In precision manufacturing, perfect flatness is [of] essence to cutting right, fitting and functioning of parts. Because flatness is a core geometric dimensioning and tolerancing (GD&T) principle, it is important in controlling quality across manufacturing: automotive connector brake molds, semiconductor packaging components and more.

What is Flatness?

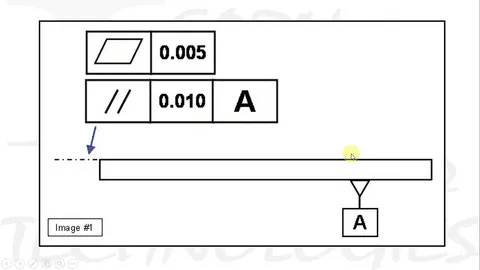

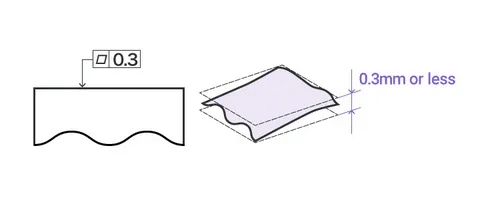

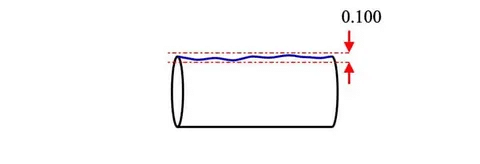

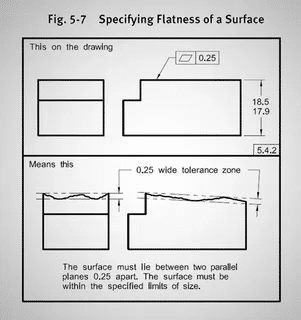

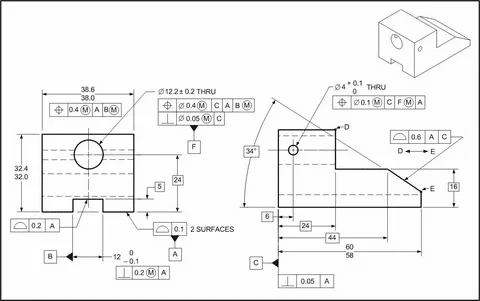

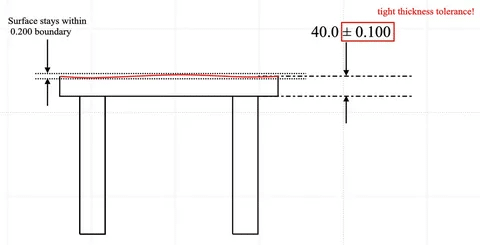

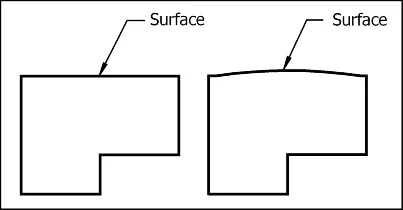

Flatness is a form type of GD&T like tolerance, which regulates the extent, to which a surface may not resemble a plane surface. Contrary to straightness, which is applied to individual lines, flatness refers to an overall evaluation to assess a whole surface area. The symbol of flatness ( 99 ) means that any point on the given surface should fall between two parallel planes whose distance is equal to the tolerance.

Technically, the flatness marks a state of having all elements of a given surface with elements falling within a tolerance zone that tends to comprise two parallel planes. This control of geometry also makes sure that the surfaces are very well dimensioned to guarantee the fact that they can be assembled well with each other and that they behaved within the precision applications as well.

How is Flatness Evaluated?

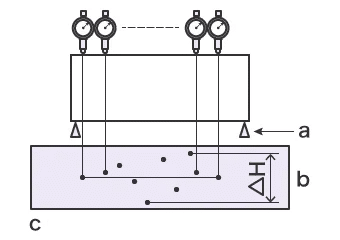

The process of flatness measurement determines how well the supposedly ideal plane was as compared to the surface points. Included in the process are:

Surface sampling: Several points are sampled with the surface using highly sensitive instruments. Surface area and accuracy determine the concentration of measuring points.

Plane Fitting: Plane is fit mathematically a best-fit plane is computed using the measured points by adjusted algorithms (least-squares). This aircraft is the point of reference of deviations.

Deviation recognition: maximum positive and negative deviations to the plane of reference are determined. The flatness error is comprised of the total variation of the highest and lowest points.

Tolerance Verification: The value of the flatness error is compared with the patience expressed as an acceptance/ rejection.

This is done manually nowadays and modern coordinate measuring machines (CMMs) and laser scanning systems automate this process by giving rapid and accurate measurements of flatness required in high volume precision manufacture.

Why is Evaluating Flatness Important?

The evaluation of flatness is important to some manufacturing and functional considerations:

Assembly Performance: Bad flatness may not allow the assembly of parts, which will produce gaps, misalignment, and reduction of performance. Direct contact with electrical reliability is found in connector molds: here flatness plays a key role.

Sealed Integrity: In various applications, applicators use flat surfaces when it comes to gaskets or O-rings. Surface variation may lead to leakage within the hydraulic machinery, medical equipment and auto parts.

Manufacturing Consistency: When parts are in regular flatness inspection, then the consistency of a process is monitored and any tool wear, machine drift, or setup problems can be detected at an early stage and addressed before they cause poor quality, high wastage, or yield loss.

Cost Saving: A flatness issue identified early avoids costly field repairs and rework as well as scrap. Holding tight flatness tolerances can be far more cost effective than having down-stream assembly problems.

Customer Satisfaction: As a demonstration of manufacturing capability and to instil confidence among customers in quality and reliability of the product, the process of meeting specified flatness requirement will attract satisfaction.

Tools for Evaluating Flatness

A variety of measuring devices and methods are applicable to measure flatness; and each is specific to applications and levels of accuracy:

Coordinate Measuring Machines (CMMs): CMMs have the best accuracy of measuring flatness, with the possibility of being able to achieve tolerances of less than micrometers. CMMs are probed by touch or optical sensors to measure surface data points in a thorough manner.

Laser Interferometers: Perfect to measure flatness of optical surfaces and ultra precision components. With these instruments it is possible to detect deviations as small as fractions of wavelengths.

Dial Indicators and Surface Plates: Conventional way that would be applied in inspection in the shop floor. They are not as accurate as CMMs, but they give fast process-control feedback.

Laser Scanning Systems: Can be used to measure large surfaces in a fast non contacting manner. The systems produce surface maps covering the whole area with fine surface maps of variations of flatness.

Optical Profilometers:Offer high resolution surface Topography measurements which are desirable where there is a need to measure small precise components with nanometers resolution.

The selection of the measurement tool is based on such parameters as the needed accuracy, surface size, material character, and the requirement of the production volume.

Flatness Tolerance in GD&T

Flatness tolerance specification under GD&T utilises standard symbols and conventions that guarantee effective communication between designing and manufacturing departments:

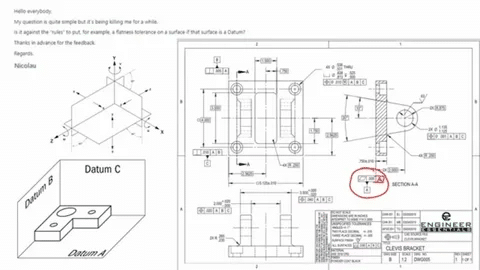

And Symbol Usage: The symbol, flatness (symbol190), is located in an active feature control frame and the tolerance value. There is no need to refer to any data as flatness is measured with respect to a surface itself.

Tolerance Zones: The given tolerance provides two similar planes, where all the points on the surface have to be present. These two planes will be separated by a distance that is the value of flatness tolerance.

Maximum and lesser material condition: Flatness is not allowed to be altered by a maximum material condition (MMC) or least material condition (LMC) as with other GD&T controls. It is irrespective of the real size of the feature.

Drawing Interpretation: The tolerances of flatness are usually much stricter in comparison to dimensional tolerances. In precision mold components, it is usual to have a flatness tolerance of value of >(0.001) mm.

Correlation with other tolerances: Flatness is related with other geometric tolerances such as parallelism, perpendicularity as well as position to allow adequate part functionality.

To initiate proper application of GD&T, one must know how flatness interacts with other geometric controls and manufacturing processes to obtain the best part performance.

Key Takeaways on Flatness Evaluation

The principles of flatness assessment allow the manufacturers to create better-quality parts with the optimization of their production cycles:

Process Control: The frequent process of monitoring flatness contributes to manufacturing stability and quality avoidance. Setting up capability-based control limits guarantee stable production.

Measurement Strategy: Choose a proper selection of measurement tools and techniques depending on the accuracy demand, surface, and the amount of production. Take into consideration precision and the throughput requirements.

Tolerance setting: Try to balance the need of a product to work in its functional demands and the limitations of the ability to manufacture it with regard to flatness tolerance. Unnecessary tight tolerances cause higher costs with no corresponding benefits.

Documentation: Keep proper records of the measurements taken to improve the process, customer needs and in meeting the requirements of the quality system. Such information is used in continuous improvement programs.

Training: The measurement personnel should be trained in the concepts of GD&T, techniques of measurement and how to run equipment. measurement uncertainty is minimized when measurements are conducted through properly trained personnel.

บทสรุป

One of the basic parameters of precision manufacturing quality assurance is flatness measurement. Measuring the quality of the component efficiently is achievable by ensuring that the management of the measurement principles is applied, the right measurement tools used and the right evaluation strategy employed in maintaining the efficiency of the manufacture process.

At Zecheng Precision, we have the sophisticated measuring ability and in depth knowledge of key principles of GD&T, which helps us produce mold components with fine flatness property. Having achieved a normal tolerance of +/-0.001 mm to dimensional accuracy, our typical tolerances have a surface roughness of Ra 0.025 to support the most challenging applications in automotive, medical and semiconductor industries.

The level of flatness, whether it is a case of developing automotive connector molds, precision plastic components, or tungsten-steel elements flatness will guarantee the maximum performance and customer satisfaction. The pallet of the financial credit attached to the measures in place to measure quality is evident on cost that is saved on refitting, ultimate assembly profit, and quality of the merchandise.