คำอธิบายเมตา: Learn everything you need to know about plastic materials in automobiles, what it is, how it is used, advantages and its production. Find out how plastics transform modern vehicle design, performance automotive manufacturing.

The motor car industry has experienced an extraordinarily impressive change in the last few decades, whereby plastic substances are becoming a central figure in car production. Whether it is a lightweight body panel or the advanced interior features automotive plastics have changed the way vehicles are designed plastic automotive parts, built and. With this in-depth guide, the reader will be taken through the complex world of automotive plastic materials and their various types of use, advantages, and possible future when the world is continually changing in the manner in which cars are designed.

Understanding Automotive Plastic Materials

Auto parts plastics are a benign lineage of synthetics existing in a composite of polymers that are deliberately being created to address the rigorous needs of vehicles manufacturing heat resistance. They incorporate high strength along with very low weight and are used in auto design in a variety of vehicles. Adoption of plastics in the automobile industry has helped the manufacturers to attain efficient fuel usage, increased protection and an enhanced aesthetic beauty coupled with affordable prices glass reinforced car bodies.

The use of plastic in the automotive industry is brought about by the fact that these materials can be shaped in any complicated form, their inability to corrode, and absorb energy in case of impact engine covers. These properties render them suitable in many automotive applications that include structural components, ornamental attributes, among others.

Primary Types of Automotive Plastics

The automotive industry has many applications of different types of plastic materials because it makes specific choices in terms of application based on the features of the different materials cable insulation. Thermoplastics that are recyclable and can be recycled indefinitely by heat and reshaping, occupy the major plastic cars playground.

Polypropylene (PP) is the most commonly used automotive plastic and has superior chemical resistance combined with exceptionally low density. Polyethylene (PE), offers better impact resistance and it is widely applied in fuel tanks, protective elements and other parts. The acrylonitrile butadiene styrene (ABS) is excellent in providing strength and in surface finish quality which makes it most suitable in interior trims and dash components.

Engineering Plastics in Automotive Applications

Engineering plastics are an advanced grade of vehicular material that holds the ability to sustain harsh conditions and still retain its structure. These specialty polymers have excellent mechanical property, thermal and chemical resistance than the commodity plastics.

Polyamide (PA) also called a nylon, has outstanding strength-weight ratio and can be found in numerous applications in a realm of engine and air intake manifold and structural components. Polyoxymethylene (POM) also has very good dimensional stability along with very low friction making it ideal in any precision component such as gears and fuel system components.

Reinforced Plastic Composites

The combination of reinforcing materials and plastic matrices has made a new batch of automotive materials that support the effects of both of sides. Glass fiber reinforced plastics (GFRP) have demonstrated increased strength and stiffness as well as the lightweight property needed to achieve greater fuel efficiency.

The ultimate composite material used in automobiles is Carbon fiber reinforced plastics (CFRP) because, unlike other composite materials, it offers the best strength-to-weight ratios, allowing manufacturers to achieve high-performance parts. Such materials are being applied even in luxury cars and competitive cars where light weight is an important consideration.

Interior Automotive Plastic Applications

The interior of the vehicle demonstrates the breadth of functionality and aesthetic possibilabilities of the automotive plastics. The assemblies of the dashboards, the panels of the doors, the seat parts, the parts of the trim are all very dependent on the assortment of plastic to provide this functionality and aesthetic value.

Soft-touch plastics have transformed the interior design industry since they serve the purpose of luxury feel and outlook as well as durability and affordability. Such materials also tend to have special additives and special coatings so that they meet required tactile qualities and scratch resistance.

Exterior Automotive Plastic Components

Automotive exterior services require plastic materials that are resistant to severe environmental factors such as UV radiations, temperature changes, and chemical treatment. Bumpers, grilles, body parts, and lights all use special formulations of plastics that should be of outdoor durability.

The exterior automotive plastics require weather-resistant additives and ultraviolet (UV) stabilizers that guarantee their long-term operation and the continued presence of color. Plastic has the quality of attaining complicated shape and features, such as integrating various designs, which are eminent in the modern aerodynamics design.

Engine Bay Plastic Applications

Engine compartment exposes plastic material to extreme temperatures, chemicals and mechanical stress hence making this field an interesting one with regard to plastic materials. Plastic of high temperature resistance like polyamide, polyoxymethylene and specialized thermoplastic elastomers like air intake systems, cooling system parts, and electrical housing etc needs to be done.

These materials have to be stable in high and low temperatures and be capable of surviving automotive fluids and chemicals that are normally present in the engine.

Manufacturing Processes for Automotive Plastics

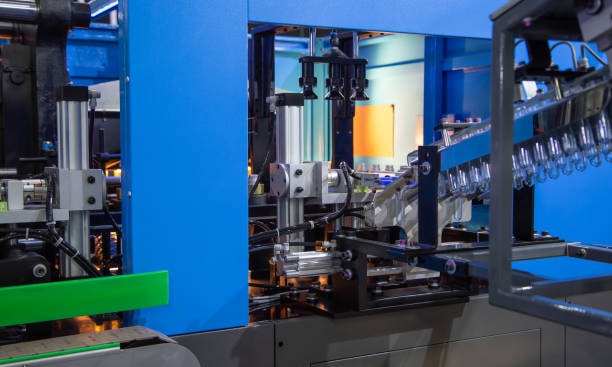

The manufacturing of car plastic parts is a complex process of manufacturing that needs different manufacturing processes depending on the conditions of the targeted product. Injection molding is the most widespread one as it exhibits great precision, great finish and it is cost effective to produce in mass.

There is wide application of blow molding with hollow parts like fuel tanks, air ducts and fluid reservoirs. The thermoforming processes allow a large complex panel to be produced requiring little tooling investment and therefore suited to the development of prototypes and low volume production.

Quality Standards and Testing Requirements

The quality standards of plastics in automobiles have to be high, and these materials are to undergo strict testing procedures to be considered as safe, durable, and performing. Material qualification and component validation are given in international standards including ISO, ASTM, and SAE.

The tests include mechanical properties, thermal testing, chemical resistance, burning and long term durability in different environmental conditions. These extensive test processes make sure that the plastic parts are going to work dependably during the use life of the vehicle.

Sustainability and Recycling Considerations

The consideration of the environment has found the car as one of the major factors in the selection and use of plastic material. Producers placed more emphasis on recycled content, bio-based materials and the design of the components in a recyclable end-of-life.

The auto plastics waste can be recycled through the closed-loop systems, which restores and re-converts the waste to automotive parts, hence the principles of circular economy. Recycled automotive plastics have become an option over actual materials due to the upgrading of sorting and cleaning technologies.

Future Trends in Automotive Plastics

One of the rapidly developing industries lately is the automotive plastic, and new technologies have been added and the market demands are evolving. The implementation of the concept of smart plastics, which provides sensors and electronic capability within the plastic has brought new horizons to consolidated vehicle systems and superior customer experiences.

Additive manufacturing technologies are allowing fast prototyping and low volume production of complex plastic parts to speed up the product development process and make mass customisation possible. Biodegradable and bio-based plastics Bio-based and biodegradable plastics are now being considered as sustainable alternatives to non-critical applications.

Supply Chain and Global Logistics

The plastic supply chain in the automotive industry is multi-national, and it involves complex logistic solutions that should provide timely supply and the preservation of quality. Shenzhen Guanwutong international freight forwarding co.,ltd.(GWT Worldwide), as a professional logistic partner is focused on global freight forwarding and supply chain solutions of automotive materials. Their end to end services such as air freight, sea freight, China-Europe railway and customs clearance guarantees effective transportation of automotive plastic material produced by manufacturers to assembly companies all over the world.

Cost Considerations and Economic Impact

Economic benefits of automotive plastics are not only limited to the cost of materials but also include manufacturing efficiency, the reduction of costs in weight as well as their life cycle. Capability of locating several functions in one plastic mold manufacture simplifies assembly and lowers costs of labor as well as enhancing quality and reliability.

Plastic replacement results in a direct weight reduction which results in enhanced fuel efficiency and low emissions, something that bears economic benefits as long as the vehicle is on the road.

Innovation and Research Development

Innovation of the automotive plastic materials is fuelled by constant research and development programs aimed at developing superior performance, environmental and economic aspects. The incorporation of nanotechnology is developing materials having new properties never enjoyed and the concepts of smart materials offer revolutionary feats.

New-gen automotive plastic solutions are developed and commercialized at a faster rate because of the efforts carried out mutually by material suppliers, automotive manufacturers, and research institutions.

Regulatory Compliance and Safety Standards

Plastic automotive materials are required to meet more and more difficult safety and environmental regulations in the global markets. Regulatory standards deal with issues of occupant safety, emissions, disposal and recycle standards at end-of-life.

Manufacturers face intense regulations on one side and competition on cost and performance on the other side, and need advanced material selection processes and material validation processes.

Market Outlook and Industry Trends

Worldwide automotive plastics market is steadily growing with the growing vehicle production, light-weighting programs and changing taste of the consumers. The growth in the use of electric vehicles is opening up new market potential in the battery housing, thermal management systems and structural applications of plastic material.

The use of automotive plastics and the direction of the development of new materials will be determined by regional market forces, technology trends, and consumer requirements of sustainability.

บทสรุป

Plastic materials used in nature automobiles have radically changed the automotive industry; as it has helped car manufacturers to produce vehicles that are nimbler, safer and cost less to run, and good-looking. The wide variety of available types of plastic, including commodity thermoplastics as well as advanced composites, gives designers the freedom they have never had to solve challenging engineering problems. In a future that is still in growth towards the direction of electrification and sustainability, plastic materials will become the most pivotal in the determination of future mobility.