Meta Description: Find out all you need to know about the injection molding process, insert molding manufacturing process, advantages, applications in automobiles, healthcare, digital control panels, and electronics sector. Fully detailed guide, design and material considerations.

What is Insert Molding and Why It Matters in Modern Manufacturing

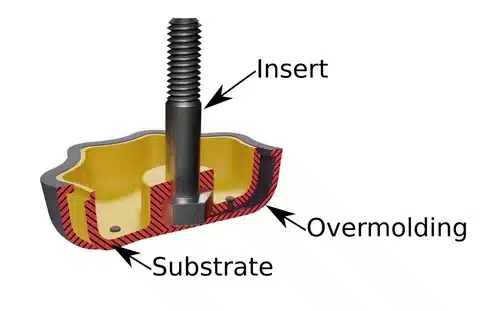

Insert molding helps in the production of parts that are sturdy, robust, and lightweight thus the reason why insert molding is being discovered by various industries. Insert molding Insert molding is a common plastic injection molding technology where the manufacturer is able to combine the engineering plastic with metal inserts or an insert of another material to make products with excellent wear resistance, low weight and high tensile strength.

Such an innovative production method has made it possible to change the way businesses produce very intricate parts by incorporating the durability of metal and the malleability and affordability of plastic. In cases where enterprises need stable logistics and supply chains as they produce parts of what they are selling, the Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide) offers the complete services of freight forwarding all over the world, such as air freight, sea freight, China-Europe railway transportation services, and Amazon FBA distribution services.

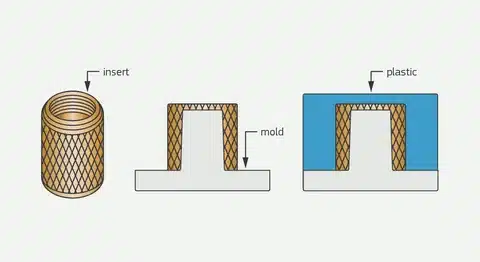

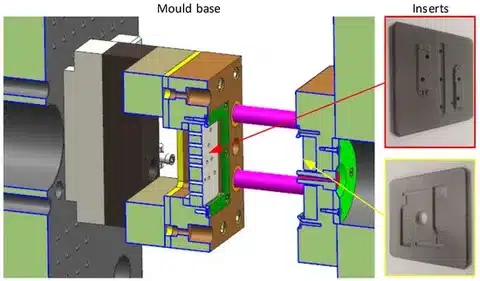

Understanding the Insert Molding Manufacturing Process

Insert molding starts by either injecting pre-formed inserts (usually metal or ceramic or other) into the mold cavity and insert cavity of the mold or stacking the inserts. When the plastic is in this condition the plastic will grow to become one with the insert, forming one and only piece. When injecting the molten plastic around the insert, a mechanical bond and, depending on the materials, also a chemical bond forms, which leads to a single part having superior properties.

This procedure should be accompanied by temperature control, correct positioning of the inserts and careful selection of material that should allow the best possible adhesion between the insert and the plastic material. Automation in modern insert molding plays an important role in creating consistency in the operations and lowering the production costs.

Key Benefits of Insert Molding Technology

Besides reducing assembly and labor costs, the process enables manufacturers to have more flexibility in their designs without having to compromise in the structural integrity and integrity of the part. The main merits cover a decrease in assembly, removal of secondary operations, a better part reliability, and mechanical properties.

Insert molding does not require any extra fastening, using adhesives or welding procedures, which leads to substantial savings of cost and enhancing efficiency of the production. The integrated design will also ensure that chances of failure of the component due to weakness or separation of joints is minimized.

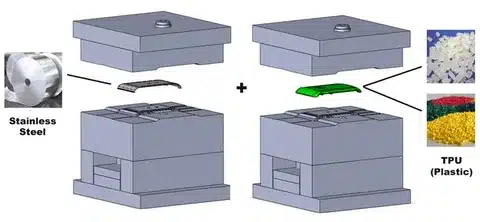

Material Selection for Insert Molding Applications

Insert molding is successful when the materials used are compatible and hence this becomes a success. The material of the insert has to be selected depending on bonding to the plastic required, the strength required as well as environment where it will be used in. Typical insert materials are stainless steel, brass, aluminum and different engineering plastics.

Plastics used to insert mold vary across the general household thermoplastics into specialized high discrimination engineering thermoplastics. The choice of thermoplastic resin material should be made with temperatures difference in thermal expansion, chemical resistance and environment use.

Design Considerations for Optimal Insert Molding Results

The insert molding design and great pride should be paid to the geometry of the inserts, the wall thickness, and the drafts. The insert design should be able to account thermal expansion causes between different materials and offer sufficient surface area so that it can be bonded correctly. Laser-cut parts that have sharp corners and stress concentrators need to be avoided as it will cause cracking or delamination.

Uniformity of the wall on all sides of the insert is a very important factor to avoid sink marks as well as uniform cooling. Placement of gate also should be considered in the design so that there is good molten material flow around the insert and there are fewer weld lines around the critical location.

Automotive Industry Applications of Insert Molding

Insert molding is largely carried out in automotive industries that are used in producing parts that are tough and durable to work efficiently and to be dependable as demanded by automobiles. The most common uses are dashboard assembly, sensor housings, electrical connectors and structural elements where there is the need to combine the metal strength and plastic functionality.

Parts that threaded fasteners, gears, and electrical senors are typical components that are typically metal parts inserted into mold in the automotive industry. Automotive industry The automotive industry uses the advantages of insert molding to develop light and rigid parts fulfilling strict safety and performance requirements.

Medical Device Manufacturing with Insert Molding

Medical: Plastics are sterilized easily and therefore medical practitioners would always like to use medical equipment components, such as insert components and insert-molded parts in defibrillators, pacemakers, medical cables and wiring. In its medical industry, insert molding finds great use in the development of biocompatible parts that are capable of withstanding sterilization methods without losing functionality.

Also, the production of some electronic devices used in the medical industry is feasible with the help of insert injection molding. Insert molding in the medical sector Having mentioned the general concepts of insert molding in the medical sector, some common instances can be seen in making of tubes, parts of medical equipment in use in skilled nursing facilities and dental instruments.

Electronics and Consumer Products Insert Molding

The insert molding is also used by manufacturers within the consumer electronic industry in order to not use fasteners and solders in manufacturing. Electronic uses are connector housings, cable assemblies, metal components switches, protective enclosures where electromagnetic shielding is desired or where the part has to be made unusually durable.

As an example, you can put computer chips or wires and encapsulate them in a plastic protective case. It is used to prevent reliability loss among electronic components in harsh settings as it minimizes the size and weight of entire merchandise.

Industrial and Defense Applications

Insert molding plays significant functions in the manufacturing of industrial machines where strong parts are constructed that can work under unfavorable conditions. Defense: Defense products produced using insert molding are binocular cases and other tactical items that are subjected to harsh environments and still have to produce results within themselves.

The applications of industrial usage include manufacture of equipment parts, specific tools and other fixtures that need compatibility of several properties of numerous materials in one and a unified piece.

Quality Control and Testing in Insert Molding

Insert molding has variety of quality control checks in the production procedure. In the critical parameters, we have insert positioning accuracy, bond strength testing, and metal inserts strengthen, dimensional checking as well as visual inspection of defect instances like delamination or missing flow.

Further tests available to increase confidence in the tests performed are the pull-out tests to confirm bond strength, thermal cycling tests to check long term durability and the non-destructive test techniques to determine the existence of defects within the structure deformation temperature. Quality control allows one to maintain uniformity of performance of a part, and minimize failures in the field.

Cost Analysis and Economic Benefits

Insert molding is highly economical because the cost of assembly is high, secondary operations are eliminated, and there is reliability of parts. Insert molding is deemed to be one of the best ways of producing lightweight and small components at the lowest costs heat treatment.

Insert molding tooling could cost more up-front than traditional molding do but the resulting reduced labor expenses, shorter production cycle, and high-quality pieces make the investment worthwhile in long production runs cost element.

Automated vs Manual Insert Molding Processes

This is a more preferred option of mass production, which would help in minimizing human error, augmenting efficiency, shortening of injection molding, and enhance reliability of the products plastic insert molding process. Automated insert molding supplies repeatable insert positioning and less cycle times and enhanced safety, in comparison with manual undertakings.

In low-volume operations, insert placement can be manually applicable or when a prototype needs to be produced but once the number of the manufactured item becomes high, especially for cost sensitive parts machine automation is impracticable due to the need to be consistent and time efficient insert injection molding process.

Insert Molding vs Traditional Assembly Methods

Insert molding helps you to have one part with metal and plastic components, which makes the risk of breaking off or separating with threaded inserts impossible and even gives higher strength, accuracy, and design capabilities as compared to manual assembly insert molding and overmolding. This comparative feature of bonding with Mechanical fastening or adhesive bonding systems makes insert molding a superior process mold opens.

Conventional assembly techniques usually involve extra effort, fixtures and quality control, insert molding does away with all this to make repairing very smooth with absolute part reliability metal insert molding.

Future Trends in Insert Molding Technology

Some of the future of insert molding is the use of more sophisticated material, automation systems, and connected to Industry 4.0. The new trends involve adoption of smart materials, monitoring of the process in real-time, and prediction maintenance systems- which improves efficiency of production conventional injection molding automated insertion.

Recycling of end-of-life parts, use of biodegradable suggestions at the insert material, as well as the development of a recycling program, show that insert molding can be implemented in a more environmentally-friendly manner or that it can be made a more environmentally friendly process without losing other virtues eliminates post molding assembly.

ผลกระทบต่อสิ่งแวดล้อมและความยั่งยืน

Insert molding is also sustainable, since it also reduces material, eliminates adhesives and fasteners, and makes parts more durable so they extend product life times. Use of recycled products in insert and plastic components is also possible through the process overmolding insert molding.

Benefits to the environment are a lower volume of waste and less energy input than in a multi-step assembly process, and the fact that end-of-life recycling of components can be an option, which is in line with the principles of circular economy liquid plastic.

Global Supply Chain and Logistics Considerations

The difficult global supply chains needed to manufacture insert molded parts can take on a complex pattern that needs good logistical support other materials. GWT worldwide deals with international freight forwarding, customs clearance and warehousing, which guarantee timely delivery of the raw materials and the finished parts to international markets plastic part.

Insert molding involves coordination of the supply of insert material and supply of the plastic resin material to the supply of the final product to multiple geographic areas making it an effective supply chain provided that effective management of this chain is implemented injection phase.

Troubleshooting Common Insert Molding Issues

Poor bonding, insert displacement, incomplete filling and thermal stress cracking are common insert molding problems excess material. Inherent troubleshooting strategies use process parameter, material and mold design analyses to find root cause remedies and follow up corrective measures rubber like plastic.

The steps in the prevention can be the use of quality material of a good selection, the optimization of the process parameters, frequent mold maintenance and effective training of the operators which would reduce the defects to the minimum and the quality would also be consistent injection unit.

บทสรุป

Insert molding is an innovative production process and has been insert molding explained, described as the process to combine benefits of several materials into one, compounded components. The benefits associated with this process include high part strength, manufacturing efficiency, and flexibility in the design across various industries such as the automotive, medical devices, electronics industries, and in the industrial equipment industries.

The potential of the technology to avoid the process of assembling and to enhance reliability of parts has made the technology a significant manufacturing process in terms of competitive edge that companies would want to enjoy in worldwide markets natural rubber. In ever-evolving automation and materials technology, insert molding will be one of the most significant processes in developing products in the next generation insert location