility makes CNC machining indispensable across diverse industries requiring precision machined parts and specialized components.

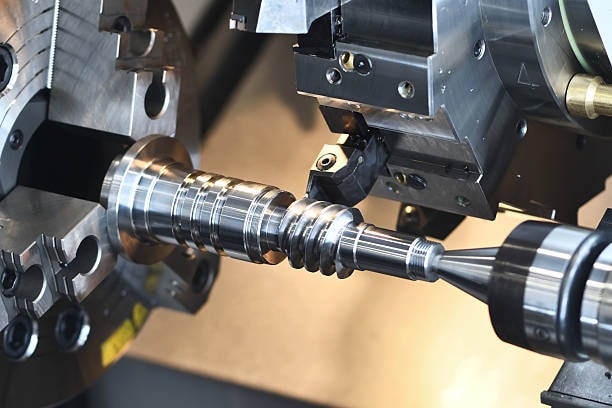

Achieving Micron-Level Tolerances

The hallmark of high precision machining is its ability to maintain extraordinarily tight tolerances. High-end CNC machines can routinely achieve tolerances of ±0.0005 inches (0.0127mm) or better. This level of precision enables the production of critical components for aerospace, medical devices, and precision instruments where even microscopic deviations could compromise performance or safety.

Surface Finish Excellence in Precision Machining

Beyond dimensional accuracy, surface finish quality distinguishes exceptional CNC machining from conventional machining methods . Modern CNC processes can produce mirror-like finishes with roughness values measured in microinches. This capability eliminates secondary finishing operations in many applications, reducing production time and costs while enhancing component performance and aesthetics.

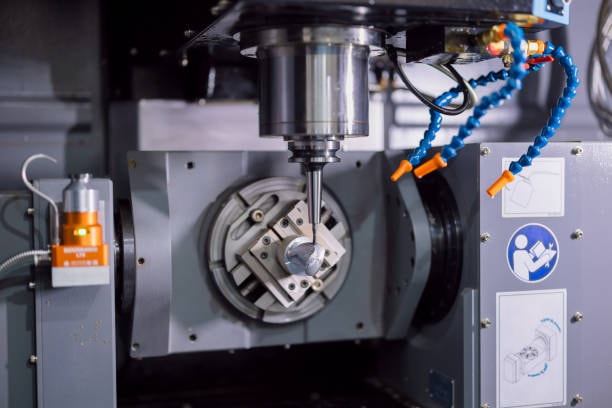

The Role of Multi-Axis Machining

Advancements in CNC technology have introduced multi-axis machining capabilities that extend beyond traditional 3-axis systems, particularly in cnc machine shops . 5-axis machines can approach workpieces from virtually any angle, enabling the creation of complex geometries in a single setup. This capability reduces handling time, improves accuracy, and allows for machining features that would be impossible with conventional 3-axis approaches.

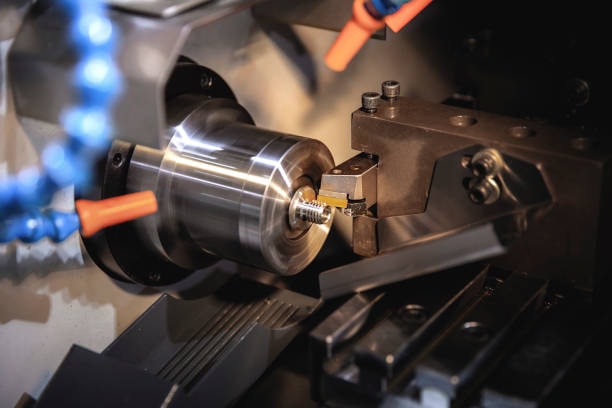

Precision Turning Operations

Advancements in CNC technology have introduced multi-axis machining capabilities that extend beyond traditional 3-axis systems. 5-axis machines can approach workpieces from virtually any angle, enabling the creation of complex geometries in a single setup. This capability reduces handling time, improves accuracy, and allows for machining features that would be impossible with conventional 3-axis approaches.

Advanced Milling Techniques

CNC milling represents another cornerstone of precision machining. High-speed machining centers can remove material at accelerated rates while maintaining dimensional integrity. Techniques like trochoidal milling create complex pockets with reduced tool loads, extending tool life and improving surface finish. Ball-nose end mills produce smooth contoured surfaces essential for mold and die applications.

The Precision of Wire EDM Technology

Wire Electrical Discharge Machining (EDM) and spark machining represents an ultra-precise CNC process capable of cutting hardened materials with exceptional accuracy. Using an electrically charged wire, this technology can achieve tolerances within 0.0001 inches while creating intricate profiles in tool steels and other challenging materials. Wire EDM excels at producing machined parts, precision tooling components, and medical devices where extreme accuracy is non-negotiable.

Laser and Waterjet Precision Cutting

Beyond traditional material removal methods, CNC precision extends to advanced cutting technologies, including cnc plasma cutters . Laser cutting systems offer exceptional edge quality and positional accuracy for sheet materials, while waterjet cutting provides similar precision without thermal effects. These non-contact methods excel at creating complex profiles in materials ranging from paper-thin foils to thick steel plate, complementing traditional machining capabilities.

Quality Assurance in Precision Manufacturing

Quality control represents an essential element in CNC precision machining operations, including effective cnc programming . Coordinate Measuring Machines (CMMs) verify dimensional accuracy against digital models, while optical measurement systems inspect surface characteristics. In-process probing increasingly allows for real-time verification and automatic compensation, ensuring components meet specifications before leaving the machine.

Industry Applications of CNC Precision Machining

Aerospace Components

The aerospace industry demands the ultimate in precision machining, particularly for parts like turbine blades . Engine components, structural elements, and flight control systems require exceptional dimensional accuracy and surface integrity. CNC precision machining delivers complex parts and geometries in exotic materials while maintaining the exacting tolerances required for flight-critical applications.

Medical Device Manufacturing

Medical implants and surgical instruments represent another domain where precision machining proves invaluable. CNC processes create orthopedic implants with complex surfaces that promote osseointegration, dental components with microscopic features, and surgical instruments with exceptional ergonomics and functionality. The biocompatibility of machined surfaces directly impacts patient outcomes.

Automotive Precision Components

Modern vehicles incorporate numerous precision-machined components, supported by precision cnc machining services, that enhance performance and efficiency. From engine blocks and cylinder heads to transmission components and fuel system parts, CNC machining ensures dimensional consistency across high-volume production runs. This consistency translates to improved engine efficiency, reduced emissions, and enhanced reliability.

Optics and Photonics Manufacturing

The optics industry leverages CNC precision for creating lens mounts, optical benches, and instrument housings requiring exceptional flatness and positional accuracy. Diamond turning, a specialized CNC process, can produce optical surfaces with accuracy measured in nanometers, enabling advanced imaging systems and scientific instruments.

Electronics and Semiconductor Equipment

Semiconductor manufacturing equipment incorporates precision-machined components that position wafers with nanometer accuracy. CNC machining creates complex cooling channels, precision stages, and structural components that enable the production of increasingly powerful and miniaturized electronic devices.

Economic Considerations in Precision Machining

While CNC precision machining delivers exceptional quality, economic factors influence manufacturing decisions. Material costs, programming time, machining cycle time, and tool wear all contribute to component pricing. Balancing precision requirements against production costs requires experienced engineering judgment. For high-volume applications, the initial investment in tooling and programming can be amortized across production runs, making precision machining economically viable even for competitive markets computer controlled machine tools.

Sustainable Aspects of Modern CNC Operations

Modern CNC machining operations increasingly emphasize sustainability, implementing high velocity machining processes to maximize efficienc . Minimum quantity lubrication (MQL) systems reduce coolant consumption while maintaining tool life. Energy-efficient machines incorporate regenerative drives and optimized motion control to reduce power consumption. Advanced tooling maximizes material removal rates while extending tool life. These innovations reduce the environmental footprint of precision manufacturing without compromising quality.

The Human Element in Automated Precision

Despite increasing automation, skilled technicians and machine operators remain essential to CNC precision machining cnc operator. Experienced programmers utilize various machining techniques to optimize tool paths for efficiency and quality. Setup technicians establish robust workholding and tool offset parameters. Quality specialists interpret measurement data and implement process improvements. This human expertise ensures CNC systems deliver their full potential in challenging applications cnc equipment.

Emerging Trends in CNC Precision Technology

The future of CNC precision machining encompasses several emerging technologies, including cnc turning . Artificial intelligence increasingly optimizes cutting parameters based on real-time feedback. Digital twins simulate machining operations before cutting material, preventing costly errors. Hybrid manufacturing combines additive and subtractive processes within a single machine, enabling previously impossible geometries. These innovations continue expanding the boundaries of what precision machining can accomplish rotating cutting tool.

Selecting a Precision Machining Partner

Organizations seeking precision-machined components should evaluate potential manufacturing partners carefully. Technical capabilities, quality certifications, and industry experience provide meaningful selection criteria. Equally important are communication systems, project management approaches, and continuous improvement methodologies. The right precision machining partner delivers not just components but comprehensive manufacturing solutions.

Integration with Digital Manufacturing Ecosystems

Modern CNC precision machining increasingly integrates into broader digital manufacturing ecosystems. ERP systems manage material flow and production scheduling. MES platforms track real-time machine utilization and part quality. Cloud-based collaboration tools connect designers with manufacturing engineers, accelerating product development cycles. This digital integration enhances both efficiency and quality in the overall manufacturing process of precision machining operations cnc precision milling.

Overcoming Precision Machining Challenges

Achieving exceptional precision involves overcoming significant technical challenges. Thermal expansion during machining can cause dimensional variations requiring compensation strategies. Vibration during cutting operations can compromise surface finish, necessitating specialized tooling or machining parameters. Material variations may require adaptive control systems to maintain consistent results. Addressing these challenges requires both technical expertise and practical experience cnc precision machining services.

บทสรุป

CNC precision machining continues revolutionizing manufacturing across industries, often outperforming conventional machining in demanding exceptional accuracy and surface quality. The integration of advanced computer control with precision mechanical systems enables the production of components that would be impossible to create manually cnc milling machines. As manufacturing technologies evolve, CNC precision machining remains foundational to creating the complex, high-performance components that drive innovation across industries from aerospace to medical devices. The future promises even greater precision, efficiency, and capability as digital technologies and machine tool advancements continue their rapid evolution.