Meta Description: Look at the list of different types of corrosion resistant stainless steel that it consists of austenitic, ferritic, martensitic, duplex, and precipitation hardening, which exhibit varying corrosion resistance properties . Get to know about 304, 316, 410, and other steel forms of stainless used in industries.

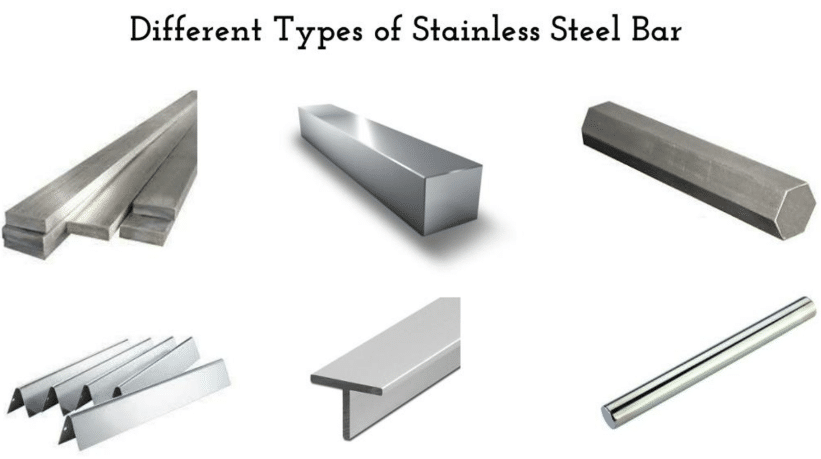

Introduction to Stainless Steel Classifications

Versatile and highly applicable in the contemporary economy, stainless steel has become one of the most adaptable as well as commonly used materials that possess remarkable resistance power, tensile strength, and durability. Knowledge of the various stainless steels is very essential in choosing the appropriate material of stainless steel in the various uses, both in construction and manufacturing, and special industry work.

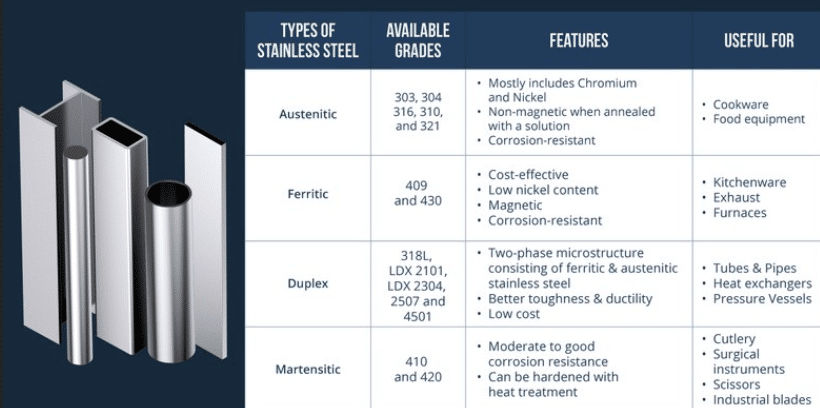

Stainless steel can be classified into five major families including austenitic, ferritic, martensitic, dual and precipitation hardening all with different properties and uses. This is a complete guide on these classifications which delves into these categories to aid you make the right choice on the projects and applications.

The Five Primary Categories of Stainless Steel

Stainless steel is classified into categories depending on their microstructure and metallurgical qualities. Both categories of lamps have some special features that can fit various settings and uses. The most prevalent type of stainless steel is 300 series, and although the most popular types are 304 stainless steel and 316 stainless steel, you need to be familiar with all the types in order to get the best temperature resistance material to use in chemical processing equipment .

Austenitic Stainless Steels: The Most Popular Choice

The most common type of all stainless steel alloys are the Austenitic stainless steel. They are known to have a face-centered cubic crystal structure; they also occur when austenite is kept at room temperature by adding large quantities of stabilizer elements of the austenite type, basically nickel and manganese.

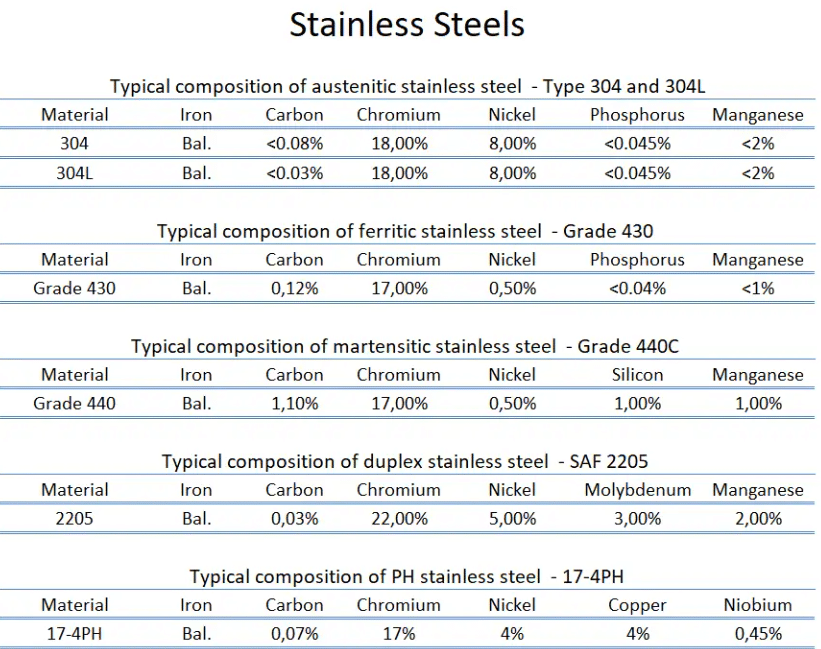

The Austenitic grade stainless steel can be further divided into smaller categories, however two grades of stainless steel 304 and 316 stainless steel are used mostly and most popular because of their best qualities. These steels average 16-26 percent chromium and 6-22 percent nickel, they are in non-magnetic state whenever annealed.

The austenitic family has outstanding corrosion resistance, decent formability and weldability thus suitable in food processing appliances, in architecture and in chemical processing industries. They are also non-magnetic in the annealed state and therefore can be used where it is important to keep magnetic interference at a minimum, which is a consideration related to their magnetic properties not all stainless steel .

Grade 304 Stainless Steel: The Workhorse of Industry

Grade 304 stainless steel is commonly called the work horse of the stainless steel industry because of its great combination of attributes and cost efficiency. This grade is an austenitic grade that has about 18-20 across the chromium bar and 8-10.5 nickel which makes them ideal alloys that offer decent levels of impact resistance and corrosion resistance in nearly any environment.

There is a lot of versatility in 304 stainless steel so it can be used extensively in kitchen equipment, food processing equipment, architectural trim and parts, auto parts, etc. It has good formability that can carry out deep drawing processes besides being weldable and hence ideal in fabricated structures.

Grade 316 Stainless Steel: Enhanced Corrosion Resistance

The designation Grade 316 stainless steel takes 304 as its basis but adds 2-3 percent molybdenum. This gives it much improved corrosion resistance to such things as chlorides and marines. The addition renders it the choice of 316 in coastal applications, marine hardware and chemistry processing apparatus.

The molybdenum contents of the 316 stainless steel are vital in enhancing resistance to crevice and pitting corrosion, and thus find applications in situations where the steel is exposed to acids, salt and other corrosive chemical compounds. Although in general it is more costly than 304, the improved performance makes it well worth it in stressful conditions.

Other Notable Austenitic Grades

In addition to the common grade 304 and grade 316 steels, there exist other commonly used stainless steel alloys, which have high applications in special situations. Grade 301 is strong due to work hardening, and therefore suitable in structural applications. Grade 321 adds titanium to inhibit precipitation of carbides to provide an improved high-temperature performance and intergranular corrosion resistance.

Grade 317 possesses a greater amount of molybdenum in comparison with 316 and offers even more pitting and crevice corrosion when compared to 316. This renders it appropriate in other, more active chemical settings where standard 316 might not be sufficient due to its poor corrosion resistance .

Ferritic Stainless Steels: Magnetic and Cost-Effective

The ferritic stainless steels are transversely structured and crystalized using body-centered cubic as well as magnetic. Such alloys are about 10.5-30% chromium, low carbon and low or no nickel content than austenitic grades and are therefore less expensive.

The ferritic group is noted to exhibit better resistance to corrosion, especially stress corrosion cracking and is also very resistant to nitric acids. They are magnetic, which makes them favourable in automotive exhaust systems, architectural use and appliances in which the high corrosion resistance provided by the austenitic grades is not necessary.

Grade 430 Stainless Steel: The Standard Ferritic

The most universal is ferritic grade Grade 430 stainless steel which consists of 1618% chromium. It provides acceptable corrosion resistance in the mildly corrosive conditions and shows great resistance to nitric acid. Its magnetic qualities and malleability qualify it as an ideal automotive trim, appliance and architectural material.

The low price of 430 compared to austenitic grades allows it to be economical in those applications where only moderate levels of corrosion resistance are required. Its robustness and weldability are however not as good as Austenitic grades.

Grade 409 and 410 Stainless Steels

Grade stainless 409 containing 10.5-11.75 chromium is the type of stainless steel at the bottom of the family. It provides bare minimum resistant against corrosion and is largely employed in automotive exhaust systems because of its low price and relatively good lifetime in high temperature applications.

Although technically grade 410 stainless steel is martensitic, it tends to fall into the same range as ferritic grades. It has 11.5-13.5% of chromium and can be made hard by heat treatment, and can therefore be used in cutlery, tools and pump shafts.

Martensitic Stainless Steels: High Strength and Hardness

The martensitic stainless steels can also be hardened relatively to the carbon steels by a heat treatment process. These alloys have comparatively more chromium content of 11.5-18 % and high carbon equivalent than other stainless steel families which enables them to form martensite on quenching.

The martensitic group provides exemplary strength and hardness post heat treatment and therefore, they are suitable in any app where strength is of essence like wear resistance and cutting capacity. Their corrosiveness is though normally less than that of austenitic and ferritic grades, and might need coating in hostile environments.

Grade 420 Stainless Steel: The Cutlery Grade

Grade 420 stainless steel- It is the most commonly found martensitic grade, which has compositions around 12-14% chromium and 0.15% minimum carbon. The composition can be hardened to a high degree by heat-treating it and can be made as hard as 50HRC.

Due to good corrosion resistance at mild environments and the high hardness, 420 stainless steel is suitable to be used in cutlery, surgical knives, and valve parts. It is especially practical in cutting tasks; it holds and retains a clean sharp edge creep resistance.

Grade 440 Stainless Steel: Maximum Hardness

The high-carbon part of the martensitic family is grade 440 stainless steel, which has three subgroups (440A, 440B and 440C), with gradually more carbon. The most hard stainless steel grade 440C containing about 0.95-1.20 % of carbon can reach the upper part of hardness.

These martensitic high carbon grades find application in ball bearings, valve parts and cutting tools where the highest possible wear resistance and hardness is necessary. It is true that the increased carbon levels lower the corrosion resistance of the higher-carbon martensitic grades.

Duplex Stainless Steels: Balanced Performance

Duplex stainless steels take the advantageous features of both austenitic and ferritic structures, with a microstructure that contains some 50 percent austenite and 50 ferrite. This two phase structure offers better strength than austenitic grades, especially against chloride stress corrosion cracking and also has good corrosion resistance and toughness.

Dupex family is very resistant to stress corrosion cracking and pitting corrosion and is suitable in marine environment, chemical process applications and oil and gas sectors. The increased strength enables them to be of thinner sections, which would save material cost even though the alloy content is higher.

Grade 2205 Duplex Stainless Steel

The most common duplex stainless steel grade is grade 2205, with about 22 percent chromium, 3 m o l y b d e n and 5 to 6 percent nickel. The material, which gives this composition an excellent corrosion resistance, associated with high strength, is applicable as a pressure vessel, piping system and maritime material.

The balanced microstructure of 2205 offers about 2 times the yield strength of austenitics grades such as 316 permitting major weight and cost savings in structural applications. It is especially useful at marine sites because of its superior chloride resistance to stress corrosion cracking.

Super Duplex Stainless Steels

Grade 2507 has increased alloy content than the normal grades of duplex stainless steel, which offers greater corrosive resistance than the standard structure. The alloys are normally made of 25 percent chromium, 4 percent molybdenum, and 7 percent nickel.

Due to their high quality of corrosion resistance, super duplex grades can be used when requiring stronger protection than can be offered with standard duplex grades, in offshore oil platforms, desalination plants, and chemical processing apparatus, requiring heat resistance. They are also very strong and can save heavy construction weights.

Precipitation Hardening Stainless Steels: Aerospace Performance

By heat treatment, precipitation hardening (PH) stainless steels can be toughened to high levels of strength with economy of good corrosion resistence. Such alloys include metal elements like aluminum, copper or titanium and have a strengthening precipitate (treatment of aging heat).

The PH family has the corrosion resistance of stainless steel and the strength equivalent to high-strength alloy steels so they are well suited to aerospace and high-performance applications and to nuclear applications where the two properties are essential.

Grade 17-4 PH Stainless Steel

Type 17-4 PH is the most typical precipitation hardening stainless steel that has around 17% chromium, 4 percent nickel, and 4 percent copper contents. It is alloyed with copper to enable precipitation hardening, to give strengths of up to 1,400 MPa (200 ksi), and retains good resistance to corrosion.

It is extensively used at aerospace, valve parts and pump shafts where high strength and corrosion resistance are both desired. It has great mechanical properties, which lure it to be applied in demanding applications; its price is also moderate.

Grade 15-5 PH Stainless Steel

Grade 15-5 PH: Grade 15-5 PH is similar to grade 17-4 PH although it contains a different composition; it has 15 percent chromium and 5 percent nickel. The grade is of great combination of strength, and corrosion, as well as good transverse properties.

The balanced composition of 15-5 PH qualifies it to handle tasks that need good toughness besides high strength like an aerospace product and high-quality shafting industry.

Specialized Stainless Steel Grades

In addition to these major groups, there are many more specialized grades of stainless steel each with, potentially, an application. These consist of grades to high temperature furnace conditions, severe corrosive conditions (super austenitic grades) and those cost-sensitive applications (leaned duplex grades).

These grades which are specialized in nature tend to add specialized alloying elements to affect special properties such as oxidation resistant silicon, pitting resistant molybdenum, or strength enhancing nitrogen.

Selection Criteria for Stainless Steel Types

The selection of stainless steel type does entail certain disadvantages as various factors need to be properly considered such as: type of stainless steel needed in terms of resistance to corrosion, mechanical characteristics, temperature requirements or even costs. The environment in which a company operates is also major factor in choosing materials.

In marine applications, grades that contain high seabed resistive molybdenum like 316 or duplex grades are required. Grades that are stabilized with titanium or niobium can be used in high temperature applications and high strength of duplex or precipitation hardening grades can be used in structural applications.

Applications Across Industries

The type of stainless steel preferred by different industries depends on their special need. Food and beverage industry use 304 and 316 mostly since it is very resistant to corrosion and can be cleaned easily, making them suitable for mildly corrosive environments . More commonly, more specific grades like super austenitic or duplex steels may be needed by the oil and gas industry as well as chemical processing industry.

Exhaust systems in the automotive industry are made utilizing ferritic grades such as 409 and 430; precipitation hardening grades are used in the aerospace industry to form critical parts of a structure. Getting acquainted with this industry preferences assists in the choice of materials.

Manufacturing and Fabrication Considerations

The method of manufacture contributes a lot to the choice of the stainless steel. There are grades that are very formable in deep drawing applications and others are enhanced in machinability where parts require precision. Much distinction also exists in the welding characteristics when comparing grades.

The austenitic grades tend to have the most ductile and weldable properties and thus these are the most ideal grades in fabricated structures. Martensitic grades possibly need special welding methods and following post welding heat treatment, whereas precipitation hardening grades demand close regulation of the heat treatment processes.

Cost Factors and Economic Considerations

There is a wide disparity in the price of stainless steel by grade and this is predominantly dimensional depending on alloy content, notably nickel and molybdenum. The costliest ferritic grades are usually the most cost effective whereas super duplex and precipitation hardening grades are the most expensive ferritic steel.

Factors such as cost of first materials involved in the construction as well as the lifecycle costs that are involved like maintenance, frequency of replacement and complexity involved in fabrication should also be analyzed in economic terms standard austenitic stainless steel. The purchased materials of higher grades might be explainable by their long service life and minor maintenance needs stainless steel scrap.

Future Trends in Stainless Steel Development

Stainless steel industry is still advancing as progress is made towards new grades that possess greater properties, including high thermal conductivity, and are more sustainable and economical. Lean duplex grades also offer increased strength to replace more costly nickel-based grades to structures stainless steel production.

Research is conducted to prepare grades which can perform better under special conditions, i.e., better high temperature properties, wear resistance, or corrosion resistance to aggressive media. These breakthroughs increase the usage scope of stainless steel materials.

About GWT Worldwide

Shenzhen Guanwutong International Freight Forwarding Co.,Ltd. (GWT Worldwide) is a certified freight forwarder specialized in worldwide freight forwarding, chain supply and cross border e-commerce delivery. Having experience in the work with stainless steel and other industrial materials oxidation resistance, GWT Worldwide provides all-round logistic services related to air freight, sea freight, China-European railway transportation, customs clearance, and Amazon FBA shipping support to guarantee successful and compliant transportation of materials all over the world.

บทสรุป

Different forms of stainless steel are important to understand in order to make proper decisions regarding material choices in the different applications. All the types – austenitic, ferritic, martensitic, duplex and precipitation hardening – have distinctive features suitable to particular conditions and demands. Grade 304 and 316 austenitic steel grades are the very commonly used types since they have an excellent performance in a general application and specialized grades can be used in the aerospace, marine, gas industry and chemical processing sectors as well. It is good to consider the corrosion resistance, mechanical properties, factors of the fabrication process and economical outcomes of a material that is to be effectively selected.