The process of welding is still one of the most important ones in the contemporary manufacturing, construction and repairing sector. Whether it is designing a skyscraper or making intricate metal designs, learning to know the various forms of welding styles and techniques, considering factors like material thickness, is a must to anyone dealing with metals. This extensive guide touches upon the existing welding techniques, their uses, and the role they play in manufacturing and logistics processes all around the world.

We realize the essence of quality manufacturing processes such as welding in our products that we ship across the world in Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT Worldwide). Due to the wide usage and applications of welded products such as parts of automobiles, aggregates, and building materials, we have transported millions of these products to their destinations, one being through our air freight, sea freight, and the China-Europe railway freight transport services as we are a professional logistics service controller of such services.

Gas Metal Arc Welding (MIG/GMAW): The Versatile Choice

Gas Metal Arc Welding or simply MIG welding or GMAW is by far one of the most common welding processes in the contemporary manufacture. A continuously fed wire electrode and a shielding inert gas is employed to shelter the weld against atmospheric contamination. MIG welding has the advantage of being able to butt weld on thin and thick materials including aluminum to stainless steel, often resulting in effective penetration welds .

The main benefit of MIG welding is that they are very easy to use and have very high productivity levels. It is suitable in production work because a clean and consistent weld can be accomplished by a welder, requiring a minimum of subsequent cleaning up. The procedure performs superbly on the material which falls within the range of 0.5mm to 25mm, whether it involves welding one or both plates, including groove welds. and this has a very broad application in automotive body work, structural steel fabrication among many others.

MIG Welding is especially useful to industries as a speed-quality combination is offered. Vehicle production manufacturers extensively use this technique for sheet metal fabrication to manufacture fillet weld vehicle body panels and vehicle frames. whilst furniture producers extensively use it to create metal furniture that is long lasting. The long and unending nature of weld in continuous wire feed system means that the production time is reduced tremendously when joining two pieces of metal as compared to other welding procedures.

Tungsten Inert Gas Welding (TIG/GTAW): Precision at Its Finest weld joint

Tungsten Inert Gas or the TIG welding or the GTAW is the epitome of precision and quality of welds. The non-consumable electrode is tungsten, which forms the arc, however manually introducing filler rods into the weld pool occurs separately. All the processing takes place under an inert gas blanket (usually argon), which in the case of exposed metal surfaces, serves to prevent contamination.

The TIG welding has the advantage of the best assurance of high quality welds with high degree of control over the heat input and penetration. This renders it the ideal option in all-important tasks where square groove stability in welds is crucial like aerospace elements, nuclear weapons facilities, and pressure pipelines. The procedure is capable of welding nearly all metals such as dissimilar metals and exotic alloys.

It is very skillful and needs a lot of training to be perfected but TIG welding is of high quality. he should co-ordinate the use of the torch, filler rod and the foot pedal at the same time and correct the arc length and speed of the travel. The complexity leads to low welding speeds compared to other processes, but with practice, it can lead to a stronger weld, making it costly to use it in high volume compared to specialist welds.

Shielded Metal Arc Welding (SMAW/Stick): The Traditional Workhorse

The most basic and geographically wide-spread type of welding, Shielded Metal Arc Welding (which is often known as the stick welding or SMAW) is still quite common in the community of welders. Consumable electrode This process consists of using a consumable electrode covered with flux that releases the protective atmosphere and various joint types as a supplementary filler metal as it burns. Stick welding is easy to use and very flexible therefore it is unavoidable in field work and repair jobs.

The fact that stick welding has portability is simply an understatement. As compared to other types of welds which demand gas cylinders and other complicated materials, stick welding only requires power and electrodes. This can be used ideally in outdoor constructions, pipe laying tasks for piping systems, and also during emergency repairs whereby movement is very important. It also performs well in windy environments in which gas-shielded processes would be difficult.

Stick Welding is highly suitable when welding thick material as well as when welding material covered with rust, paint, etc. Stick Welding is also used more often than most other processes to penetrate under a rusted shell. It is valuable for maintenance and repair jobs when the preparation of the surface to perfection is not always an achievable goal. Information is however less given on the process as it generates more spatter and takes more post-weld cleaning than other methods.

Flux-Cored Arc Welding (FCAW): High-Speed Production Solution

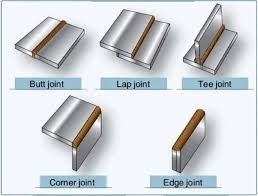

Flux-Cored Arc Welding is yet another advancement in the welding industry, and it is deemed as a merger of the flux protection of the stick welding and the continuous wire feed of the MIG welding. It makes a use of lap joint weld tubular wire filled with compounds of flux, but it can also be adapted to perform a butt weld depending on the formulation of the specific type of flux.

FCAW is also very popular in the heavy construction and shipbuilding industries because of high rates of deposition possible with it. Deposition and penetration rates achieved by welders exceed the solid wire MIG welding by a wide margin so thick section welding becomes economical. In the actual applications, the process is more forgiving than solid wire processes, it is better at dealing with gaps and fit-up variations.

Particular advantages of self-shielded flux-cored welding in outdoor situations are seen where external shielding gas would be swept away by wind. The variant is great in terms of portability and is designed to achieve maximum strength more productive than stick welding. For applications where higher mechanical properties are essential the dual-shield version (both flux core and external gas) gives an even higher quality and appearance of the weld.

Submerged Arc Welding (SAW): Industrial Powerhouse

Submerged Arc Welding is the last word in high productivity welding processes in the heavy industrial fields. This is done by automatic or semi automatic means and weights down the arc beneath a mass of granular flux, so that the welding process itself can not be seen. The flux does not only provide protection to the weld but also partakes in weld chemistry and mechanical properties of the weld.

The superior penetration facility of the SAW means it is ideal covering welding a substantial unit part in one run thus drastically cutting the time and cost of welding. The manufacturing of pressure vessel products, structural steelwork and vessel manufacturing industries, especially ship building industries have come to rely on this process in joining thick plate more effectively. The deposition rates in the process can reach a rate of ten times more as compared to that of manual welding processes.

The second great benefit of the submerged arc welding is consistency of quality. The repeatability of the weld parameters is determined by the automated character and the fixed operating parameters, vital in the re duction of mechanical properties needed in specific applications. The technology creates even, smooth and almost spatter free welds and usually necessitates no grinding following its welding.

Gas Tungsten Arc Welding Applications: Specialized Industries

Gas Tungsten Arc Welding finds its niche in the industries where the quality of welds takes the place of speed factor. TIG welding figures prominently in the aerospace industry where aluminum airframe and steel or titanium parts of the aircraft are joined and exotic alloys applied in jet engines. The fine manipulation of the amount of heat added minimizes the occurrence of distortion in thin material and not leaving some areas penetrated in crucial joins.

Food and pharmaceutical industries require the high corrosion resistance and cleanliness of stainless steel food and pharmaceutical equipment which TIG welding brings to that industry. With sanitary welding with the TIG processes, a smooth, non-crevice butt joints with no welding residues is obtained which results in bacterium being inhibited and easy to clean. TIG welding is used in the nuclear power plants in the primary system parts, where radiation needs high integrity welds.

TIG welding has artistic and architectural applications where beautiful precise joint can be produced in decorative metalwork. TIG welding is implemented by sculptors and metal workers in the architectural area, because the techniques allow joining two pieces of metal without burn through, offering great control over the appearance and penetration of the weld.

Advanced Welding Technologies: Laser and Electron Beam

Innovative technologies in the modern manufacturing industry have called on the use of advanced welding techniques that extend the boundaries of the traditional arc welding technique. Laser welding applies very intensified concentrate light in the making of a very lean welding point with minimal zone of effect of heat. The technology is well suited to applications where high order of distortion is not permissible as is the case with electonic components, medical equipment, precision equipment.

Electron beam welding is done in a vacuum and is a process in which a welding weld that is very narrow and very deep is done by a narrow beam of high velocity electrons. It has the advantage that materials as thick as several inches can be welded with essentially one pass (usually by the pulsed method) and with little heat input, which makes it useful in thick-section welding where the disturbance of the welded parts must be minimised. This technology is especially beneficial in the Aerospace and the nuclear industries.

These newer processes have a high capital cost, specialized facilities but unsurpassed evaluation and repeatability. With the manufacturing needs shifting to better edge preparation quality and small tolerance levels, such technologies are gaining a heightened importance in terms of retaining competitive edge in the global markets.

Choosing the Right Welding Process: Factors to Consider

The choice of the welding process involves many details and factors that have to be particularly considered in every case. Type and thickness of material is a predominant consideration since the different processes only have the ability of joining specific thicknesses and metals. Collaboration in the design process and access inhibits process choice, with certain methods being more appropriate in restricted locations or a joint with a distinctive shape.

The need of production plays an important role on the choice of the process, where material thickness and quality needs must be considered and a balance between the quality needs and the productivity requirements has to be made. Applications requiring large quantities may benefit more by automated methods such as MIG or flux-cored welding, whereas precision work once again may necessitate the best quality provided by TIG welding, even though it is low quantity. Economic factors comprise the expenses of equipment, the expenses of consumable goods and the labour demands.

The viability of the processes is influenced by such factors in the environment as inside welding or outside, wind direction, and lack of space. Such position needs as flat, horizontal, vertical, or overhead affect the applicability of any processes. Levels of skill of the welders and also the amount of training needed in the various processes is also a very important factor in process selection as there are processes that require much more experience and training than others.

Future Trends in Welding Technology

The welding industry is an industry that is constantly undergoing changes propagated by the use of technology and is making it easier to achieve quality, productivity, and safety. Robotics and automation are also getting welding tasks that are repetitive and they offer better quality continuously with less chances of subjecting human workers to the harsh environment. The collaborative robots are configured to operate in conjunction with human welders where the automation efficiency is mixed with the human flexibility.

Digital measurement and control systems give real-time feedback of welding parameters and thus corrections can be made at any time and weld quality can be recorded. Machine learning and artificial intelligence algorithms process welding data, finding optimum parameters and being able to make predictions on the possible defects. These are the technologies that play a role in manufacturing Industry 4.0 revolution.

Welding technology-based additive manufacturing finds new frontiers with complex geometries that cannot be achieved with conventional manufacturing techniques. Wire arc additive manufacturing is a process that constructs metal parts on a larger scale by using both welding activities with computer guidance deposition systems and can make near-net-shape items with minimum scrap.

บทสรุป

Knowledge of different forms of welding processes is unique to people engaged in manufacturing, construction or repairs fields. Every welding technique has its own benefits and disadvantages which render it applicable to certain applications and situations. There is the versatility of MIG welding, the accuracy of TIG welding, the portability of corner joints stick welding, the productivity of submerged arc welding, and the specific application of corner welds each process is suited to an ideal outcome of any job.