Meta Description: Learn the perfect milling stainless steel speeds and feeds that can be used in stainless steel machining. Discover professional tricks to prevent tool wear and maximize productivity and ideal surface finishes every single time.

Why Milling Stainless Steel is Challenging

Stainless steel boasts of its strength, ability to resist corrosion and corrosion resistance, the versatility and this has placed it as the king player in both the aerospace, medical, and industrial industries. But machining austenitic stainless steel is particularly hard due to its toughness and work hardening characteristics and low thermal conductivity. Knowing of the correct speeds and feeds is important in realizing clear cuts and in maximizing tool life.

1. Understanding the Nature of Stainless Steel

Stainless steel is alloyed and it is difficult to machine. Some stainless steel alloys common in use such as 304 and 316 form work-hardening at the early stages of the cutting thus causing augmented tool wear and chip removal difficulties. These can be solved drastically by the choice of proper feed rates and speeds.

2. Types of Stainless Steel and Their Machinability

Not every stainless steel acts in the same way:

- Martensitic (e.g. 410, 420): Machines easier but possibly has to be heat treated.

- Ferritic (e.g. 430): softer, easier to machine.

- Duplex: Equal resistance to strength and corrosion, yet hard to mill.

3. The Importance of Proper Speeds and Feeds

Proper speeds and feeds ensure less deflection of the cutting tools, possible maximum life of the cutters and good quality finish on the surface. High speeds may cause the tool to heat and work hardening may result in slow tool feeds, whereas a high feed rate can improve efficiency .

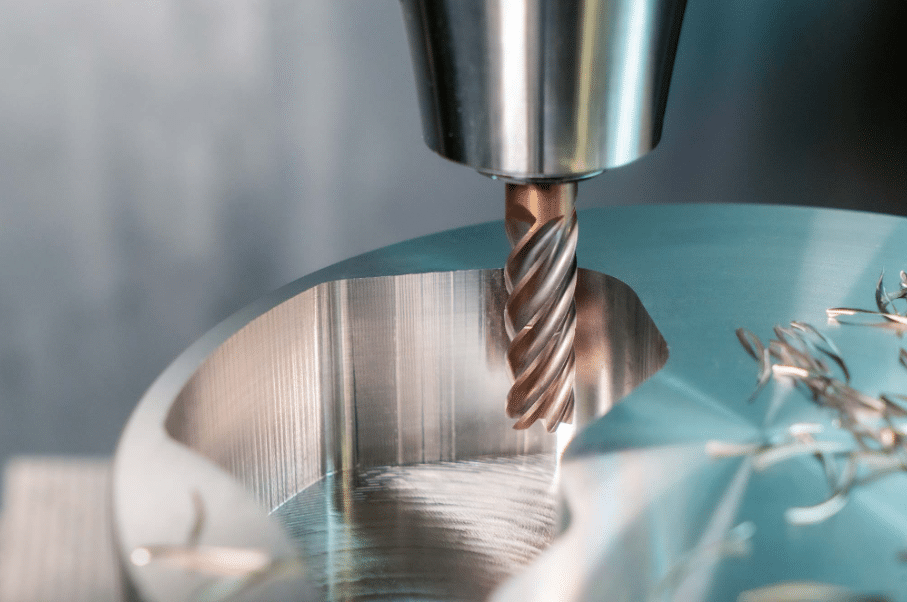

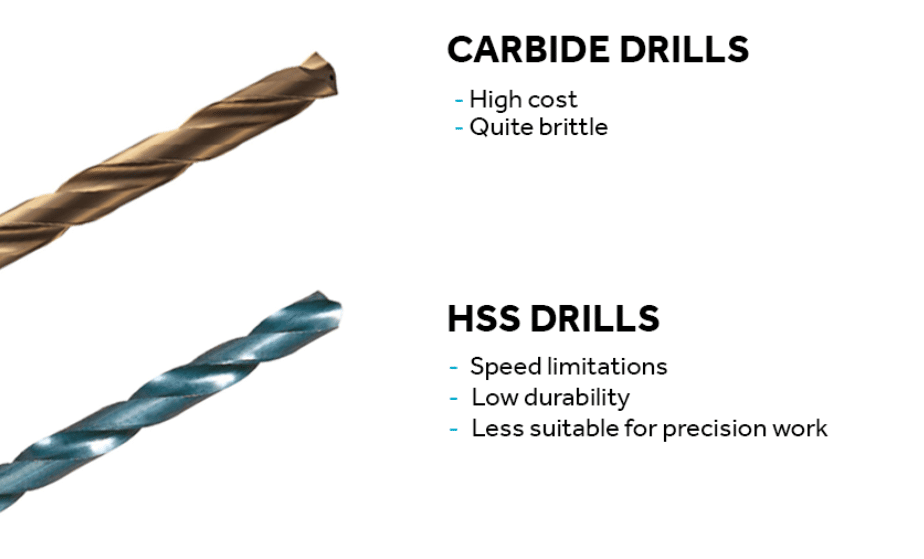

4. Tool Material Matters: Carbide vs. HSS

In the case of stainless steel, carbide end mills are normally preferred since they are heat resistant and rigid. Tool made of high speed steel (HSS) wears out, and can work with only soft grades or ones with low volumes.

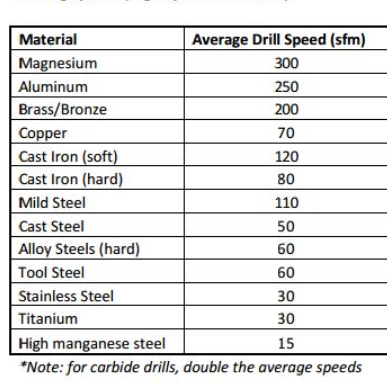

5. Optimal Cutting Speeds for Stainless Steel

Normal surface speeds:

- Carbide tools: 250 350 SFM (Surface Feet per Minute)

- HSS tools: 60- 100 SFM

Make setting adjustments using recommendations of various-grade and tool manufacturers.

6. Recommended Feed Rates

Use 0.0011.5 0.003 I/T (IPT) to finish and 0.0051 I/T to rough. Lower feed rates on small diameter tools and gradually up the feed rates as they become steady.

7. Depth of Cut and Width of Cut Guidelines

- Radial Depth (Width): finishing – 10 – 20 percent of the tool diameter; roughing up to 50 percent

- Depth: Deeper roughing passes, but not full width rivers cutting that subject the tool to stress

8. Use Coated Tools for Better Heat Resistance

The tools coated with TiAlN or AlTiN make the cutting process less frictional and well resistant to heat-build up. They extend sharp edges better, and mostly in situations where aggressive milling is done.

9. Avoid Work Hardening: Keep the Tool Cutting

Stainless steel has a tendency of work-hardening under light cuts and prolonged dwell time. A tool must always cut the material and always form chips evenly to avoid excessive vibration .

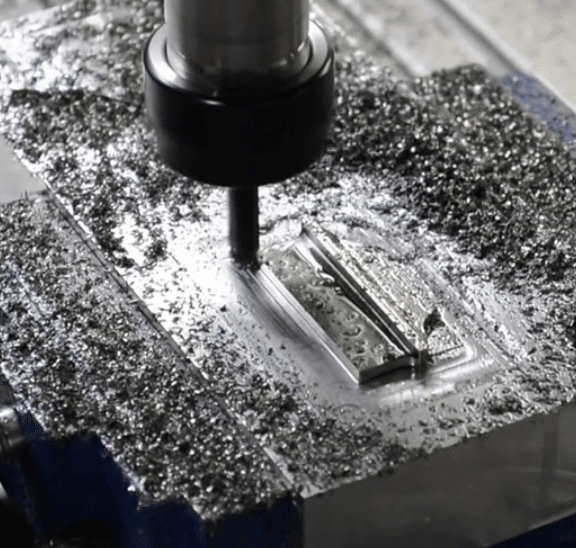

10. Chip Control and Evacuation

Ineffective chip evacuation enhances the wear and tear of tools as well as causing the built-up edge. Chips, particularly in deep pockets or slots are cleared by use of high-pressure coolant or air blasts.

11. Climb Milling vs. Conventional Milling

Stainless steels are recommended to use climb milling as a tool selection because it does not cause much wear-out to the tools and creates stronger surface finish due to less rubbing and chip welding.

12. Use of Coolants and Lubrication

To lessen the heat, to wash out chips, and to help it avoid thermal distortion, flood coolant is strongly advised. In arid conditions, select machineries that are dry milled with particular coating.

13. Spindle Speed and Feed Calculations

Compute with the formula:

- SFM = [RPM x Tool Diameter x pi] / 12

- After that, determine feed per tooth in order to have important feed rate:

- Feed = RPM (#Teeth) IPT

It is always important to check settings against manufacturers charts or digital machining calculators.

14. Toolpath Strategies for Success

Trochoidal milling, adaptive clearing, lessens the time of engagement and maximizes chip elimination. Full-slotting should be used only when it is a must.

15. Tool Deflection and Rigidity

Chatter is caused by excessively long tools or workpieces that are not bearing support. Keep the tool short and make sure that the workpiece is rigid to ensure high precision and long time before needing a change of the tool.

16. When to Use Peck Milling

Peck milling, short repeated passes, is useful in controlling the heat and chip cooling in deeper pockets or slots. But you should not peck too superficial to avoid work hardening.

17. Common Problems and Solutions

- Burr Formation: Sharp tools milling climbing:

- Built-Up Edge (BUE): Add feed slightly, or replace with coated tools

- Tool Wear: Gradually Lower speed, make the coolant oilier, substitute tool type

- Chatter: Reduce the bottom depth of cut or tighten the fixturing stainless steel parts

18. Monitoring Tool Life and Replacement

The tool life is based on material hardness, speed/feed rates and chip load. Also be on alert to the wear in the tools e.g. burning, dull edges, or vibrating too hard. Preventively renew durable instruments to prevent damages on parts duplex stainless steels.

19. Stainless Steel Machining: GWT Worldwide’s Role in Precision Logistics

The tool life is based on material hardness, speed/feed rates and chip load. Also be on alert to the wear in the tools e.g. burning, dull edges, or vibrating too hard. Preventively renew instruments to prevent damages on parts cemented carbide tools.

- Bulk Stainless Components Bulk stainless components movements are performed via Air and Sea Freight.

- In the area of CNC tool sellers, cross-border e-commerce services are provided cnc machining.

- Amazon FBA product delivery on custom-machined products

- Precision parts custom clearance and warehousing

- Emergency tooling deliveries via China Europe rail transportation

We are knowledgeable about how advanced manufacturing does its logistics at GWT Worldwide. Whether it is a shipment of valuable tooling or a final stainless steel good, we guarantee delivery in a safe, economical, timely fashion.

บทสรุป

Stainless steel milling is a stressful task which needs a profound knowledge of appropriate speeds, feeds and cutting solutions. It is possible to enhance productivity and part quality by selecting the right tool, cutting parameters optimization, and machining pitfalls avoidance machining stainless steel. Using best practices has the benefit of minimizing tools wear, time out and in general efficiency.