Meta Description: Find out general types of welding defects that occur in welding, the welding defect causes and effective solutions. Find out how to recognize, avoid and correct such common weld defects as porosity, cracks, undercutting, insufficient fusion in the weld joint . A guide to welders and professionals in the area of quality control.

Welding is one of the important processes used during manufacturing where any metal component is joined in a permanent affix as a joint but ideal welding cannot be done at every instance without knowledge on how to avoid various different welding defects likely to affect the structural integrity. Poor welds lead to internal welding defects and leave the joints beyond tolerable limits, something that makes the identification and prevention of the welding defects an important skill to any welding expert.

Understanding Welding Defects vs. Discontinuities

The definition of defects welding and discontinuities is considered essential to the quality management of welding operations. Weld discontinuity is an interruption of normal flow of weld bead metal structure in weldment and defect is a situation where more than allowable weld discontinuities exist as specified by codes or specifications applicable.

Critical Importance of Defect Prevention

Defects of welding may result into a disaster in building, equipment and machinery. Their causes should be understood and adequate prevention measures put in place to ensure that industry, including construction and aerospace manufacturing among others, is safe from any external welding defects and where defect occurs. and its products reliable.

Classification of Welding Defects

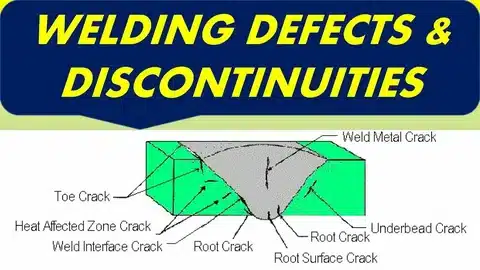

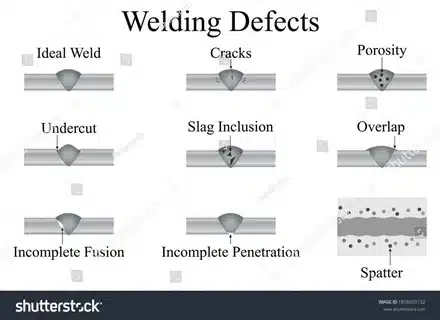

Internal vs. External Defects

Internal defects arise in the weld metal, and they are not observable without the help of visual inspection. The latter can be identified using traces of highly sophisticated non-destructive tests, including radiographic or ultrasonic tests. The external defects are not embedded deep into the weld surface material and they are readily distinguished by sight or the techniques of observation of the surface using correct welding technique .

Volumetric vs. Planar Defects

Volumetric defects are space occupying imperfections in three-dimensional space inside the weld metal e.g. porosity and inclusions. Two-dimensional planar defects are those defects that occur in a single plane such as cracks and zones of lack of fusion in the molten metal .

Structural Impact Assessment

The degree of welding defects is identified by its type, size, position and orientation to stress concentrations. The knowledge of such factors assists in establishing that a defect in the weld bead entails an urgent repair or can be tolerated.

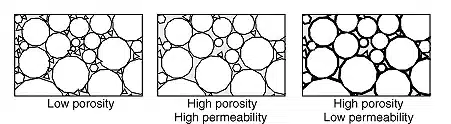

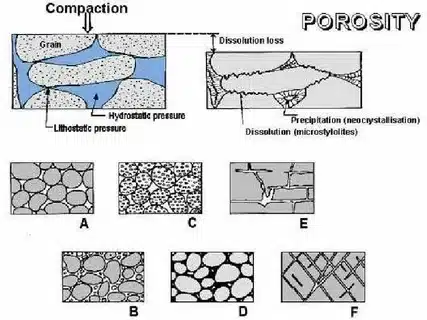

Porosity: Gas Entrapment Issues

Understanding Porosity Formation

One of the most frequent welding defects, including welding cracks, is called porosity, and it emerges when gases are trapped throughout the solidification of the substance. They cause low-strength areas in the weld zone, including surface porosity, and may greatly lower the strength of the joints when in service.

Types of Porosity Defects

Linear porosity involves a series of the gas pores being perpendicular to the weld axis as a parallel line whereas localized porosity appears as a cluster of the pores. Porosity occurs on the surface of the weld and the porosity is also distributed evenly at random.

Root Causes of Porosity

Inadequate amount of shielding gas flow permits contamination in the atmosphere whereas excessive amount of the shielding gas provokes turbulence and may be due to incorrect welding parameters causing some air to be present in the weld pool. The causes of porosity also include incorrect welding patterns, contaminated base materials, inappropriate storage of electrode as well as ineffective preparation of joint.

Porosity Prevention Strategies

The solution to avoiding porosity is to maintain good shielding gases flow rates, clean base material and well-stored electrodes, including appropriate welding wire . Good joint preparation involving oil, paint and rust removal presents a great limitation to risks to gas entrapment when using proper welding technique .

Porosity Repair Methods

Isolated porosity may be fairly easily fixed by grinding out the defect and re-welding. Wide-spread porosity, crater cracks, and incomplete fusion may need total removal and re-welding of the concerned segment with better welding parameters and preparation methods.

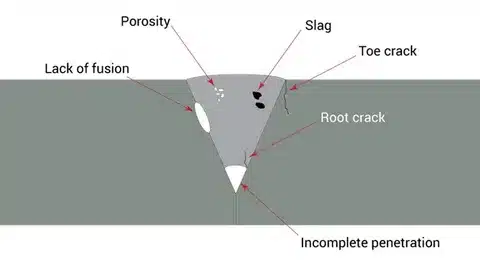

Cracks: The Most Serious Defect

Crack Formation Mechanisms

The most severe welding defects are welding cracks since they tend to spread under stress culminating into a disastrous failure. They occur either as a result of metallurgical changes, thermal strains or incorrect welding angle during welding and cooling after process, contributing to lack of fusion .

Hot Cracking vs. Cold Cracking

Hot cracks form during solidification processes at high temperature; usually at grain boundaries. The cold cracks are formed during the cooling at a fast welding speed , they will be frequently hydrogen-formed, and may show up hours or days following the completion of the welding process.

Longitudinal Crack Characteristics

Longitudinal cracks are in direction of weld axis, normally occurring due to over restraint, poor design of joints or due to wrong electrode angle in the welding process. These cracks have a major tendency of decreasing the load bearing capacity of welded joints to the greatest extent.

Transverse Crack Formation

Transverse cracks are cracks which go across the weld in a direction perpendicular to the direction of the welding job. They normally occur because of the high residual stresses, high welding speed or metallurgical reasons in the heat affected zone.

Crater Crack Prevention

One of the types of crack is crater cracks which occurs at the weld termination area and this type of crack can be avoided by using good terminations of the arcs such as crater filling method and by using controlled current decline.

Crack Repair Procedures

Repair of crack involves the entire crack material removal to be removed at the weld toe , preheat whenever needed and redone through proper procedures of welding. Severe applications may have to undergo stress relief procedures.

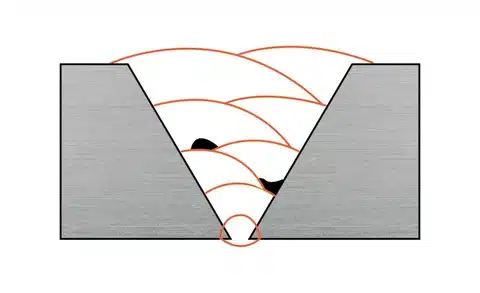

Lack of Fusion Defects

Root Fusion Problems

Lack of root fusion: This situation is observed when the weld metal does not completely fuse with the base metal at weld root. This forms a vulnerable area which can not withstand a comparative strain when inadequate filler metal is used .

Sidewall Fusion Issues

The sidewall fusion issues occur in a condition where the metal does not fuse well with the base metal on the sidewalls of the joints. This normally occurs due to inadequate heat or due to inappropriate handling of electrodes and poor interaction with the parent metal .

Inter-run Fusion Defects

In multi-pass welds, there is absence of inter-run fusion amongst successive layers of weld. This crack affects the integrity of the joint structurally as well as it lowers the strength of the weld.

Fusion Defect Causes

Poor welding current, too high travel speed and improper electrode angles are some of the causative factors of fusion problems. Dirty surfaces as well as improper preparation of joints, and wire feed speed along with improper methods of welding also contribute immensely.

Fusion Improvement Techniques

Fusion quality can be increased by increasing welding current, slowing travel speed and better control of electrode diameter manipulation. Fusion-related faults are avoided by means of adequate joint preparation for a fillet weld and cleanup between applications.

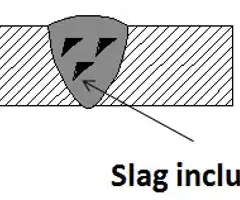

Inclusions: Foreign Matter Contamination

Slag Inclusion Formation

Slag inclusions are found when flux substances get entangled into the liquid weld metal before getting hard. Such non metallic inclusions, including improperly used filler metal, establish weak areas and may start to crack-up under stress.

Tungsten Inclusions

In a TIG welding tungsten inclusions are caused by electrode contamination or poor casting technique. These massive metallic inclusions are evident on radiographic forms as bright spots and have to be eliminated.

Oxide Inclusion Problems

Oxide inclusion comes about when the oxides of the base metal are not cleared properly in the process of welding. Such slag inclusions may considerably decrease fields of weld ductility and toughness.

Inclusion Prevention Methods

Most of the inclusion defects are avoided by doing proper inter-pass cleaning, stick welding proper welding parameters, and sufficient shielding gas coverage. It is also aid by proper welding procedures and clean electrodes.

Inclusion Removal Techniques

The majority of inclusions have to be removed by grinding or machining and re-welding. It is important to have complete removal to avoid focus of stress and possible start of failure.

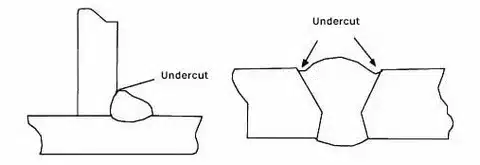

Undercutting Defects

Undercut Formation Mechanisms

Undercut produces shallow notch in the base material next to the weld joint toe that thins the effective cross section and leaves stress concentration points potentially resulting in fatigue.

Welding Parameter Effects

Undercutting is caused by excessive current in the welding operation, excessive travel speed and incorrectly positioned angles of the electrode. Undercut formation also greatly depends on the arc length and the welding technique.

Undercut Prevention Strategies

They can be avoided by reducing welding current, travelling speed and ensuring correct electrode angles. This imperfection is also reduced by the use of proper weaving methods and wrong welding technique manipulation of the arcs.

Undercut Repair Methods

Minor undercutting may be restored by adding more weld metal into the under penetrate. Severe under cutting can necessitate grinding and the re-welding of the section completely.

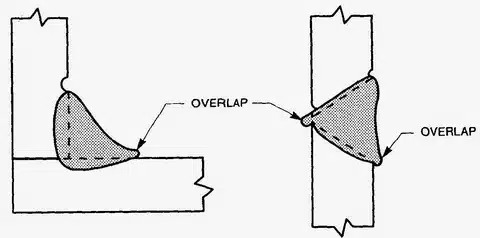

Overlap and Over-roll Defects

Overlap Formation Process

Overlap When weld metal flows across the base metal and there is no proper fusion. This causes stress concentration and possible corrosion point that weaken joint integrity.

Over-roll Characteristics

Over-roll is a weld metal deposition too large to provide a smooth weld profile. It may not be structurally critical, but could also impact the aesthetic appearance of the joints and may need to be corrected because of their appearance.

Overlap Prevention Techniques

Overlaps are avoided by ensuring that the travel speed is correct, and that the angles in the electrode are correct, and that the controlled heat source is providing the appropriate amount of heat. Welding technique when done properly and constant manipulation gives uniform weld profiles.

Overlap Repair Procedures

The repair of overlaps normally includes grinding off the uncatching of the material and re-welding the weld deposit in case of need. Proper joint geometry and stress distribution can be achieved by complete elimination of overlapped area and maintaining the correct welding speed .

Excess Penetration Issues

Penetration Control Factors

The problem of excess penetration arises when more weld metal comes out of the root area of the joint than is desirable thus resulting in irregular geometry and possible stress concentrations at the metal surface and backside of the joint.

Root Opening Considerations

Poor dimensioning of root opening, high welding current and low travel speeds add to the over penetration. The quality of joint fit-up and the correct arc length also have a great impact on penetration control.

Penetration Prevention Methods

Excess penetration can be avoided by controlling welding current, the proper travel speed, and joint fit-up. It also helps using supporting materials or using the correct dimensions in opening roots while maintaining proper arc length .

Penetration Correction Techniques

Over penetration correction could involve grinding of the back portion of the joint to get the right geometry. Owners In other instances there has to be total re welding with better parameters.

Burn-through Defects

Burn-through Formation

Burn-through, sometimes known as punching or drilling, is a result of excessive heat, in thin parts, or upon welding parameters being too aggressive in a part whose thickness is overmatched by the welding parameters used.

Material Thickness Considerations

Materials so thinned are especially susceptible of burn-through, and close control of the heat input and manufacturing technique of the welding is needed. Fit-up and design in joint become important issues in prevention.

Burn-through Prevention

Burn-through can be prevented by reducing welding current, increasing travel speed and following the suitable techniques of welding. This is also safeguarded by the proper preparation and back up materials of joints.

Burn-through Repair Methods

Burn-through repairs are normally repaired by patching or redoing the whole joint preparation and welding. The method of repair is based on the size and place of the defect.

Incomplete Joint Penetration

Penetration Requirements

Incomplete joint penetration refers to the condition in which the weld does not weld entirely through the joint thickness resulting in areas that are unwelded and blow holes capable of localizing stress that may decrease performance of the joint.

Joint Design Impact

Poorly designed joints, underdesigned root opening or oversized root face dimensions may also cause incomplete penetration. Structured joint geometry is vital in full penetration.

Penetration Enhancement

Welding current can be increased, travel speed reduced and joint preparation improved, to increase penetration. Use of fitting electrodes and technique of welding also helps in total penetration.

Penetration Repair Strategies

Back-gouging and reverse side welding is frequently necessitated by incomplete penetration repair. Critical applications may require a full re-welding, and joint preparation.

Spatter and Arc Strikes

Spatter Formation Causes

Spatter can be described as the molten movement of metal particles that may escape the weld pool possibly causing alterations of the surfaces and polluted content. Overcurrent and inadequate shielding gas may cause the spatter to be more likely to be formed.

Arc Strike Damage

Because of arc strikes, a localized heating and possible metallurgical changes can occur in the base metal out of the planned range of welding. These may cause stress risers and alter properties of the material.

Spatter Prevention Methods

Observation of good welding parameters, avoidance of undesirable shielding gas composition, and clean base material assists in minimising spatter during welding.

Spatter Removal Techniques

Removal of spatter is usually by mechanical means such as grinding, or by wire brushing. Total amputation should be done as a way of avoiding corrosion and aesthetic problems.

Non-Destructive Testing for Defect Detection

Visual Inspection Methods

Visual inspection is the most widely used and less costly way of measuring surface defects. The visual examination requires good lighting, magnification characteristics and inspection process.

Radiographic Testing Applications

The radiographic test functions well in locating the internal defects like porosity, inclusions, and extensive unfusion. The technique gives permanent records and has the ability to analyse complex joint geometrics.

Ultrasonic Testing Advantages

The ultrasonic testing can give information in real-time concerning defects and also come up with detailed information concerning the size, defect location and defect orientation. It is quite powerful in the case of thick sections and complicated geometries.

Magnetic Particle Inspection

Magnetic particle inspection is well suited with the detection of surface and near-surface cracks on ferromagnetic materials. The technique is especially helpful in identifying the tightly spaced cracks which may not be visible with naked eyes.

Quality Control Systems

Welding Procedure Specifications

Quality fillet welds can be produced using proper welding procedure specifications (WPS) that describe the parameter and the methods to be used. The documents form the basis of quality consistency of welding.

Welder Qualification Programs

Certified welders are able to show that they have the capacity to give quality weld, without defects, as per the required standards. The process of requalification on a regular basis provides quality assurances and competency.

Inspection Documentation

Labour intensive records of inspection are documented to give traceability and quality assurance. It is through appropriate documents that trends are noticed and preventive measures taken in case there are defects concerning the electrode wire .

Statistical Process Control

Statistical process controls offer an effective way of monitoring the trend in the welding quality and predicting the issues causing defects prior to production of flawed fabrications. This initiative enhances the level of quality by addressing the most common welding defects .

Prevention Strategies and Best Practices

Base Metal Preparation

The background to welding free of defects is in good preparation of base metal, especially cleaning, fit-up of the parent metal and the welding joint geometry. Paying attention to these details averts most of the common welding defects in the welded structure weld bead.

Welding Parameter Optimization

To obtain a steady quality, it is better to optimize the welding parameters used in each application and in this manner specific materials. This involves present, voltage, travel velocity and the shielding gases option.

Environmental Control

Adjuvants of the environmental factors of wind, humidity and temperature allow the achievement of stable welding circumstances and lower the potential risk of the formation of defects.

Operator Training Programs

The wide-range training of the operators guarantees awareness of the causes and prevention measures of defect in the welders. Continuous training creates high quality levels and low defect ratio.

Industry Standards and Codes

AWS Welding Standards

The American Welding Society (AWS) standards offer exhaustive provisions regarding the quality of welding, e.g. criterion of defect acceptance and welding inspection procedures of different applications.

ASME Code Requirements

Specific requirements governing the welding operations performing in pressure vessels are provided in ASME Boiler and Pressure Vessel Code with elaborated rules regarding welding defect acceptance, and repair operations.

ISO Welding Standards

International Organization for Standardization (ISO) standards of welding offer world-regulated standards in qualifying the quality of welding and welding faults assessment among various aspects of industry.

Industry-Specific Requirements

Specific industries also have certain requirements which might be stricter than general requirements. These requirements are crucial in assuring maintenance of compliance and quality.

Economic Impact of Welding Defects

Cost of Defect Repair

The costs of repairing welding defects may be significant such as the cost of removing the material, doing the re-welding as well as the other inspection needs that may be necessary. It is usually more economical to avoid something than it is to fix it.

Production Schedule Impact

Repair of defects may have great effect on production schedules especially in the operations that lie in the critical path. Efficient planning and prevention techniques, such as those used in mig welding, allow reducing disruption in the schedule.

Warranty and Liability Issues

Defects in welding may cause claim of warranties and liabilities especially on structural applications. Building high standards of quality assists in reduction of these risks.

Customer Satisfaction

Unity in quality of welding enhances customer satisfaction and long term business relationships. In competitive markets, quality reputation is an important thing.

About GWT Worldwide

Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) is a leading provider of professional logistic services whose focuses are global freight forwarding, supply chain and cross-border e-commerce logistics. We offer full-service air and sea transportation, China-Europe transport by railway, cross-border services, international express delivery, customs clearance, warehouse service, and FBA shipping logistics to and from the Amazon. As your custom logistics partner of a smooth international business, we emphasize efficiency, openness and customer satisfaction.

บทสรุป

Another major challenge in the manufacturing and construction industries is welding defects, however, knowing about its causes and the corrective preventive measures that can be put in place can lead to an extraordinary decrease in the development of such weld imperfection defects. The basic sources of welding defects are wrong welding patterns, the choice of materials, expertise or machine configuration, hence a thorough training and quality control systems are vital to ensure predictable effects.

Effective prevention of defects involves a well-defined process including effective welding processes and operators, correct equipment, extensive quality control systems, etc. Organizations can attain high quality results of welding with a reduced level of expenditure by adopting these strategies and ensuring the set focus on continuous improvement.